Laser welding method

A laser welding and laser beam technology, applied in laser welding equipment, welding equipment, household components, etc., can solve the problems of lack of flexibility, no laser welding application, etc., and achieve the effect of uniform measurement error, easy quality and high welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

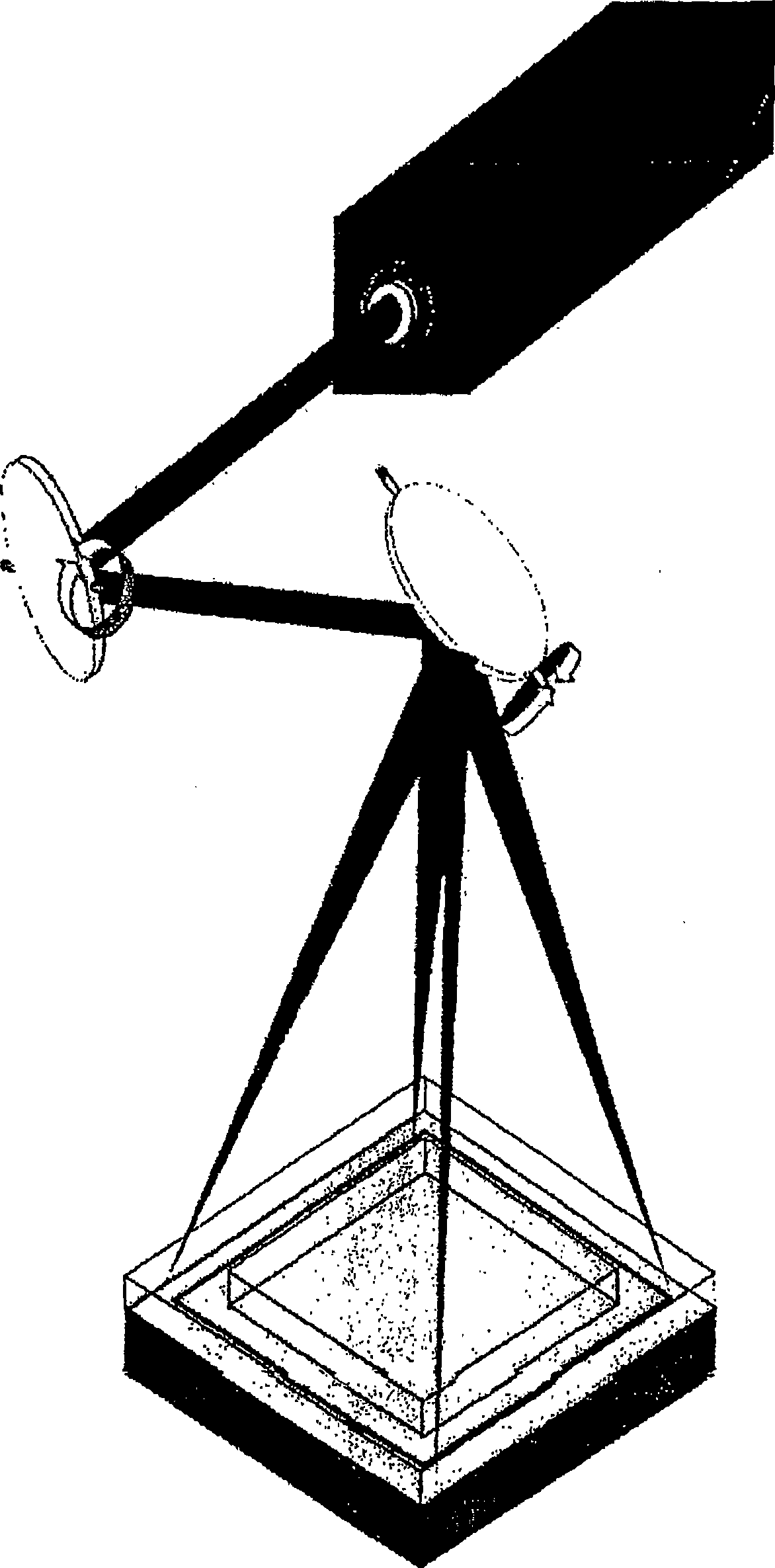

[0034] The method of the invention uses a scanner known from laser marking in plastic welding ( figure 1 )carry out testing. In this technique, a laser beam is scanned at high speed over the welding site by means of a metal fume thermal mirror. Due to the low thermal conductivity of plastics, the weld joint to be formed becomes progressively hotter and relatively uniform so that the entire weld joint melts almost simultaneously. In this method, the welding time is determined by the welding rate, ie the scan rate employed, the number of welding cycles employed and the size of the workpiece. The weld path forming the weld joint may be formed based on, for example, a CAD image.

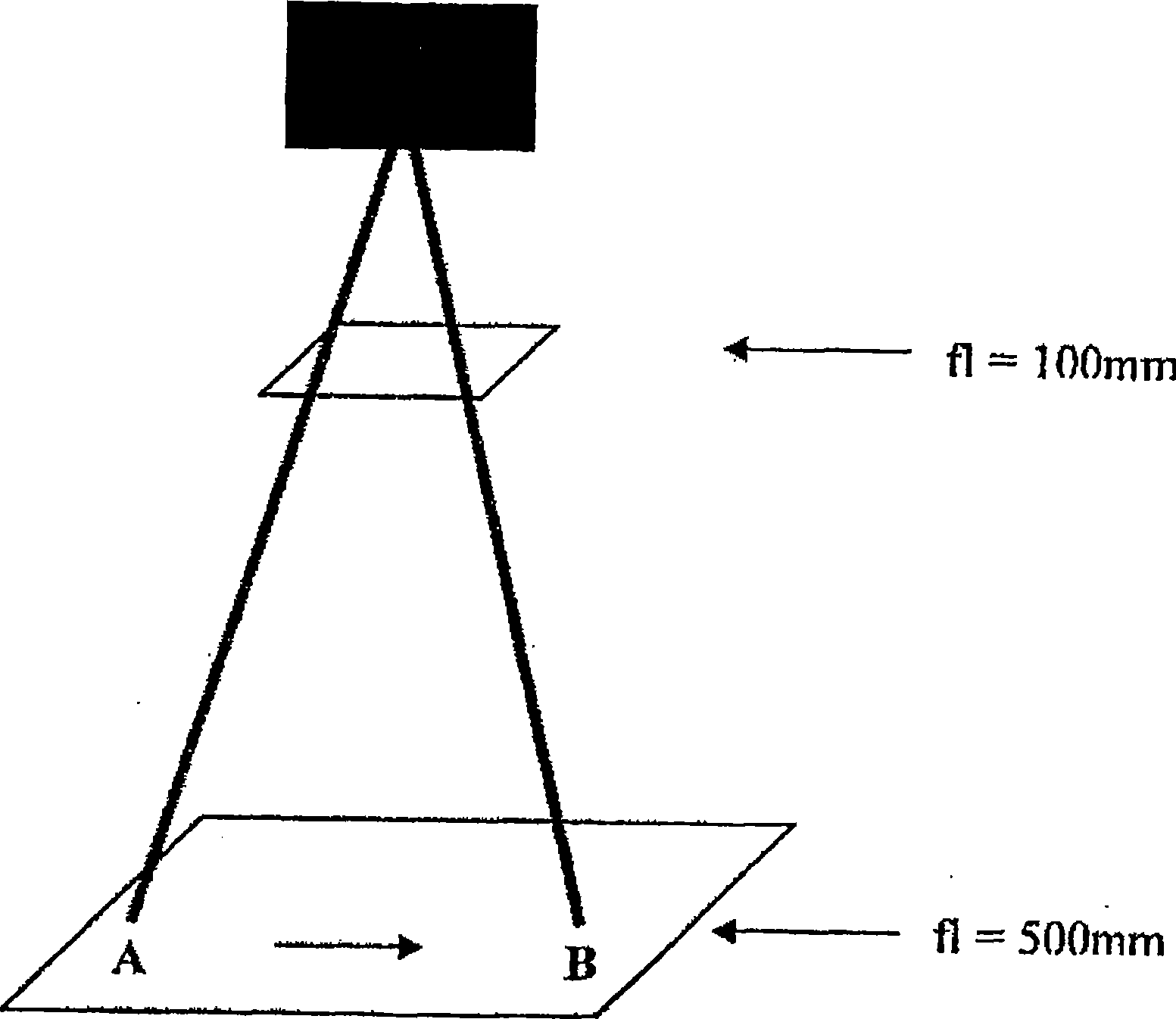

[0035] The speed and working area of the scanner used in scanning welding are determined by the lens used. For example, in one test a known diode laser device used achieved a working area of 100 mm x 100 mm in which the size of the focus, ie the width of the weld, was 1.1 mm when a focal length of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com