System, method, and apparatus for enhancing the durability of earth-boring

A drill bit and drill bit body technology, applied in the field of drill bits, can solve the problems of expensive tungsten carbide and loss of expensive diamonds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] see figure 1 , one embodiment of a carbide crystal 21 constructed in accordance with the present invention is shown in simplified circular form. In the illustrated embodiment, crystals 21 are formed of tungsten carbide (WC) and have an average grain size ranging from about 0.5 to 8 microns, depending on the application. The term "average particle size" refers to the average diameter of particles that are slightly irregular in shape.

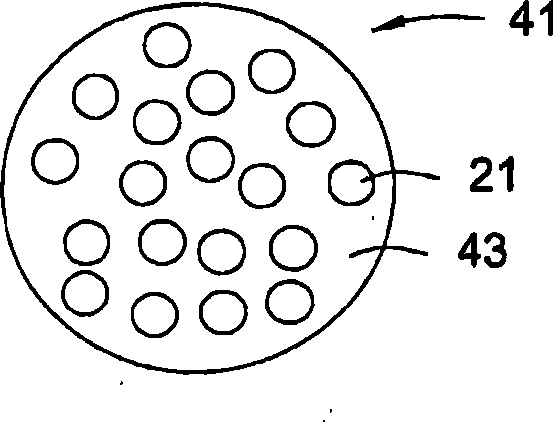

[0027] see now figure 2 , one example of crystal 21 is shown forming a sintered oblate spheroid pellet 41 . Neither crystals 21 nor pellets 41 are drawn to scale, they are shown in simplified form for reference purposes only. The invention should not be interpreted or limited by these descriptions. For example, other possible shapes include elongated or oval circular structures and the like.

[0028] The pellets 41 are suitable for use, for example, in case hardening for drill bits. Pellets 41 are formed from a plurality of crystals...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com