Flexible tube side-by-side high-speed, high-pressure squeezing and drying solid-liquid treatment device

A liquid processing and flexible tube technology, which is used in the field of liquid fuel production, can solve the problems of complicated mechanism for removing filter residues, affecting the speed of filtration and pressing, and inability to remove filter residues attached to filter membranes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

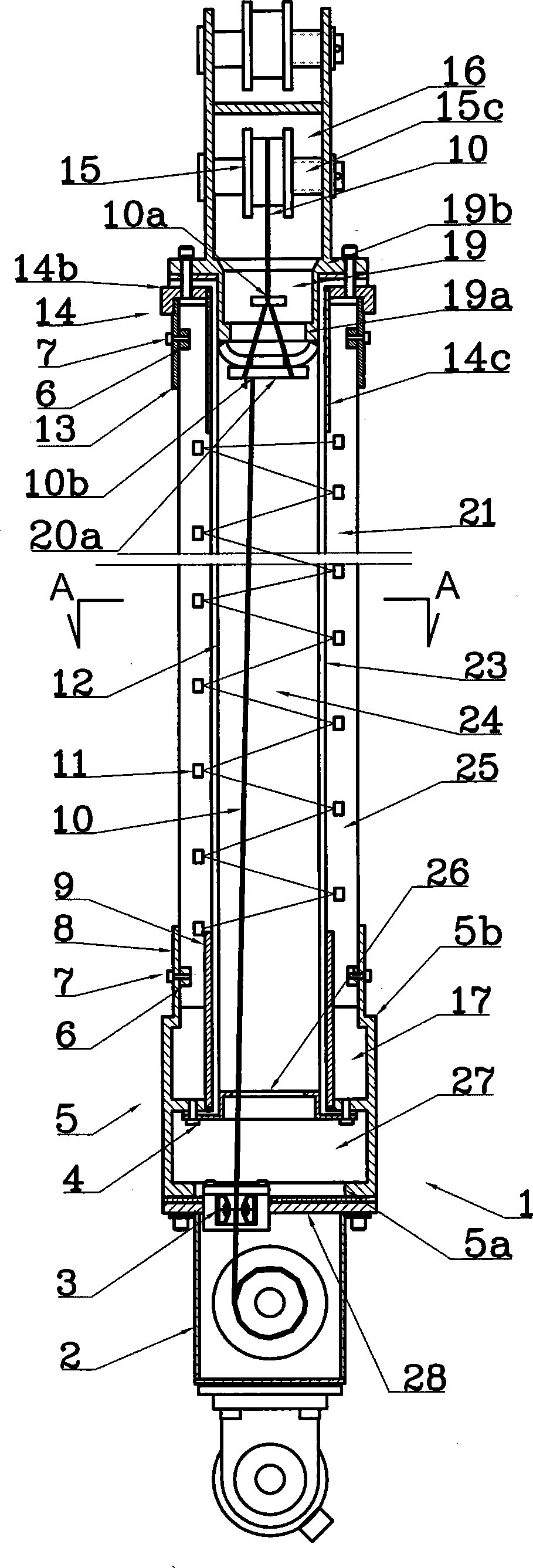

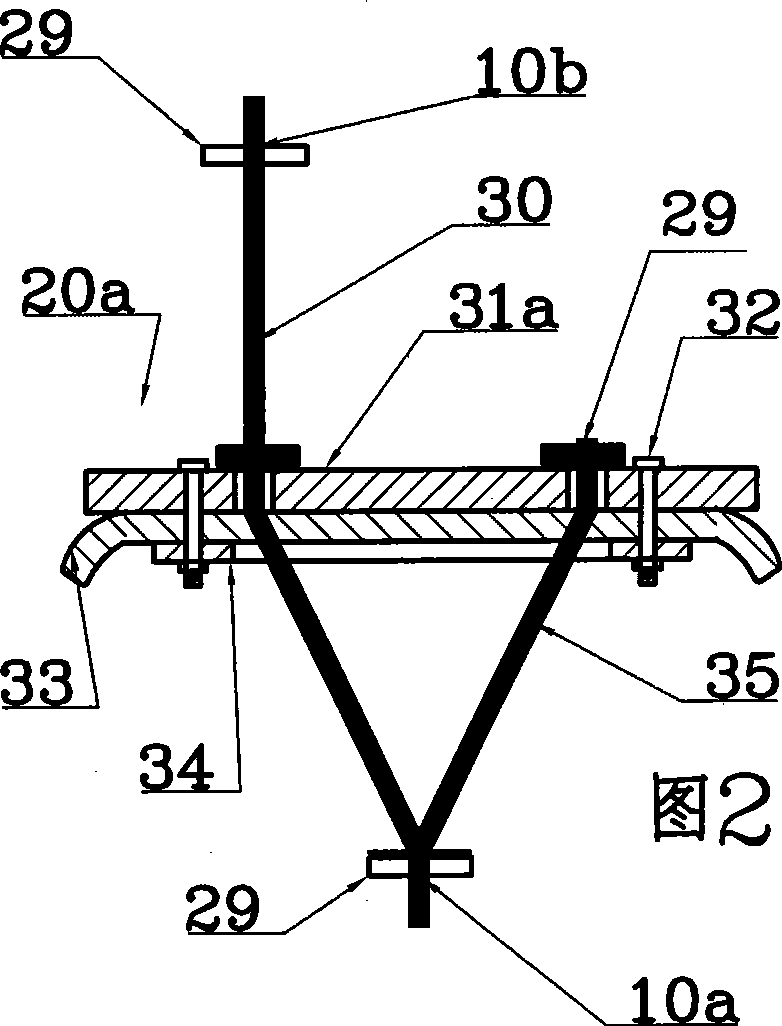

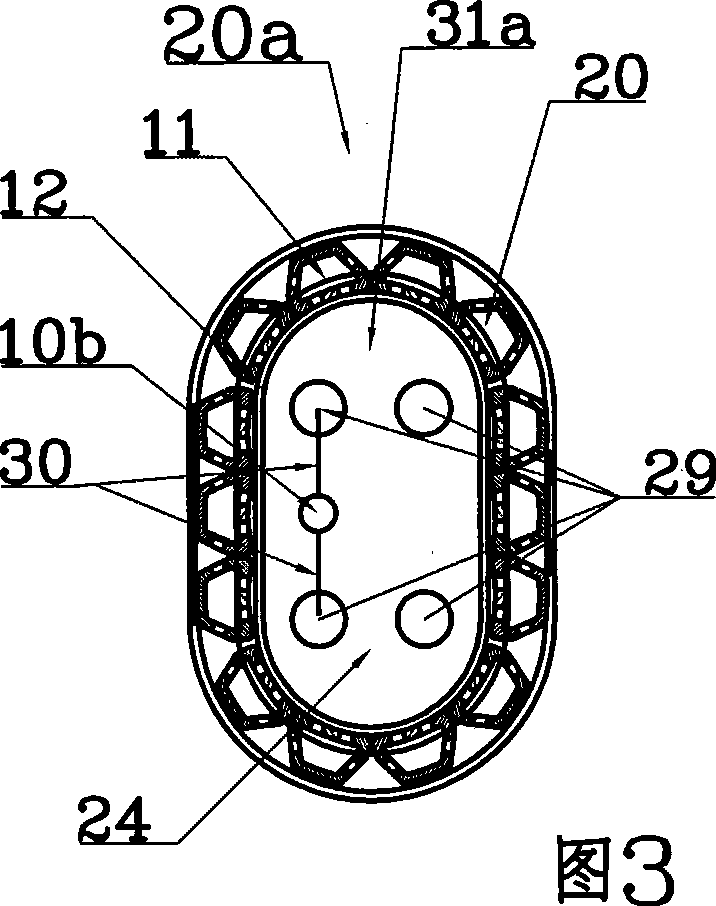

[0052] All membrane units 1 of the invention in the present embodiment are arranged side by side between the upper flange chamber 14 and the lower flange chamber 5; membrane unit 1 comprises the following elements of flexibility: tubular filter membrane 12 and tubular grid 21, at least one The long-axis center line of the tubular filter membrane 12 of layer and tubular grid 21 coincides, and is vertical with horizontal line; Form circular slurry chamber 24 in tubular filter membrane 12, tubular grid 21 is set outside tubular filter membrane 12; The upper flange chamber 14 provided on the upper part of the membrane module is provided with a connecting channel 16 and a discharge branch pipe 14c, and the other end of the filter slurry chamber 24 of each membrane unit 1 on the membrane module is aligned with each other and is perpendicular to the discharge through the connecting channel 16. The branch pipe 14c is connected, and the connecting channel 16 of the membrane unit is prov...

Embodiment 2

[0057] In Fig. 4, 5, 6 and 10, embodiment 2 of the membrane assembly of the present invention is shown, and the difference between this embodiment and embodiment 1 is: a tubular sealing membrane 36 is set outside the tubular grid of the membrane unit, and the tubular sealing The membrane 36 covers the tubular frame 21 from the outside, and forms an annular filtrate collection chamber 36b between the tubular sealing membrane 36 and the tubular filter membrane 12. The upper end of the tubular sealing membrane 36 is connected and sealed to the lower end surface 14a of the upper flange chamber 14 The lower end of the branch pipe 13 and the tubular sealing membrane 36 is connected and sealed to the branch pipe 8 on the upper end surface of the lower flange chamber 5, and the annular filtrate collection chamber 36b communicates with the respective horizontal filtrate collection chamber 17.

[0058]The tubular closure membrane 36 is a thin-walled tube that is flexible and leak-free; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com