Electronic component

A technology of electronic components and terminals, which can be applied to computer parts, record carriers used by machines, instruments, etc., and can solve problems such as insufficient joint strength and insufficient reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

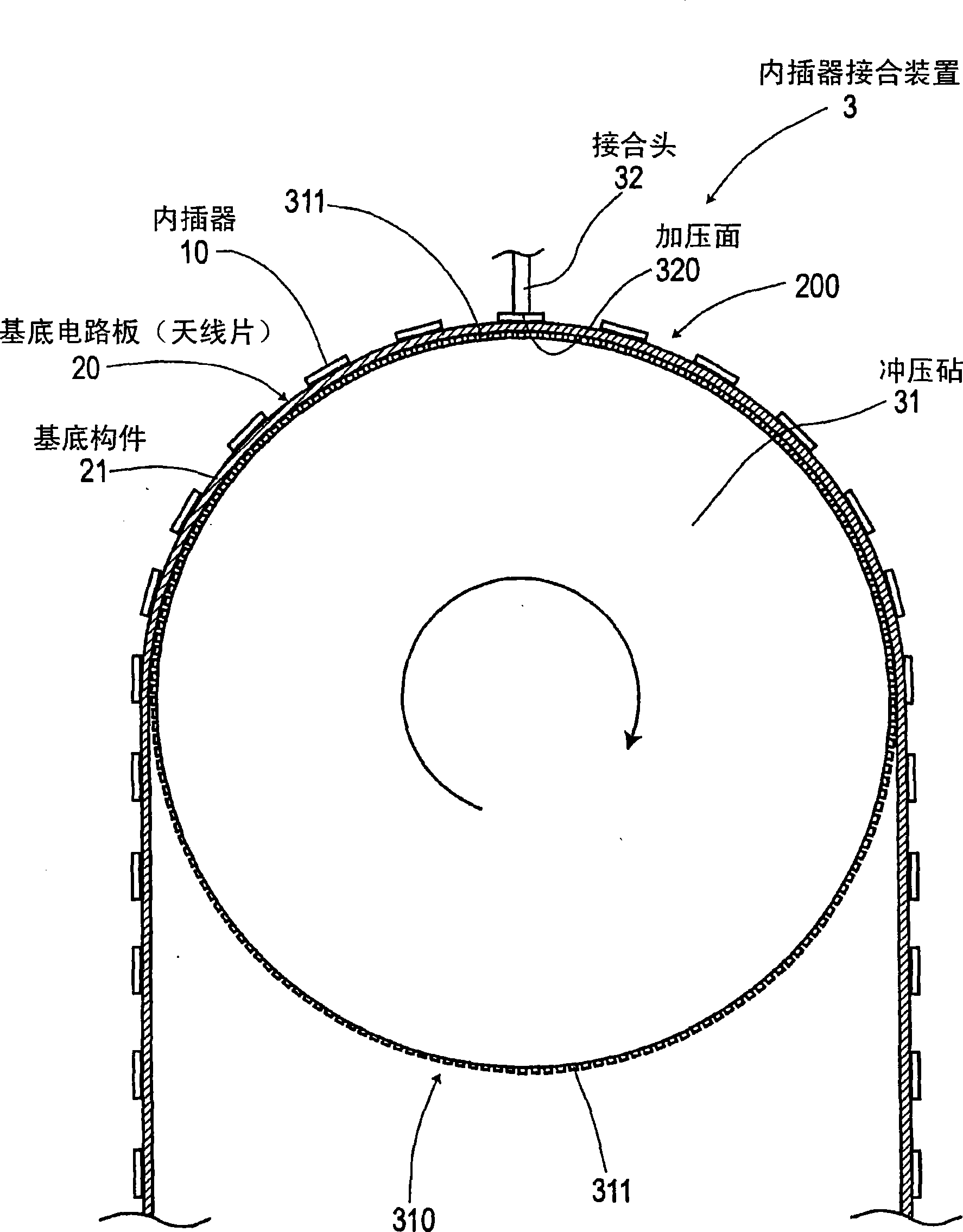

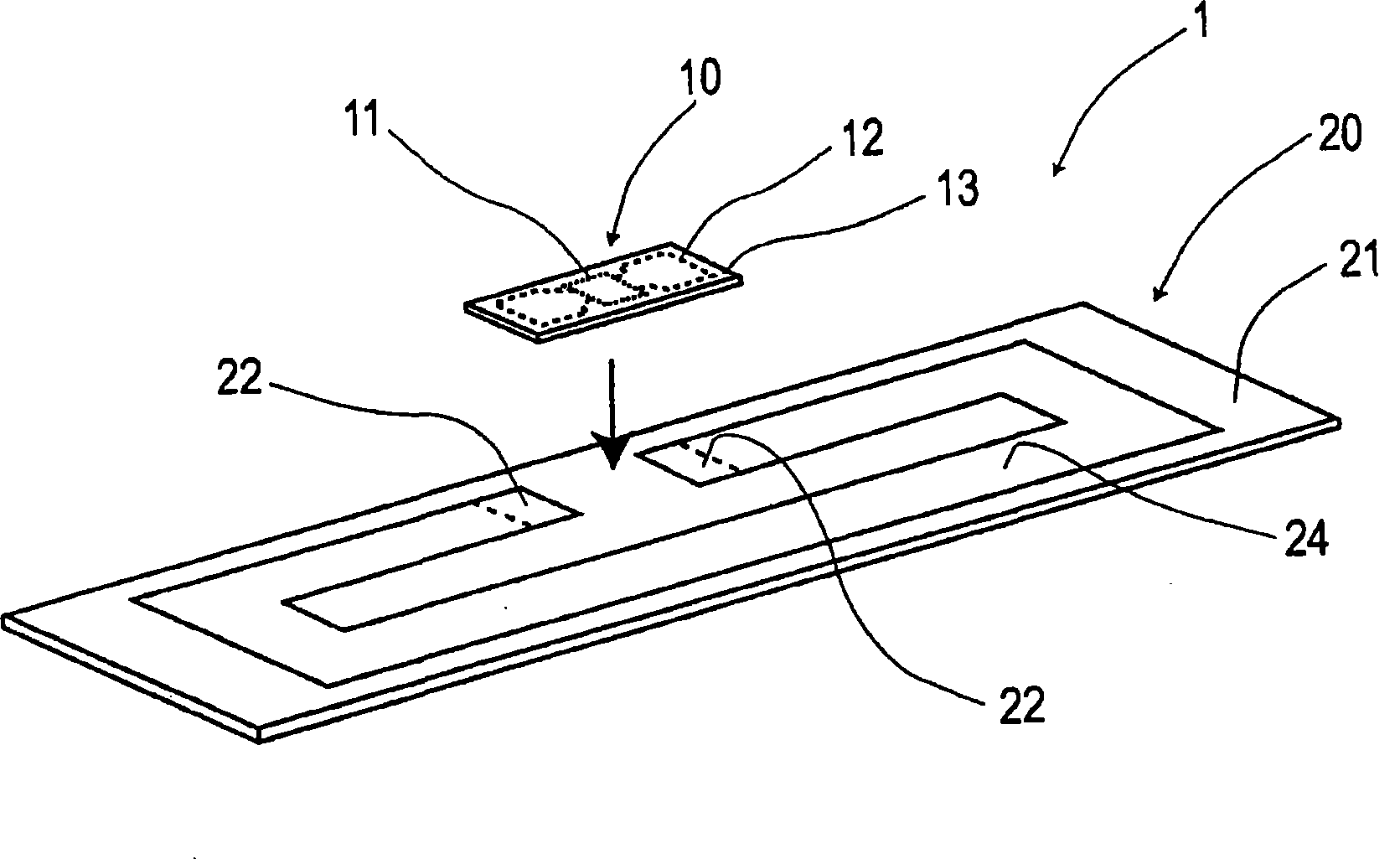

[0065] This example relates to an electronic component 1 in which an interposer 10 and a base circuit board 20 are bonded, and an interposer bonding apparatus 3 for manufacturing the electronic component 1 . refer to Figure 1 to Figure 9 Describe the content.

[0066] The interposer joint device 3 of this example is as figure 1 with figure 2 Shown is an interposer 10 configured for mounting a semiconductor chip 11 on a plate-shaped chip holding member 13 and having an interposer-side terminal 12 as a connection terminal extending from the semiconductor chip 11. A device that is bonded to a base circuit board 20 composed of a plate-shaped base member 21 and provided with base-side terminals 22 on its surface.

[0067] This interposer bonding device 3 has: a stamping anvil 31 that holds the base circuit board 20 on which the interposer 10 is stacked in a state where the interposer-side terminal 12 and the base-side terminal 22 face each other; The stamping anvil 31 perform...

Embodiment 2

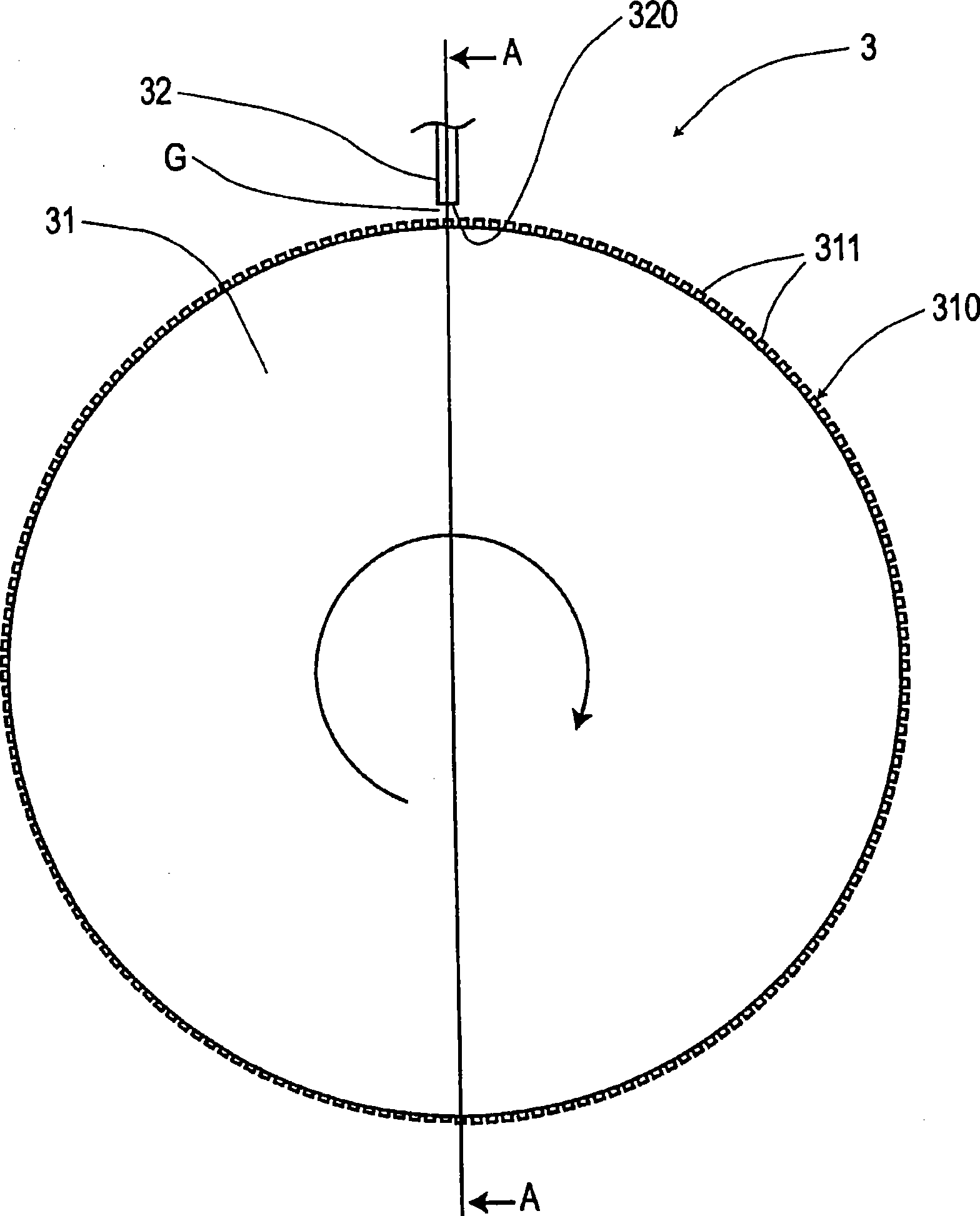

[0101] This example is based on the interposer joining device 3 of the first example, and mainly changes the shapes of the pressing surface 320 of the joining head 32 and the convex forming portion 310 of the press anvil 31 . refer to Figure 11 to Figure 16 Describe the content.

[0102] In the interposer joint device 3 of this example, as Figure 11 As shown, the bonding head 32 is in contact with the antenna board 20 , and the stamping anvil 31 is in contact with the interposer 10 .

[0103] The bonding head 32 of this example is as Figure 11 and Figure 12 As shown, there is a pressing surface 320 formed in a curved concave shape corresponding to the curved outer peripheral surface of the press anvil 31 . The pressing surface 320 is wider than the interposer 10 in the circumferential direction of the press anvil 31 . Therefore, in the interposer joining device 3 of this example, the entire surface of the interposer-side terminal 12 can be simultaneously pressurized by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com