Substrate and method for mounting silicon device

A technology for silicon devices and substrates, which is applied in the manufacture of semiconductor devices, electric solid-state devices, and semiconductor/solid-state devices, etc., and can solve problems such as the inability to provide stable support for the second component.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

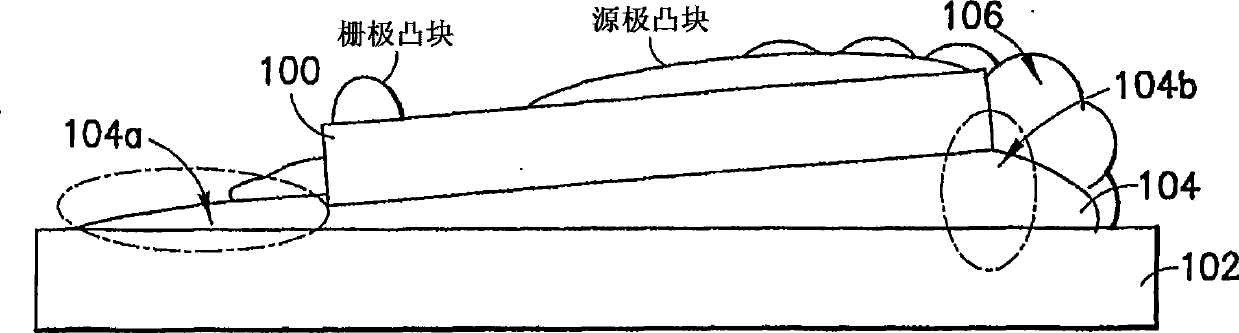

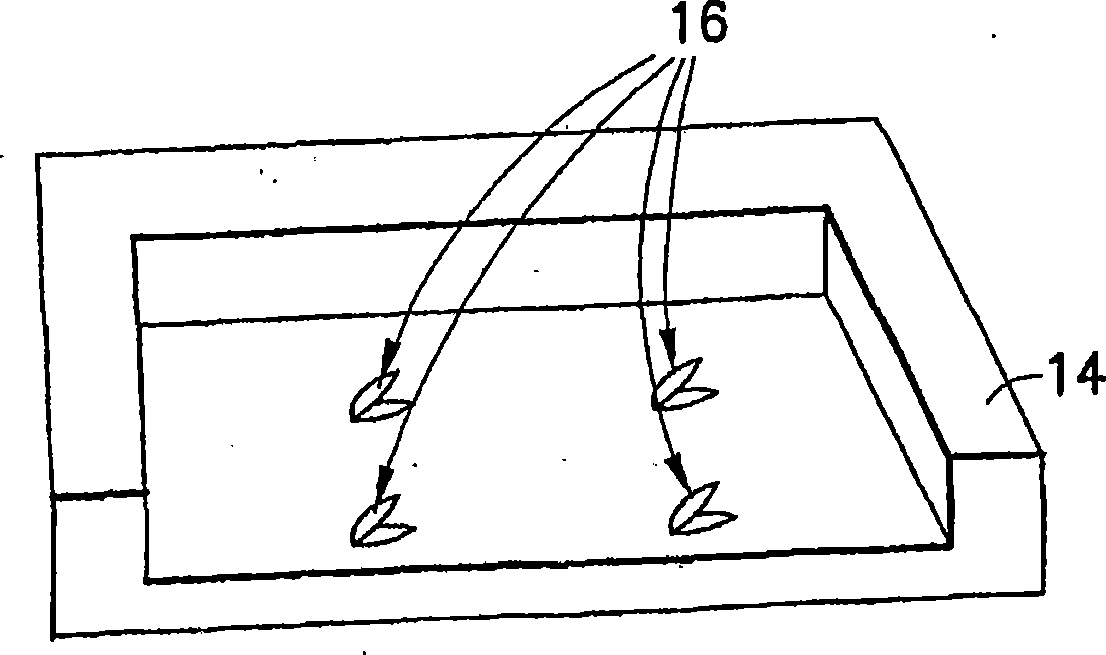

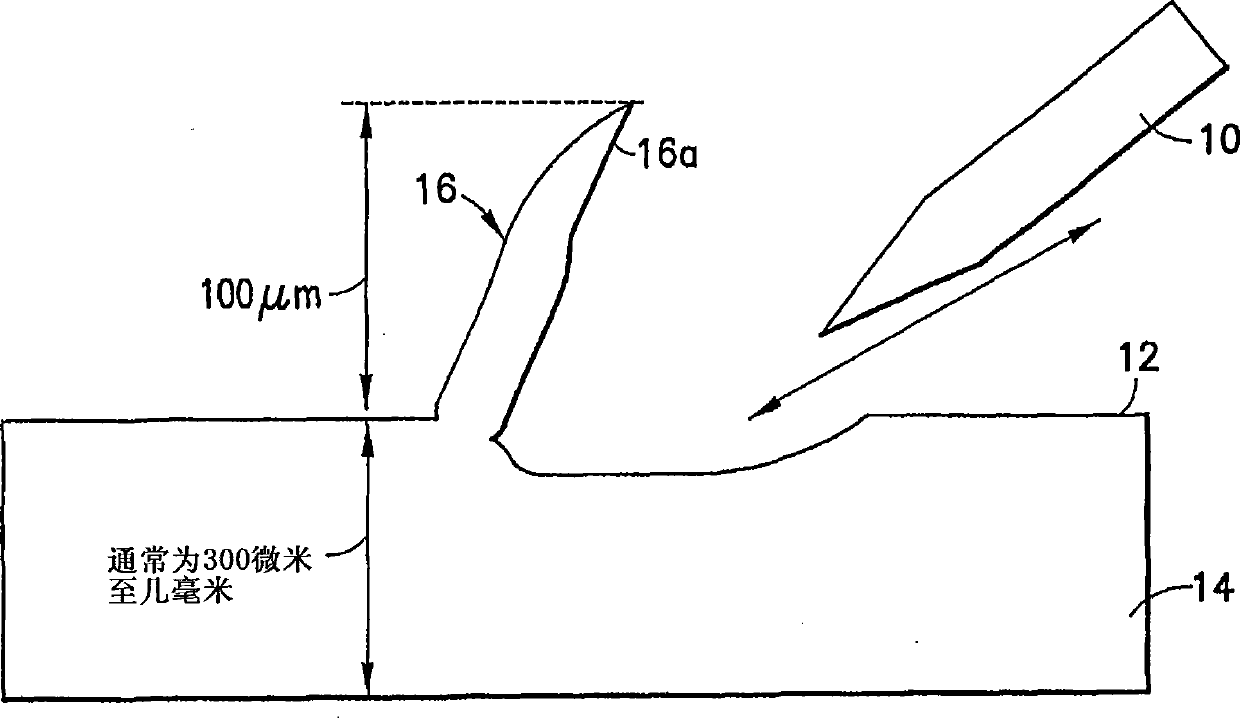

[0032] For example, in this application's Figure 2-6 A substrate with a Si device or chip mounted thereon in accordance with an embodiment of the present invention is shown in . In a preferred embodiment, as image 3 As shown, needle tool 10 is used to gouge on top metal surface 12 of substrate 14 to form substantially vertical protrusions 16 (or swarfs) extending upwardly from surface 12 of substrate 14 . As shown, the protrusions 16 preferably have a height of about 100 μm. While this is the preferred height for the protrusions 16, the height of the protrusions can be modified to suit a particular application.

[0033] In a preferred embodiment, the substrate 12 is a metal can such as Metal cans used in product lines, or Cu layers such as the horseshoe-shaped DBC described above in the co-pending application entitled PACKAGE FOR HIGH POWER DENSITY DEVICES. However, protrusions 16 can equally be formed on any substrate, if desired. In a preferred embodiment, as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com