Perpendicular magnetic recording medium and magnetic recording and reproducing apparatus using the same

一种垂直磁记录、磁记录介质的技术,应用在磁记录、数据记录、记录信息存储等方向,能够解决记录/再现特性降低、有限、增大介质噪音等问题,达到记录分辨率降低抑制、高读取信号质量、高热搅动阻抗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

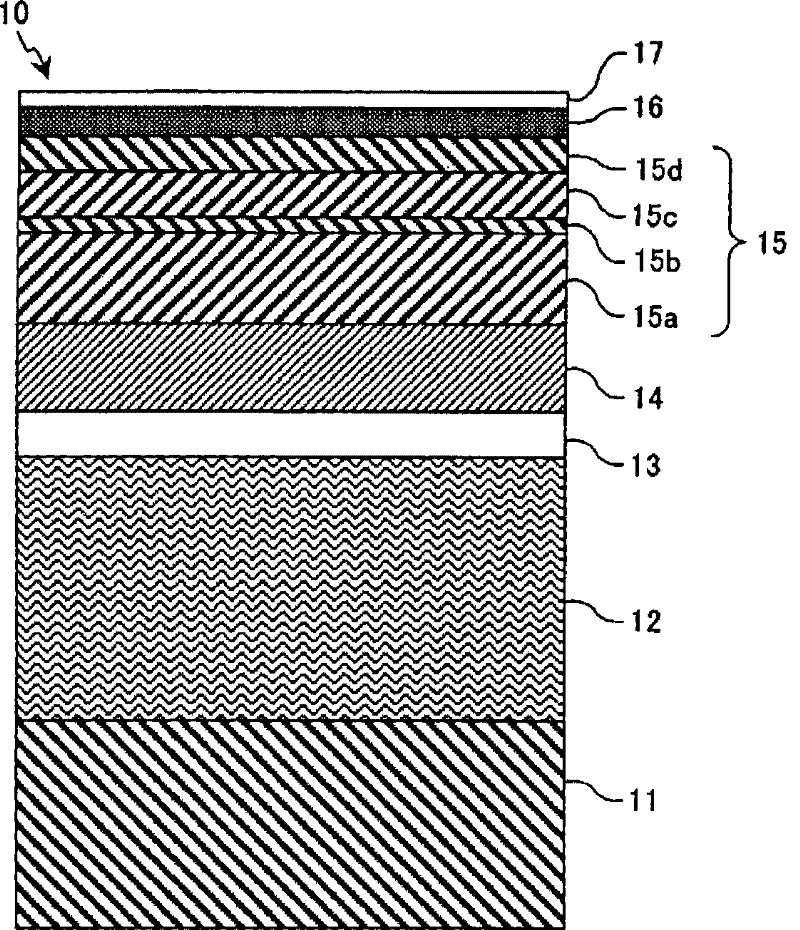

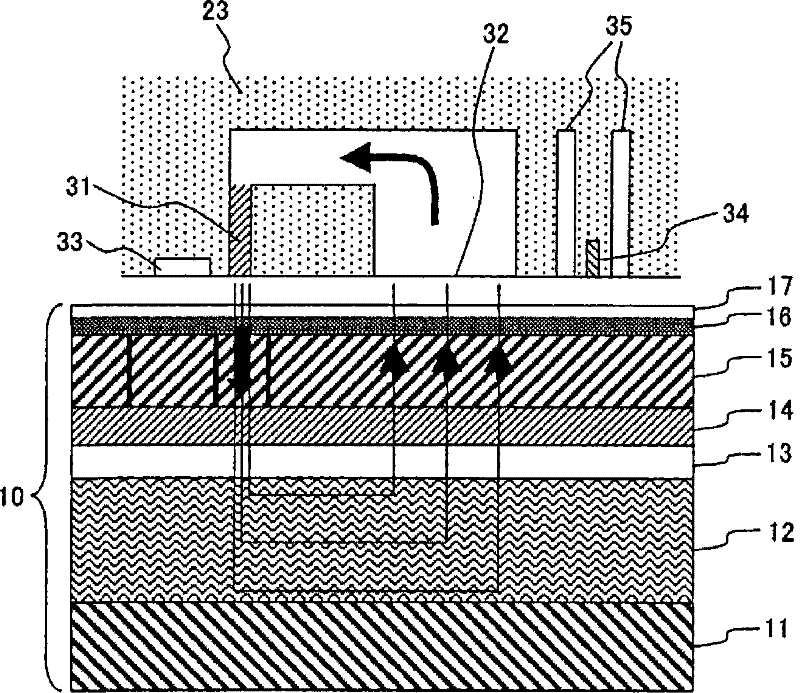

[0132] By the DC sputtering method using an in-line sputtering device, a multilayer thin film was formed on a clean strengthened glass substrate of the magnetic disk. As a multilayer film, first by using AlTi 50 target (the subscript values show here and hereinafter the atomic % of the content of the elements in the alloy) to prepare an AlTi amorphous alloy layer with a thickness of 30 nm. Next, by using FeCo 34 Ta 10 Zr 5 target to prepare the soft magnetic amorphous film to 30nm, to prepare the antiferromagnetic coupling film to 0.5nm by using the Ru target, and again to use the FeCo 34 Ta 10 Zr 5 target to prepare the soft magnetic amorphous thin film with a thickness of 30nm to form a soft magnetic back pad layer 12 with a three-layer stacked structure. The processing gas for each of the above layers during film formation was Ar and the gas pressure was 1 Pa. In addition, sequentially under the Ar pressure of 2Pa by using NiW 8 target to prepare the NiW alloy see...

Embodiment 2

[0145] By utilizing the following with figure 1 Magnetic characteristics and recording / reproducing characteristics were measured in the same manner in the manufacturing steps and evaluation steps to manufacture perpendicular magnetic recording media. However, in Embodiment 2, the magnetic coupling layer 15b is made of CoCr having a thickness of 1.8nm 30 alloy, and the second magnetic layer 15c is made by using CoCr 17 Pt 13 -SiO 2 (8mol%) mixed target preparation. Thereafter, in Example 2, samples were fabricated while setting the sum of the thickness t2 of the second magnetic layer 15c and the thickness t3 of the third magnetic layer 15d constant and varying the ratio of t2. Figure 5A list is given of the composition, saturation magnetization Ms, and thickness of each layer constituting the magnetic recording layer of the produced perpendicular magnetic recording medium.

[0146] Figure 15 is a view showing the relationship between the ratio t2 (t2+t3) of the thicknes...

Embodiment 3

[0153] By utilizing the following with figure 1 Magnetic characteristics and recording / reproducing characteristics were measured in the same manner in the manufacturing steps and evaluation steps to manufacture perpendicular magnetic recording media. However, in Example 3, the magnetic coupling layer 15b is made of CoCr having a thickness of 1.2nm 25 Cr 10 alloy, and the second magnetic layer 15c is made by using CoCr 17 Pt 13 -SiO 2 (8mol%) mixed target preparation. Thereafter, in Embodiment 3, the thickness t2 of the second magnetic layer 15c and the thickness t3 of the third magnetic layer 15d are made the same (t2=t3), and the sum of the thicknesses of the second magnetic layer 15c and the third magnetic layer 15d ( t2+t3) were varied to form samples. Figure 6 A list is given of the composition, saturation magnetization Ms, and thickness of each layer constituting the magnetic recording layer of the produced perpendicular magnetic recording medium.

[0154] Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| magnetization | aaaaa | aaaaa |

| magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com