Flexible fuel engine control system and control method

An engine controller, flexible fuel technology, applied in engine control, combustion engine, internal combustion piston engine, etc., can solve the problems of high cost, reduced overall engine performance, long cycle and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings.

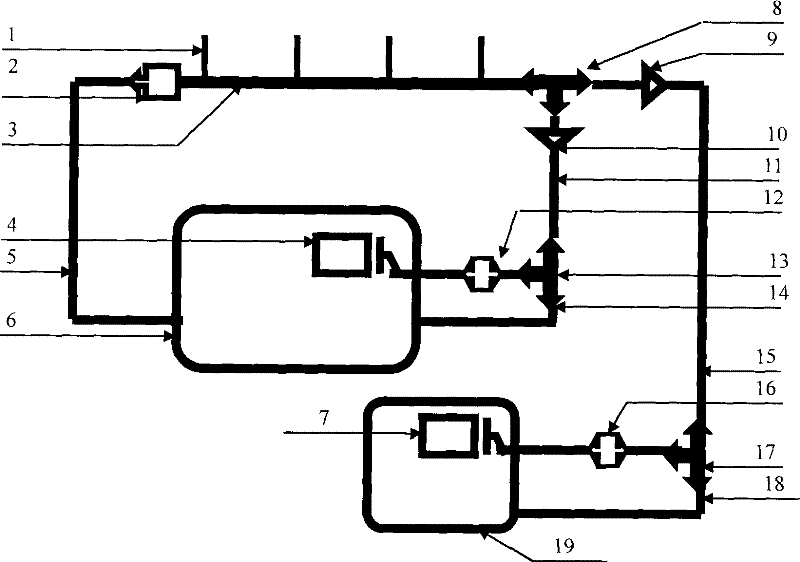

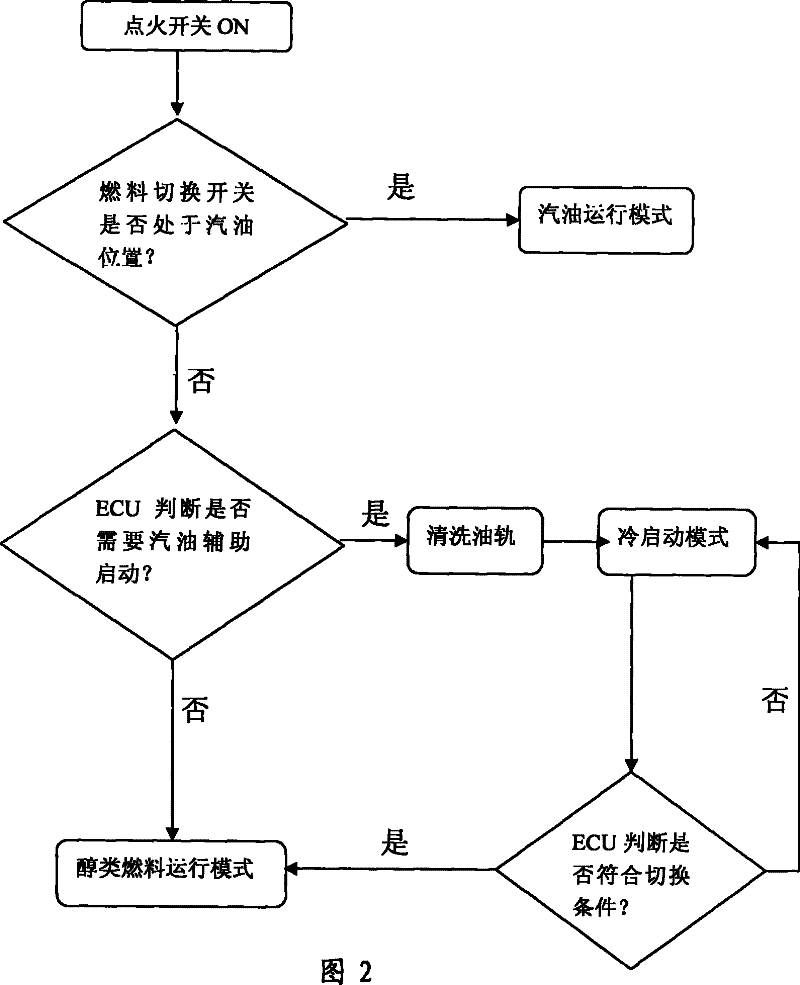

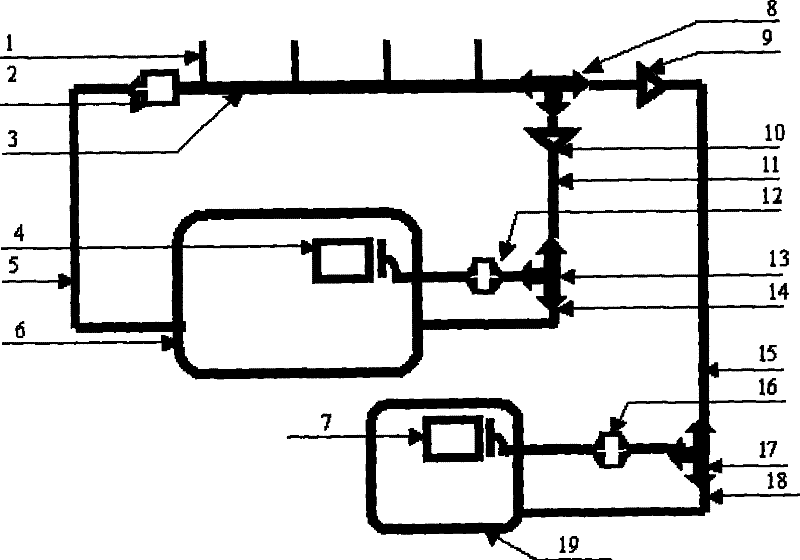

[0018] like figure 1 As shown, the system adds a set of auxiliary fuel supply system and a set of cleaning system on the basis of the fuel injector 1, fuel rail 4 and main fuel supply system included in the original engine fuel injector system, among which the auxiliary fuel supply system For cold starts, the purge system is used to purge alcohol fuel from the fuel rail into the main tank during low temperature cold starts. By making changes to the injector material, the same set of injectors can be utilized for start-up and normal operation.

[0019] The main oil supply system mainly includes the main oil tank 6, the main oil pump 4, etc.; the auxiliary oil supply system mainly includes the auxiliary oil tank 19, the auxiliary oil pump 7, etc. There are three-way valves and one-way valves in the main oil supply system and the auxiliary oil supply system oil circuit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com