Casing, method and mold for fabricating the same

A shell and mold technology, which is applied in household appliances, other household appliances, electrical equipment casings/cabinets/drawers, etc., can solve the problems of display window wrinkles, roughness, substrate and display window surface roughness, etc., and eliminate wrinkles , Improve quality and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

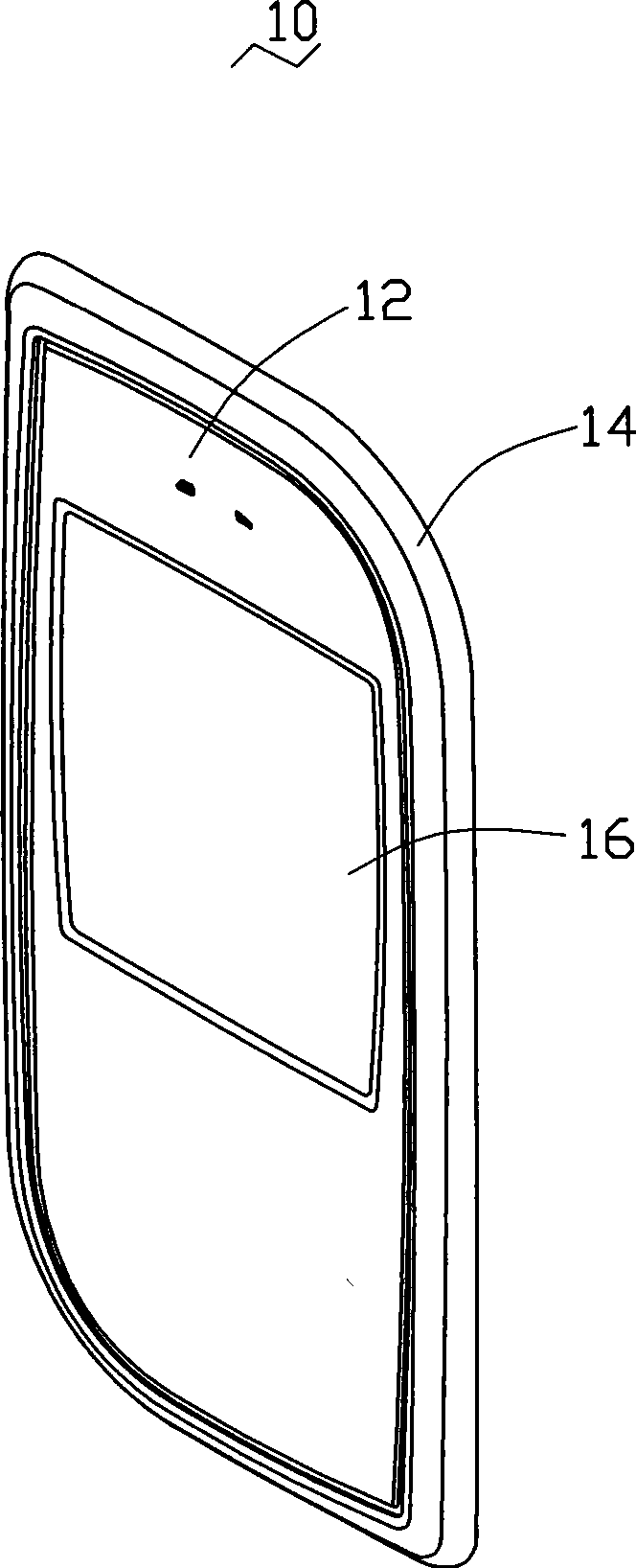

[0019] see figure 1 , a casing 10 of an electronic device according to a preferred embodiment of the present invention, the casing 10 includes a film 12 , a substrate 14 and a display window 16 . The film 12 covers the surface of the substrate 14 and the display window 16, the film 12 is a transparent film, and can be made of resin, glass, fiber or polymer material; the film 12 makes the housing 10 present a smooth surface, And make the surface of the housing 10 have better wear resistance. Numbers, characters, or patterns can be printed on the surface of the film 12 to decorate the casing 10 . The base 14 constitutes the main part of the casing 10 and can be made of common plastics. The base 14 defines an opening (not shown), and the display window 16 is formed on the base 14 corresponding to the opening. The material of the display window 16 is different from that of the base body 14, and the display window 16 can be made of a transparent injection resin material, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com