Catalyst for chemically enhancing glass, preparation and use thereof

A technology of glass strengthening and catalyst, which is applied in chemical catalyst composition and its application field, can solve the problems of low impact resistance of glass and long time of strengthening process, etc., and achieve the effect of increasing compressive stress and glass strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The parts by weight of each component of the catalyst:

[0042] Component A: Potassium Hydroxide 2 Component B: Potassium Silicate 20

[0043] Component C: potassium chromate 80 potassium carbonate 50

[0044] Preparation method of glass strengthening fluid:

[0045] In step a, component B potassium silicate is added to the potassium nitrate molten salt in the strengthening furnace 1 and heated and melted for 4 hours to form the first molten salt mixture;

[0046] In step b, potassium carbonate and component C potassium chromate are respectively added to the first molten salt mixture and heated and melted for 1 hour to form a second molten salt mixture;

[0047] In step c, the potassium hydroxide of component A is added to the second molten salt mixture, heated and melted, and then left to stand for 2 hours to obtain a glass strengthening liquid.

[0048] Wherein the weight ratio of potassium nitrate molten salt to catalyst is 1:99.

[0049] The method of using this...

Embodiment 2

[0053] The parts by weight of each component of the catalyst:

[0054] Component A: Potassium Hydroxide 2 Component B: Potassium Silicate 50

[0055] Component C: Potassium Phosphate 50 Potassium Carbonate 50

[0056] Preparation method of glass strengthening fluid:

[0057]In step a, component B potassium silicate is added to the potassium nitrite molten salt in the strengthening furnace 1 and heated and melted for 2 hours to form the first molten salt mixture;

[0058] In step b, component C potassium phosphate and potassium carbonate are respectively added to the first molten salt mixture and heated and melted for 4 hours to form a second molten salt mixture;

[0059] In step c, the potassium hydroxide of component A is added to the second molten salt mixture, heated and melted, and then left to stand for 6 hours to obtain a glass strengthening liquid.

[0060] Wherein the weight ratio of potassium nitrite molten salt to catalyst is 1.9:98.1.

[0061] The method of usin...

Embodiment 3

[0065] The parts by weight of each component of the catalyst:

[0066] Component A: Potassium Fluoride 1 Component B: Potassium Silicate 30

[0067] Component C: potassium permanganate 70 potassium carbonate 10

[0068] Preparation method of glass strengthening fluid:

[0069] In step a, the component B potassium silicate is added to the potassium nitrate and potassium chloride molten salt in the strengthening furnace 1 and heated and melted for 1 hour to form the first molten salt mixture;

[0070] In step b, component C potassium permanganate and potassium carbonate are respectively added to the first molten salt mixture and heated and melted for 5 hours to form a second molten salt mixture;

[0071] In step c, the potassium fluoride of component A is added into the second molten salt mixture, heated and melted, and then left to stand for 2 hours to obtain a glass strengthening liquid.

[0072] Wherein the weight ratio of potassium nitrate molten salt to catalyst is 1.7:9...

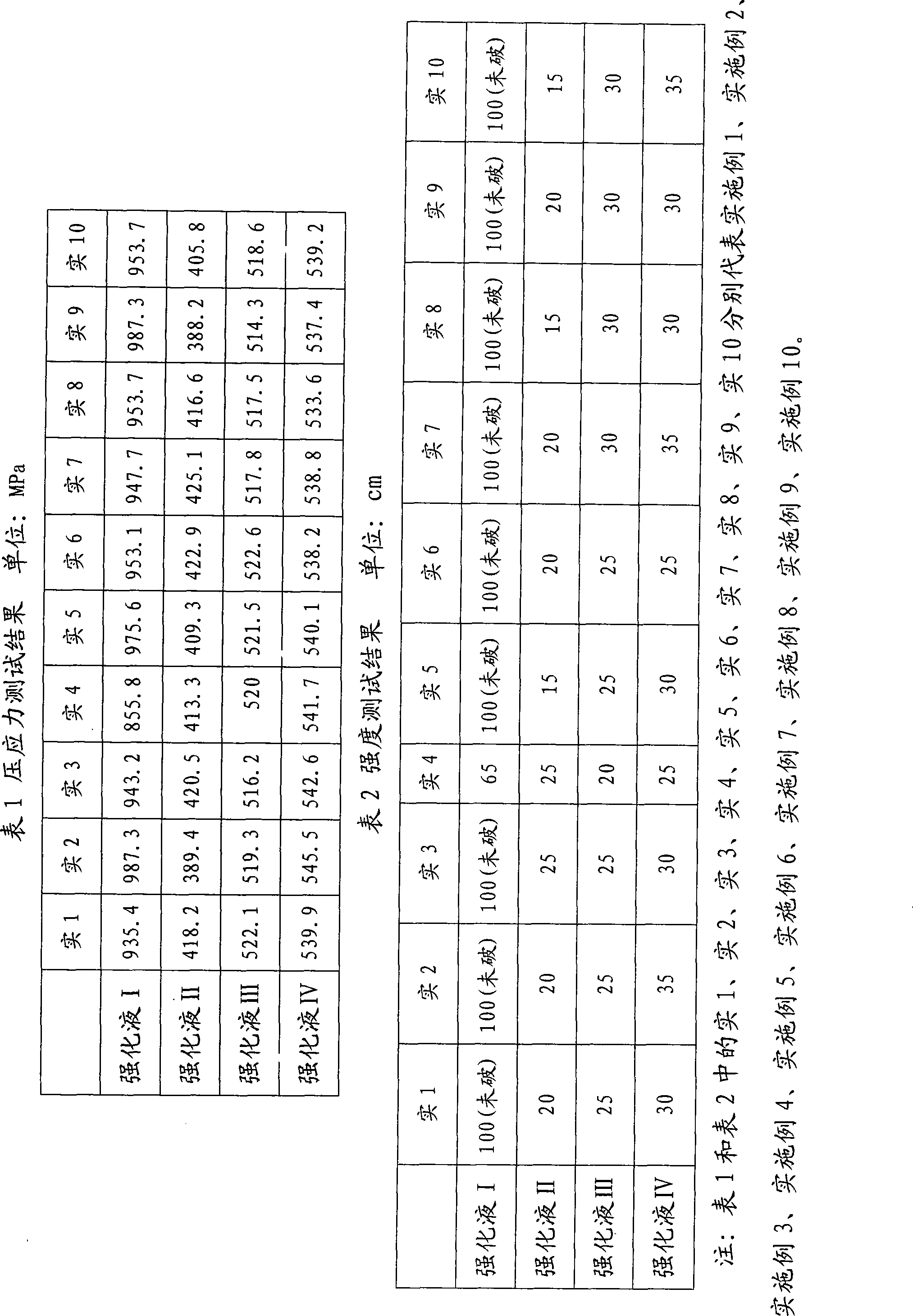

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com