Hydrolysis-resistant dacron for dustproof clothes

A polyester fiber, anti-hydrolysis technology, applied in the field of polyester fiber, can solve dyeing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

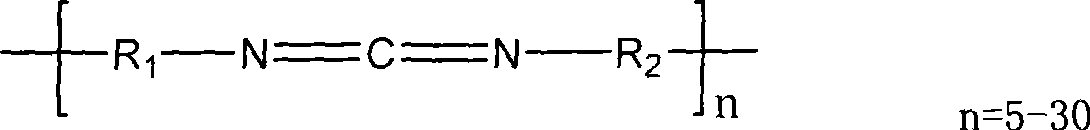

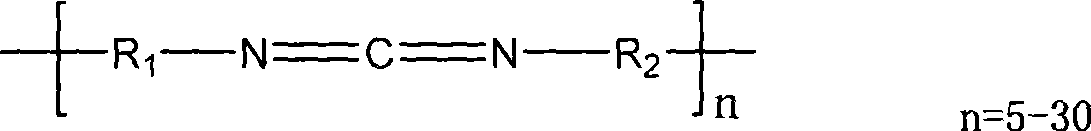

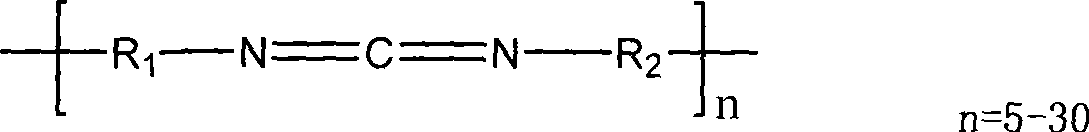

[0031] Mix polyester PET and polycarbodiimide according to different proportions, measure after melting, under the condition of total discharge speed 37g / min, spinning temperature 295 degrees, 72-hole φ0.28mmde mouth gold discharge spinning speed 3000m / min Down spinning obtains 140D-72 semi-drawn yarn with residual elongation of 150%. The semi-stretched yarn is stretched at an extension temperature of 85 degrees, a heat setting temperature of 140 degrees, and an elongation ratio of 1.7 to obtain a stretched yarn of 84D-72 single filament fineness of 1.2dtex. The obtained stretched filaments were twisted at 1500T / M and used as warp and weft yarns of the fabric respectively to obtain a plain weave fabric with a processing density of 153 x 80 / 160 x 86, which was heat treated at 135 degrees for 100 times for 20 minutes. The polycarbodiimide contains N=C=N groups, and its structural formula is:

[0032]

[0033] R 1 , R 2 It is one or more of C1-C10 saturated or unsaturated a...

Embodiment 3

[0040] Levels 11-14 are based on the spinning conditions of level 1, using polycarbodiimides with different molecular weights, and the results are as follows.

[0041] 11 12 13 14

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com