Method for processing complex large-sized plastic rubber panel appearance surface decoration

A technology of surface decoration and treatment method, applied in the coating and other directions, can solve the problems of complex process, high bending height, increased difficulty, etc., to achieve the effect of enhancing the appearance effect, avoiding wrinkles, and improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

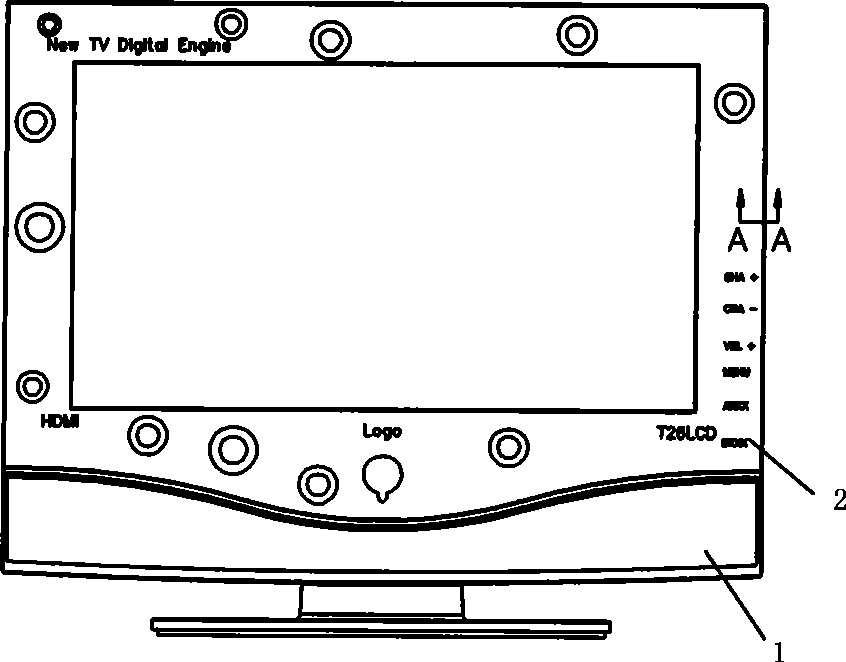

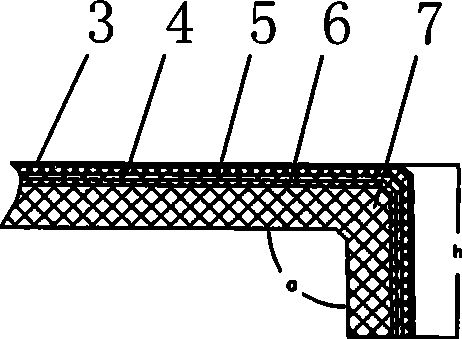

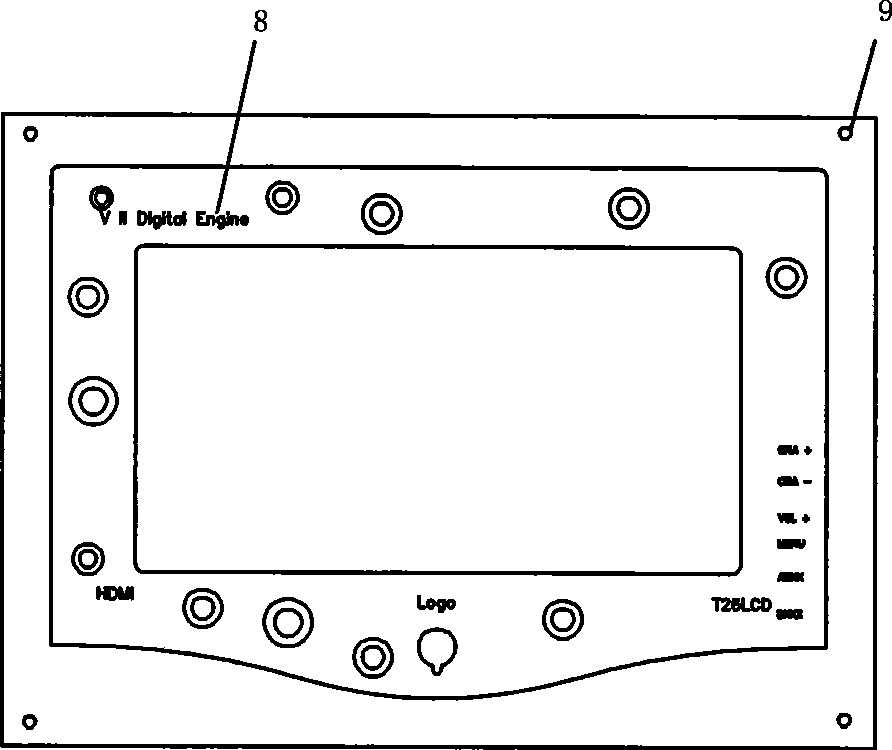

[0018] The present invention relates to a complex and large-scale plastic panel appearance surface decoration treatment method. According to the designed product appearance, pattern and text, it is extended into a plane drawing, and a film diaphragm is made according to the drawing, and the corresponding pattern is printed on the inner surface of the film diaphragm. and characters to form a printing layer, and then cover an adhesive layer on the outer surface of the printing layer to make a film sheet; according to the shape and development characteristics of the product, make a metal mold for punching the film sheet, and punch the outer edge of the film sheet and inner hole, retain the film sheet required for molding; according to the shape structure of the product, make a film sheet shaping mold, shape the film sheet to obtain the shaped film sheet of the required shape; design and develop the injection mold according to the structure of the product, put it into Shape the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com