Progressive indirect evaporation cooler

An evaporative cooler, progressive technology, applied in the field of renewable energy, can solve the problems of low heat exchange efficiency, large pressure drop, large unit size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

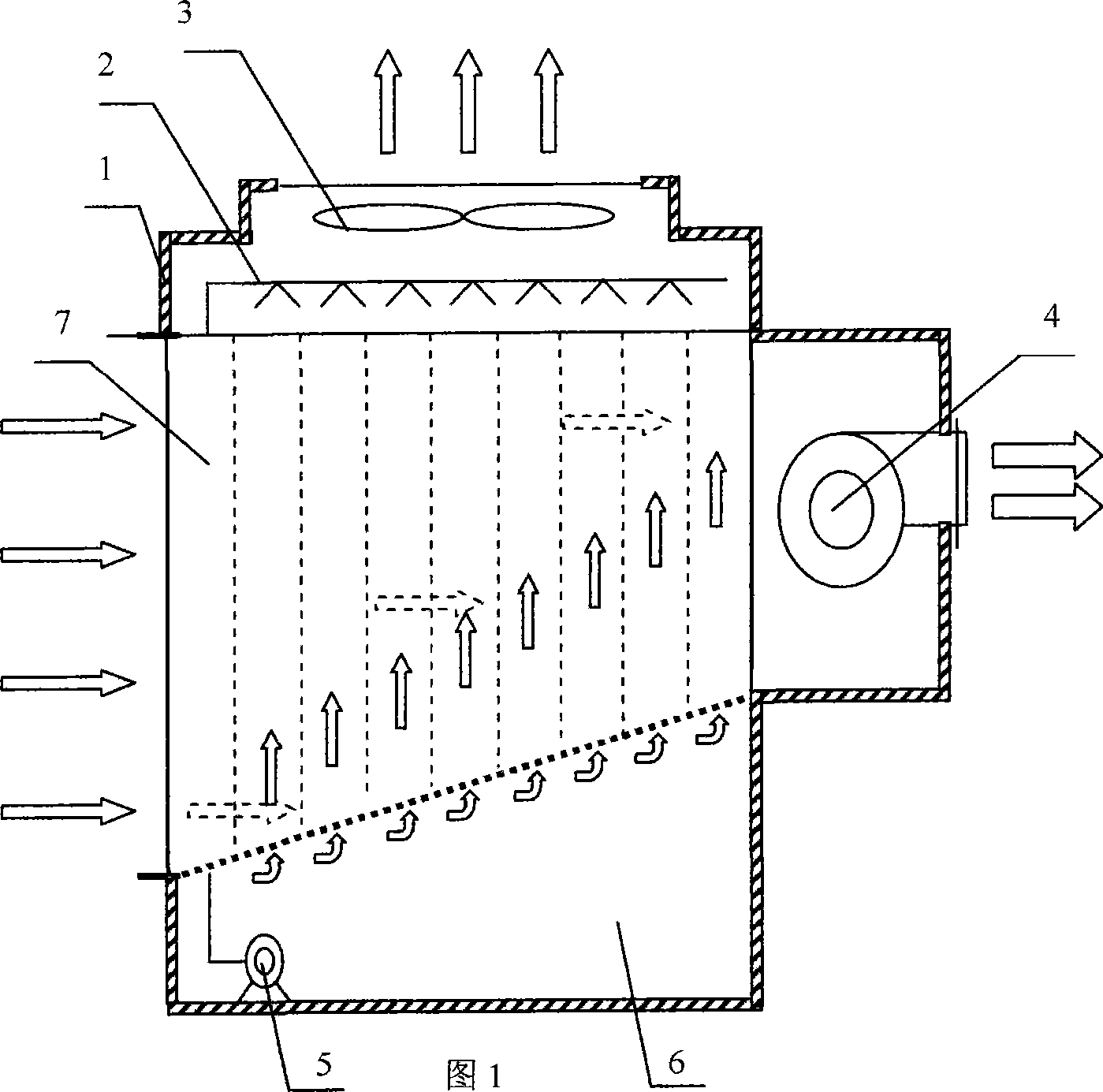

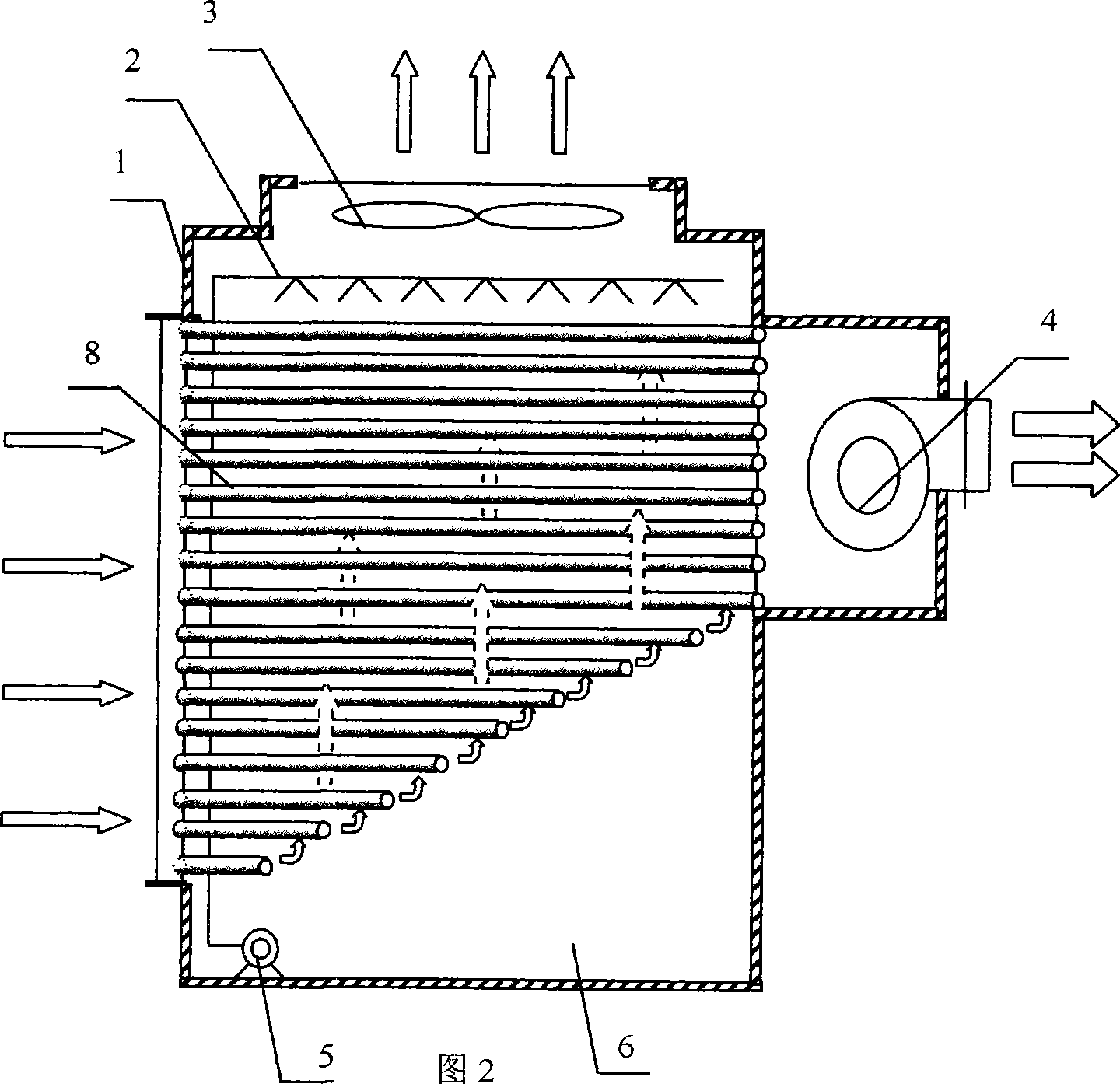

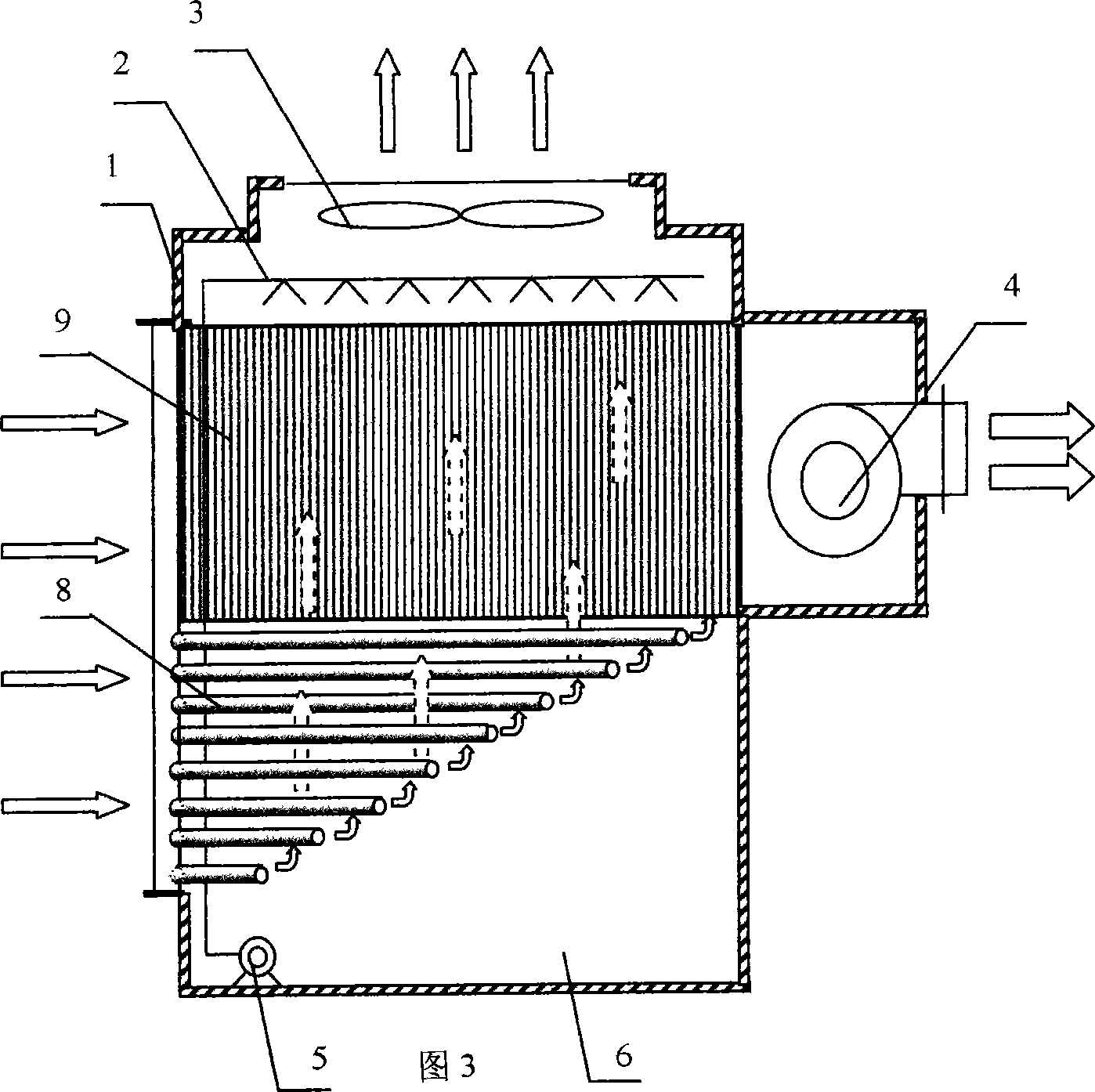

[0026] A kind of progressive indirect evaporative cooler, embodiment 1 shown in Fig. An induced draft fan 4 is installed on the tuyere, an exhaust fan 3 is installed on the outlet of the secondary air, an indirect evaporative cooler is installed in the casing 1, a water distributor 2 is arranged above the indirect evaporative cooler, and a water distributor 2 is installed below it. A water tank 6 is provided to supply water to the water distributor 2 through a water pump 5. The indirect evaporative cooler is a horizontal plate-type indirect evaporative cooler 7, and its dry channel is a horizontal channel. The horizontal projection of the plate-type indirect evaporative cooler 7 is a right-angled trapezoid. The secondary air supply surface of the plate-type indirect evaporative cooler 7 is an inclined surface, and the dry passages on the inclined surface are elongated from near to far, so that the once-humid cooling The air flow is divided into primary air and secondary air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com