Edge sensor and flaw detection apparatus

A sensor and defect detection technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of influence, difficulty in clearly detecting the change of edge position, and difficult detection of edges, etc., and achieve the effect of great practical advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, an edge sensor and a defect detection device using the edge sensor according to an embodiment of the present invention will be described with reference to the drawings.

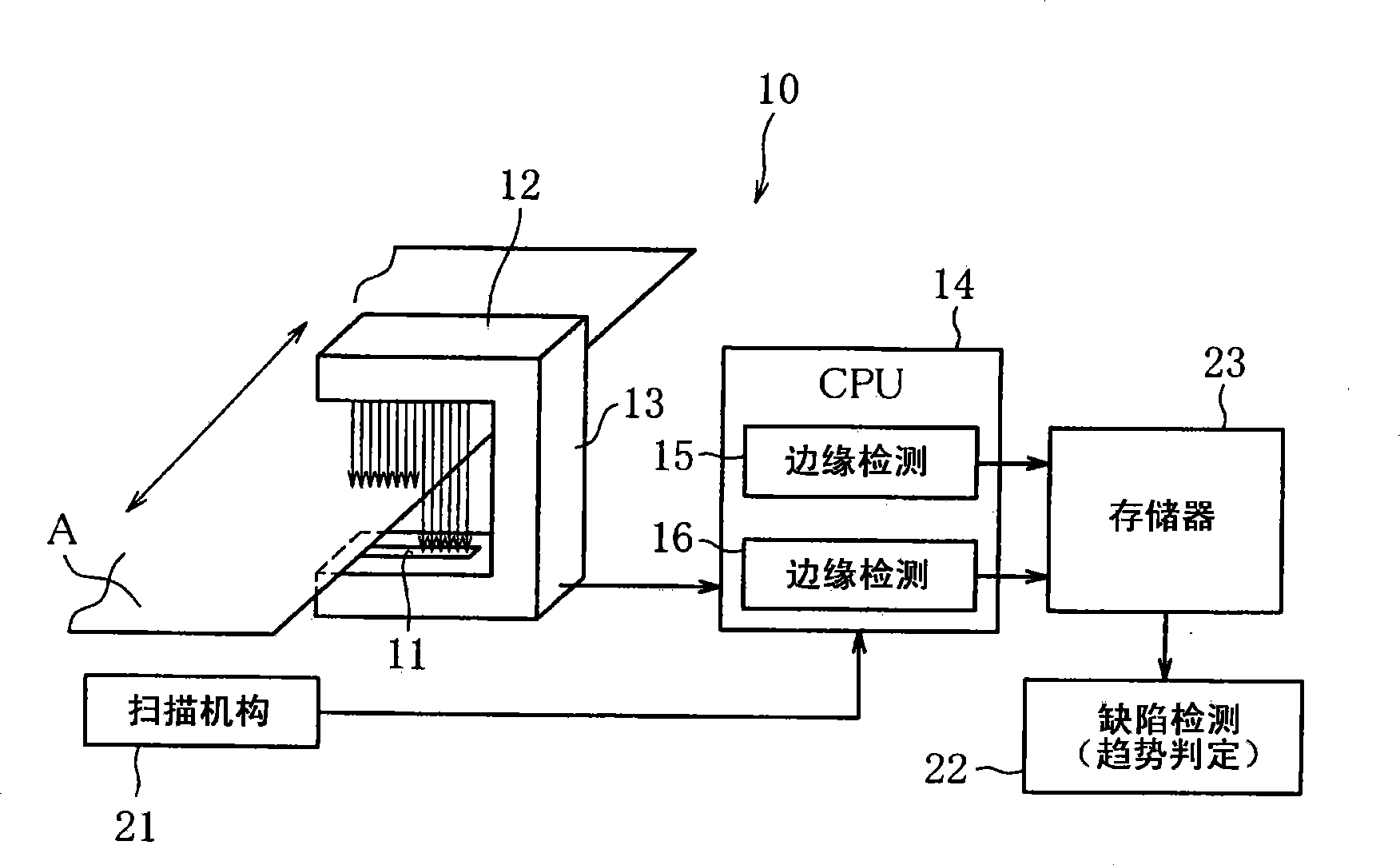

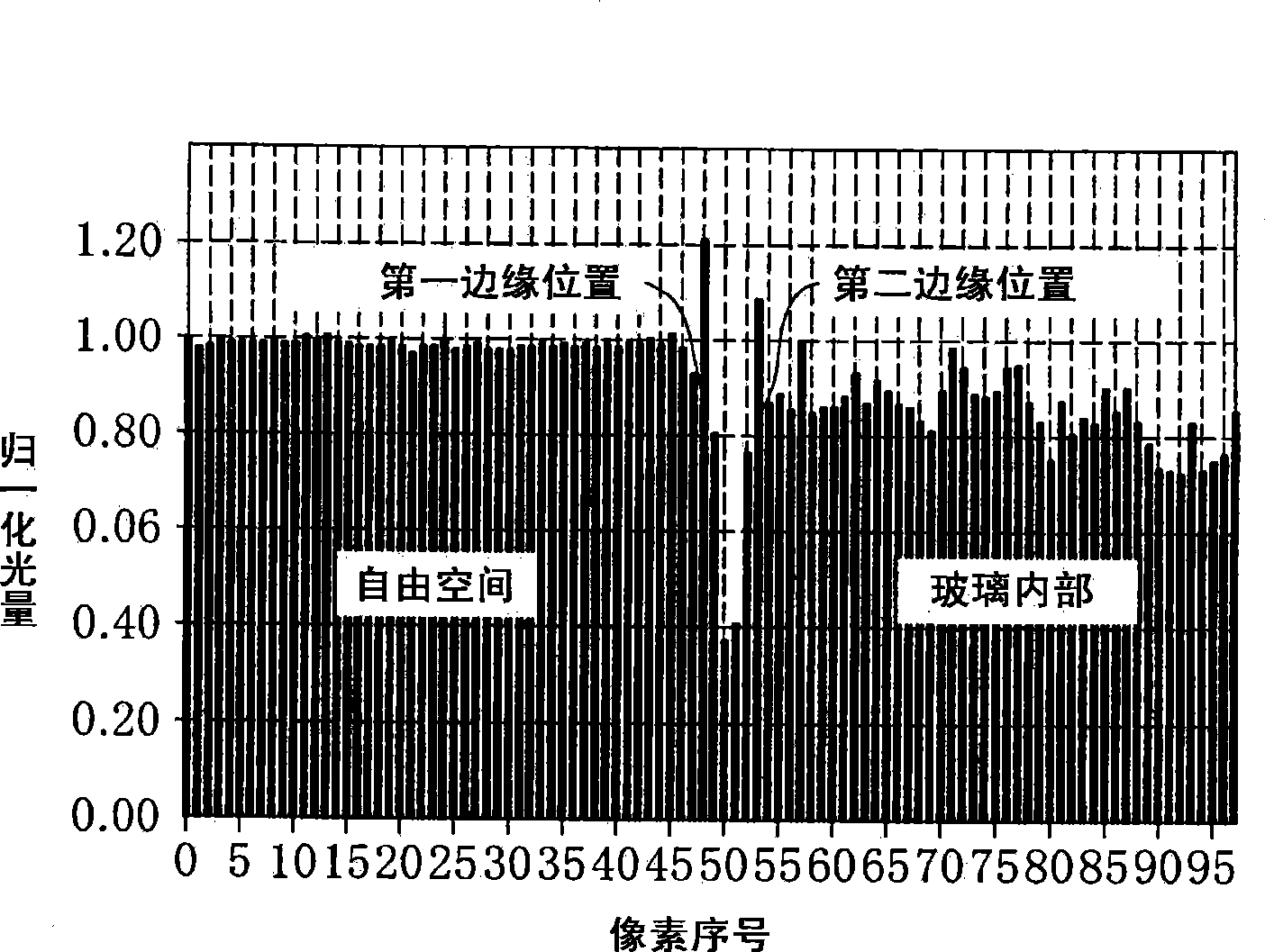

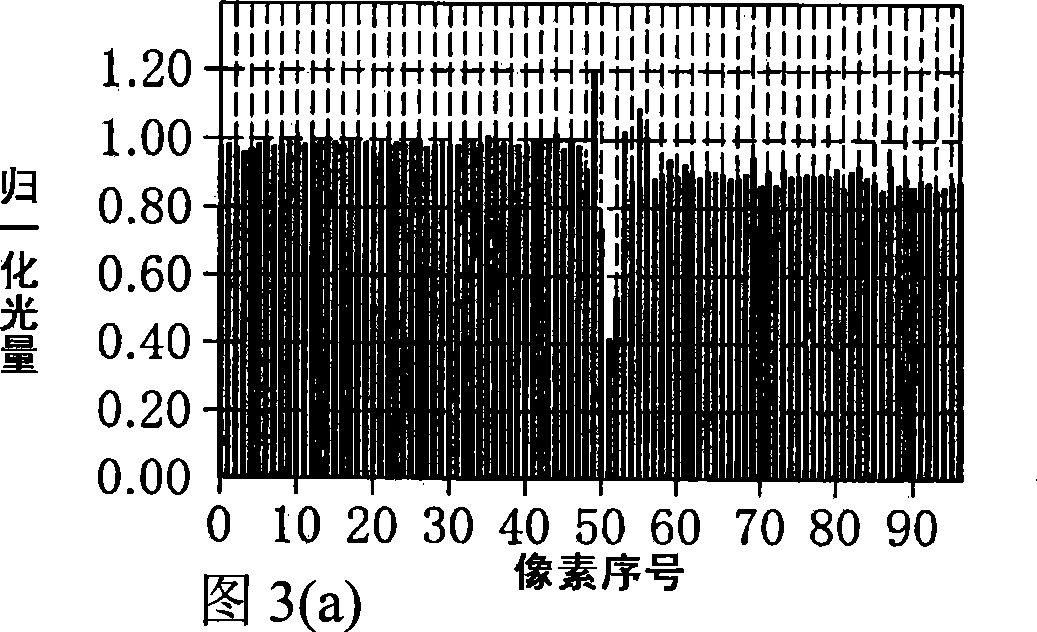

[0042] figure 1 An edge sensor 10 that detects a specific position (for example, an edge position) of a transparent or translucent object A such as liquid crystal glass, and monitors the output of the edge sensor 10 while scanning the position detection target portion of the object A using the edge sensor 10 This is a general configuration diagram of a defect detection device for detecting the presence or absence of defects in the above-mentioned object A.

[0043] The edge sensor 10 includes the following components: an optical head 13, which separates a line sensor 11 formed by arranging a plurality of photosensitive units in a line at a predetermined interval from a light source 12 that projects monochromatic parallel light toward the line sensor 11 by a predetermined distance. distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com