Field emission light source

A technology of field emission and light source, applied in the field of light source, can solve the problem of low luminous efficiency of field emission light source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

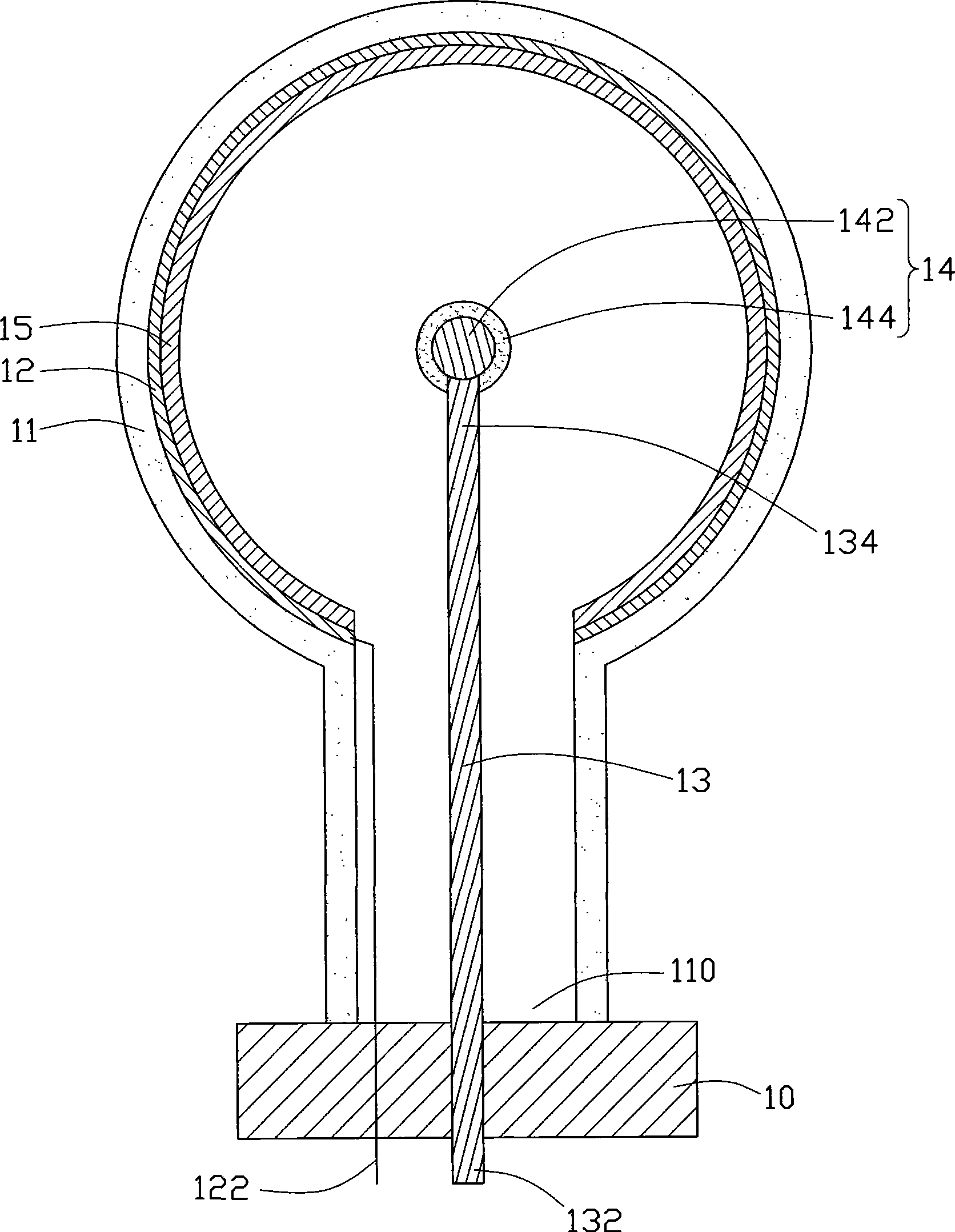

[0011] refer to figure 1 , The field emission light source 100 of the first embodiment of the technical solution includes a base 10 , a casing 11 , an anode 12 , a support 13 , and a cathode 14 .

[0012] The base 10 is made of insulating materials, such as glass, ceramics and the like. One end of the casing 11 has an opening 110 , and one end of the casing 11 having the opening 110 is installed on the base 10 so that the casing 11 and the base 10 jointly define a closed receiving space. The housing 11 can be made of transparent insulating material, such as glass or transparent ceramics. The casing 11 can be spherical, ellipsoidal or pear-shaped, and the casing 11 is pear-shaped in this embodiment.

[0013] The anode 12 is a layer of transparent conductive film such as indium tin oxide film or aluminum film. In this embodiment, the anode 12 is a transparent indium tin oxide film. The anode 12 is formed on the inner wall of the casing 11 . The wire 122 passes through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com