Method of and apparatus for monitoring flow of lubricant vapor forming lubricant coatings of magnetic disks

A technology of lubricant and steam, which is applied in the field of monitoring the mass flow rate of lubricant steam flowing through the steam to the vacuum chamber, and can solve the problems of interruption, waste and inefficiency of manufacturing arrangements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

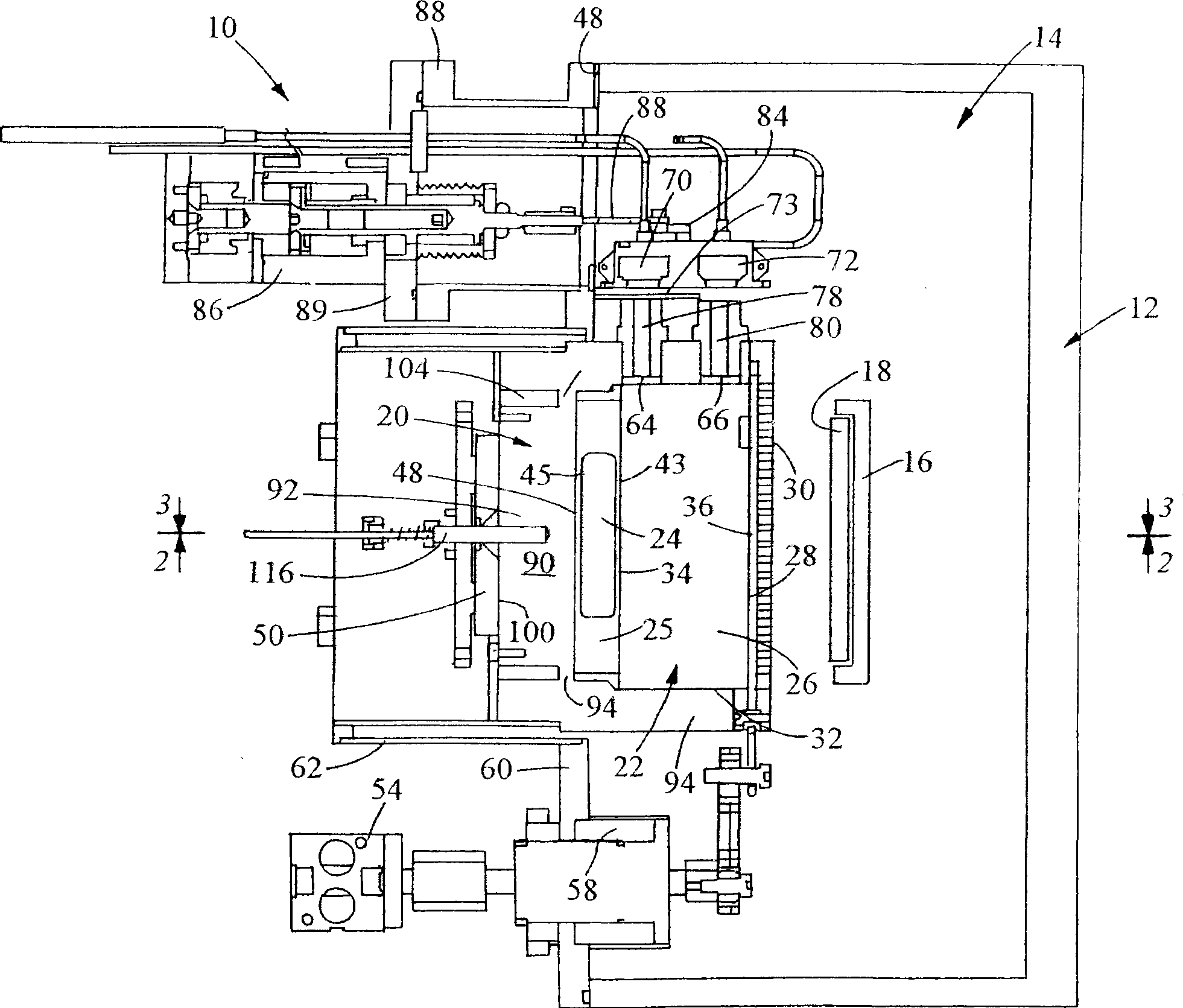

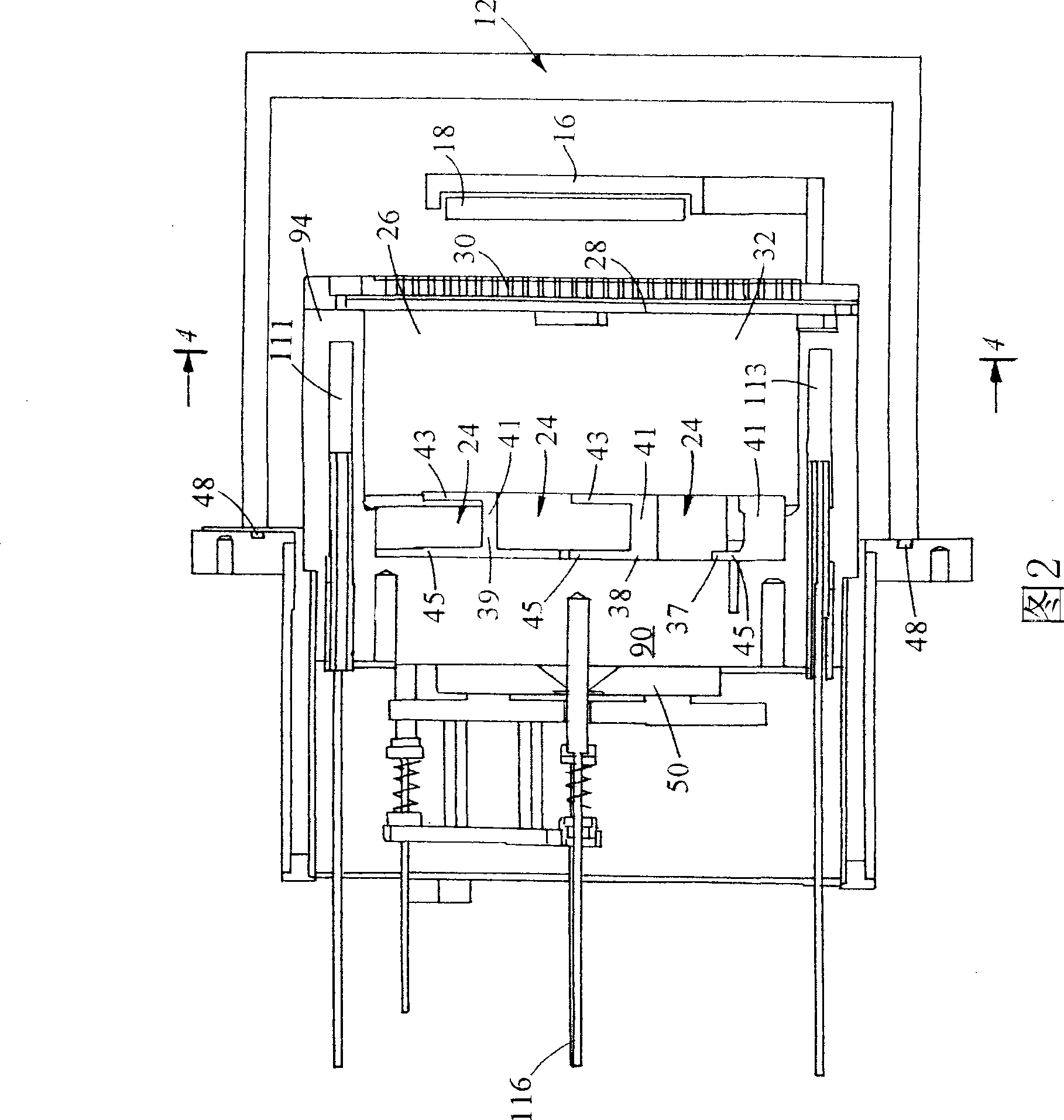

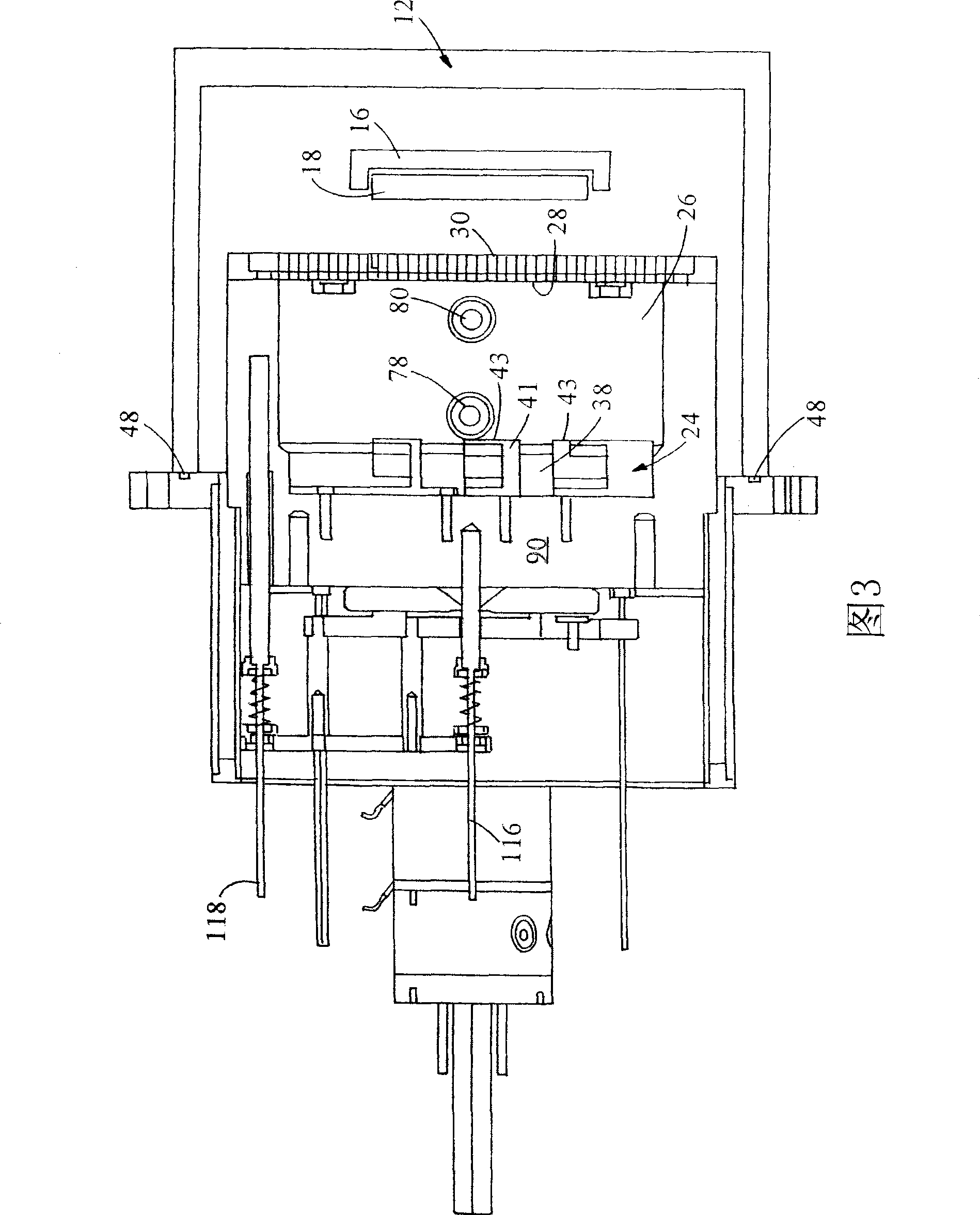

[0020] Reference is now made to the drawings containing a source 10 of lubricant (commonly referred to as oil) and a housing 12 containing a vacuum chamber 14 maintained at a suitable vacuum pressure by a suitable vacuum pump (not shown). Located in the chamber 14 is a holder 16 for a rigid magnetic disk 18 comprising a substrate covered alternately by layers of chromium and magnetic layers, as disclosed in the aforementioned patent. Subsequently, the holder 16 lifts the different rigid disks from the cassettes that move in and out of the vacuum chamber 14 to move the disks as figure 1 The location shown in -3, is deposited in the channel of the lubricant vapor on the disc. The lubricant is preferably PFPE.

[0021] Source 10 comprises an atmospheric portion 20 maintained at atmospheric pressure and a vacuum portion 22 maintained to have the same vacuum as in chamber 14 by a gas flow path often present between vacuum portion 22 and chamber 14. of vacuum pressure. A liquid l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com