Separator for coal mill

A separator and coal mill technology, applied in the field of separators, can solve the problems of inconspicuous adjustment of coal fineness, uneven coal particles, and low efficiency of powder selection, so as to improve the efficiency and accuracy of powder selection , The effect of uniform pulverized coal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

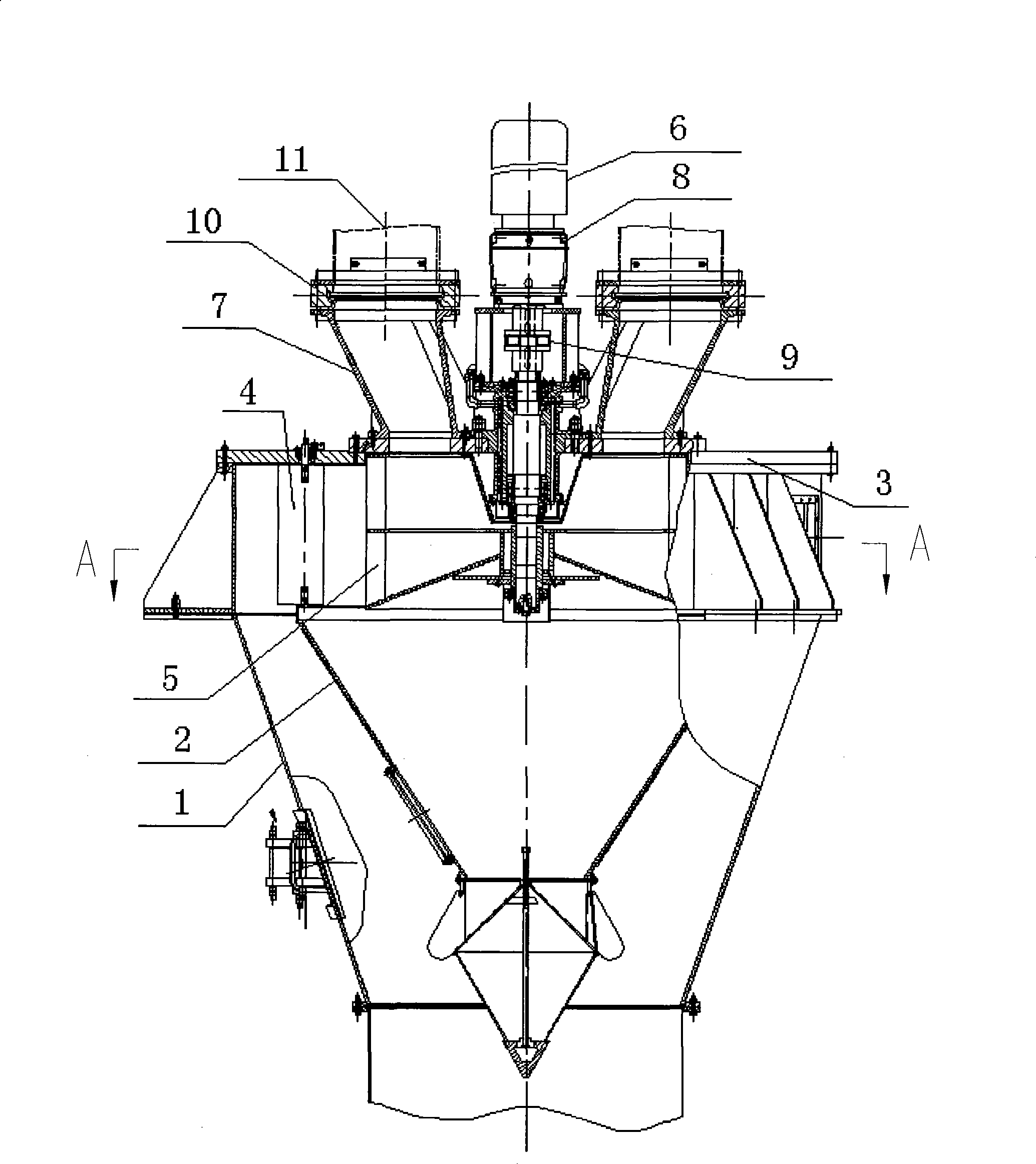

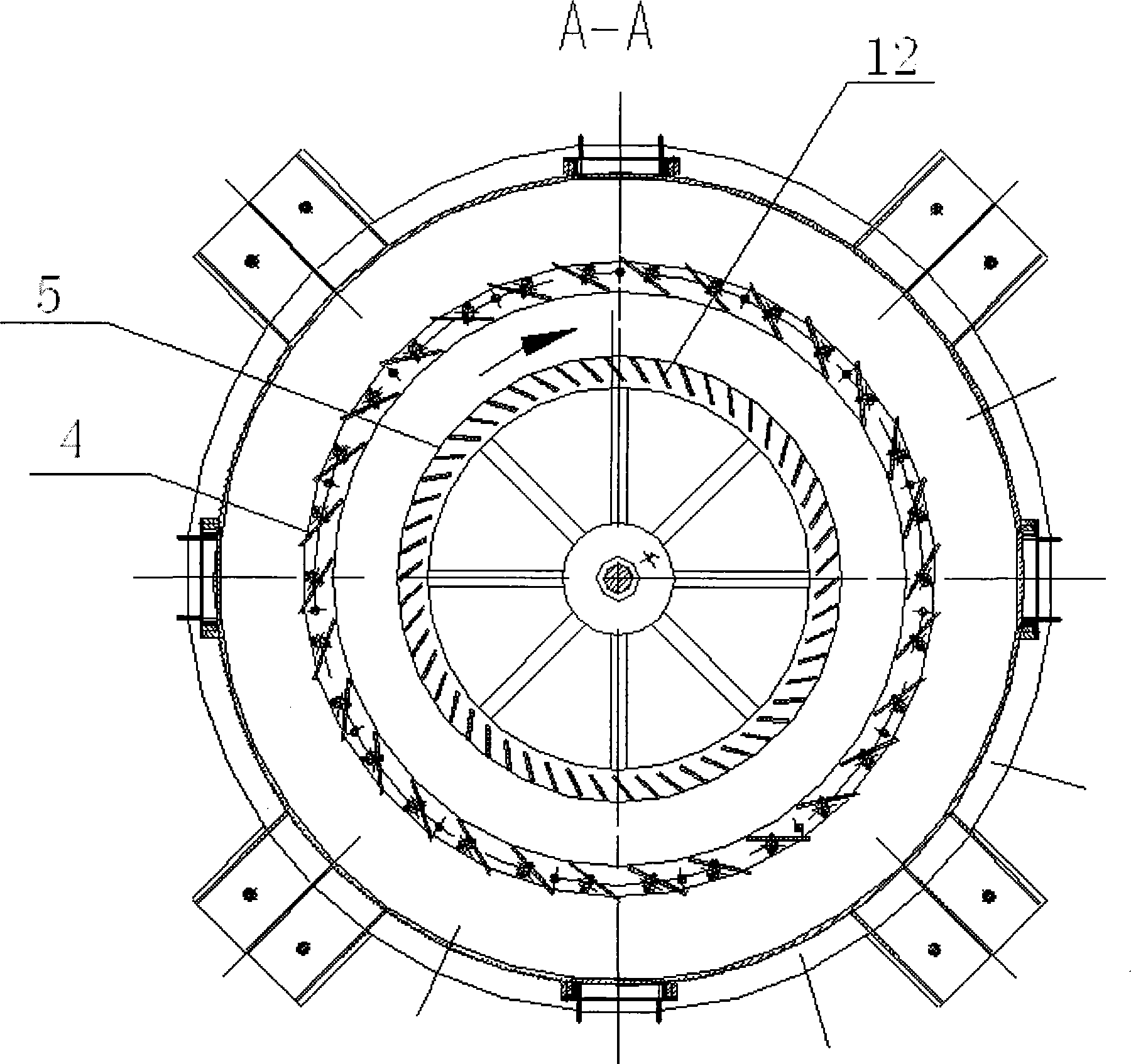

[0011] The structure of the coal mill separator of the present invention can be referred to figure 1 As shown, it includes a motor 6, an inner cone 2, an outer cone 1 and a cover 3, the cone ends of the inner cone 2 and the outer cone 1 face downward, and the inner cone 2 is placed in the In the outer cone 1, the cover body 3 is covered on the outer cone body 1, and a static vane 4 is arranged between the upper edge of the inner cone body 2 and the cover body 3, and the static vane 4 Longitudinally arranged and arranged in a circle along the upper edge of the inner cone 2, a rotating impeller 5 is arranged inside the static blades 4 arranged in a circle, and the rotating impeller 5 is driven by the motor 6. The axes of the rotating impeller 5 , the inner cone 2 and the outer cone 1 coincide, and a discharge port 7 is arranged above the rotating impeller 5 .

[0012] The rotary impeller 5 is connected with the motor 6 through a speed reducer 8 . The speed reducer 8 is also co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com