Variate spray coating method for static electricity spraying robot with non-regulation planar polygon

An electrostatic spraying and polygonal technology, which is applied in the direction of the device and coating of the surface coating liquid, can solve the problems of uneven spraying, achieve the effect of reducing environmental pollution, reducing the total amount of coating, and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0052] The present invention is further illustrated by the following examples, wherein embodiment 1 is a comparative example that does not adopt the variable spraying method of the present invention, and embodiment 2 adopts the variable spraying method of the present invention:

Embodiment 1

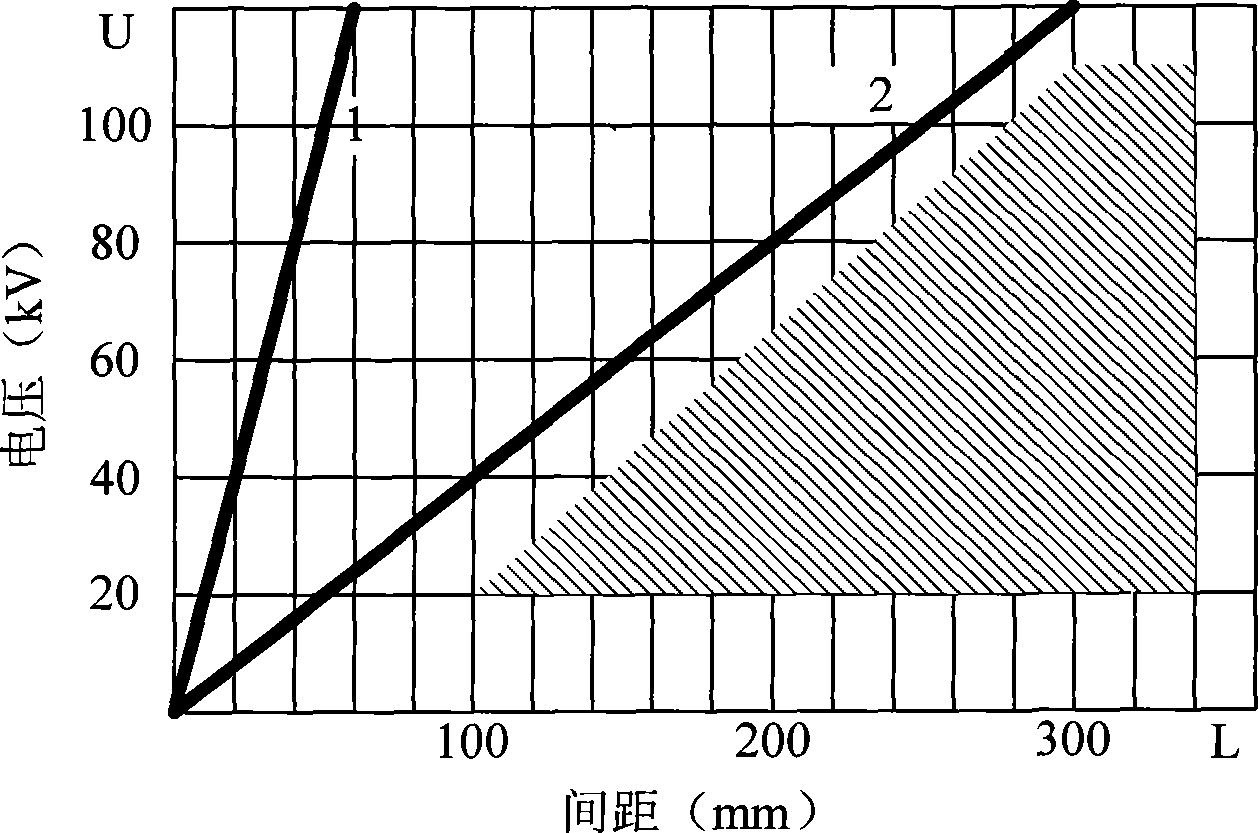

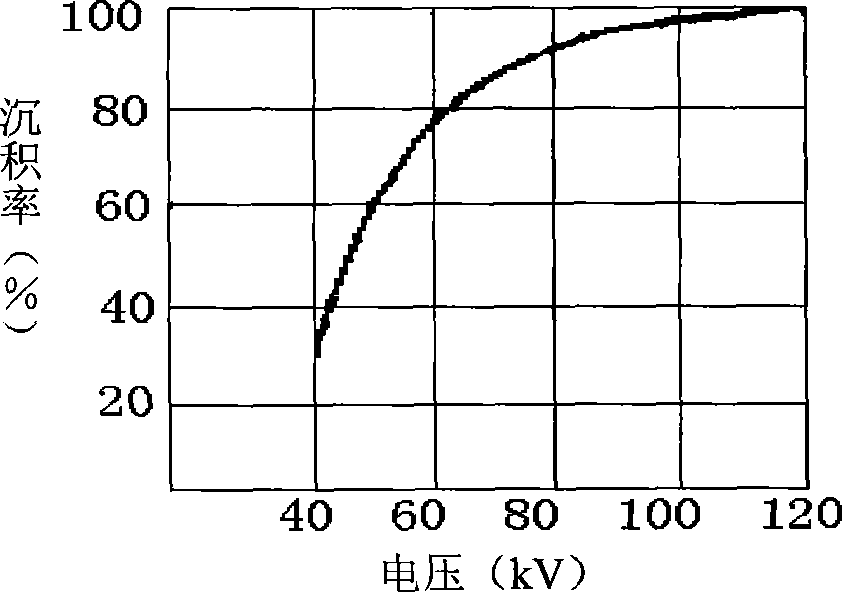

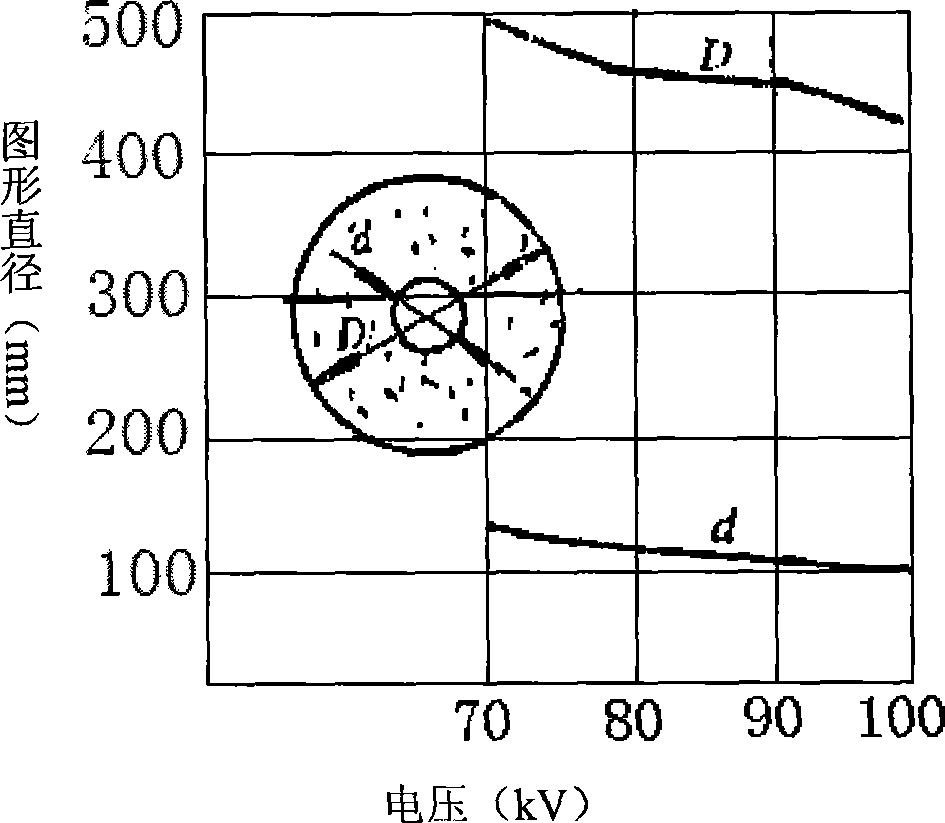

[0054] as attached Figure 6 The polygonal plane workpiece shown: AB=800mm, BE=3000mm, DE=1000mm, CD=1400mm, AC=1612mm, AB⊥BE, DE⊥BE, CD⊥DE; set the outer diameter of the maximum and minimum spray pattern that meets the spraying index It is: Dmax=500mm, Dmin=400mm.

[0055] Without considering the overlapping of spraying patterns, by adjusting the electrostatic voltage, spacing, rotating cup speed and translation rate so that the outer diameter of the pattern D=Dmax, the attached Figure 6 The workpiece shown is non-variable sprayed, and the cup trajectory (TCP) of the robot is shown in the attached Figure 7 As shown by the dotted line segment abcd, the path length S 0 =2*ab+2*ac=8000mm. Assuming that the coating thickness per unit area in the spray pattern is constant, assuming it is 1mm, the consumed paint C 0 =1×(2×ac×ab+ac×Dmax+π×Dmax2 / 4)=3946350mm 3 .

[0056] Example 2

[0057] Under the conditions of Example 1, the attached Figure 6 The workpiece shown was var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com