Pretensioning method for converting old simply supported beam bridge into continuous bridge

A technology of simply supported girder bridges and supported girder bridges, which is applied to bridges, bridge materials, bridge maintenance, etc., and can solve problems such as many expansion joints and frequent driving bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

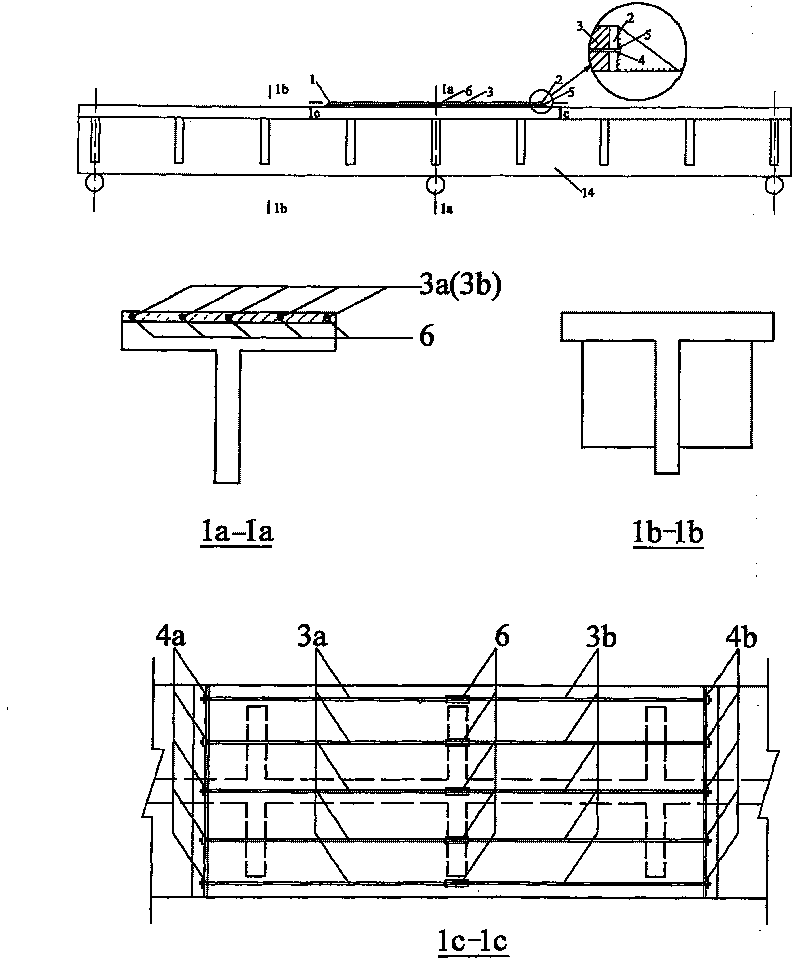

[0028] A pretensioning method for converting old simply supported girder bridges into continuous girder bridges:

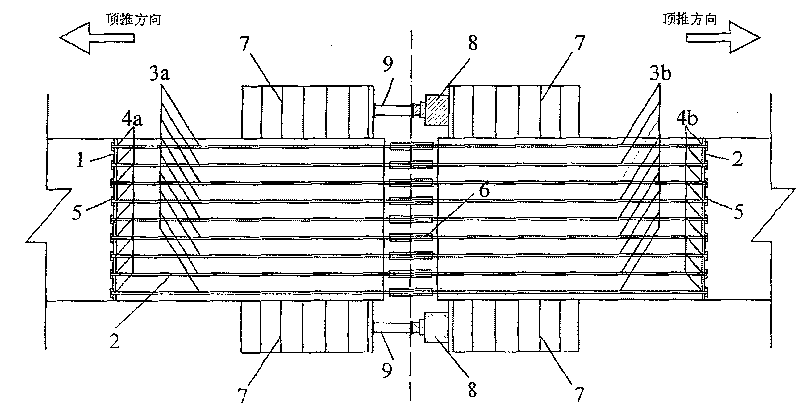

[0029] a. Embed vertically placed horizontal first steel plate 1 on one side of the end that needs to be connected in the longitudinal direction of old simply supported T-beam 14, and embed vertically placed horizontally second steel plate 2 on the other side, and lay connection pre-installation on the steel plate. The position of the stress tendons 3 is drilled in advance, and the size of the holes can pass through the prestress tendons 3,

[0030] B. in the hole 4a of the first steel plate, penetrate the prestressed tendon 3a, also penetrate the prestressed tendon 3b in the hole 4b of the second steel plate, will be positioned at the prestressed tendon outside the area between the first steel plate and the second steel plate One end of the tendon is anchored with a heading anchor 5, and the other end of the prestressed tendon passing through the first steel plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com