Washing machine laundry drum

A technology for washing tubs and washing machines, applied in the field of washing tubs, which can solve problems such as expensive and expensive wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

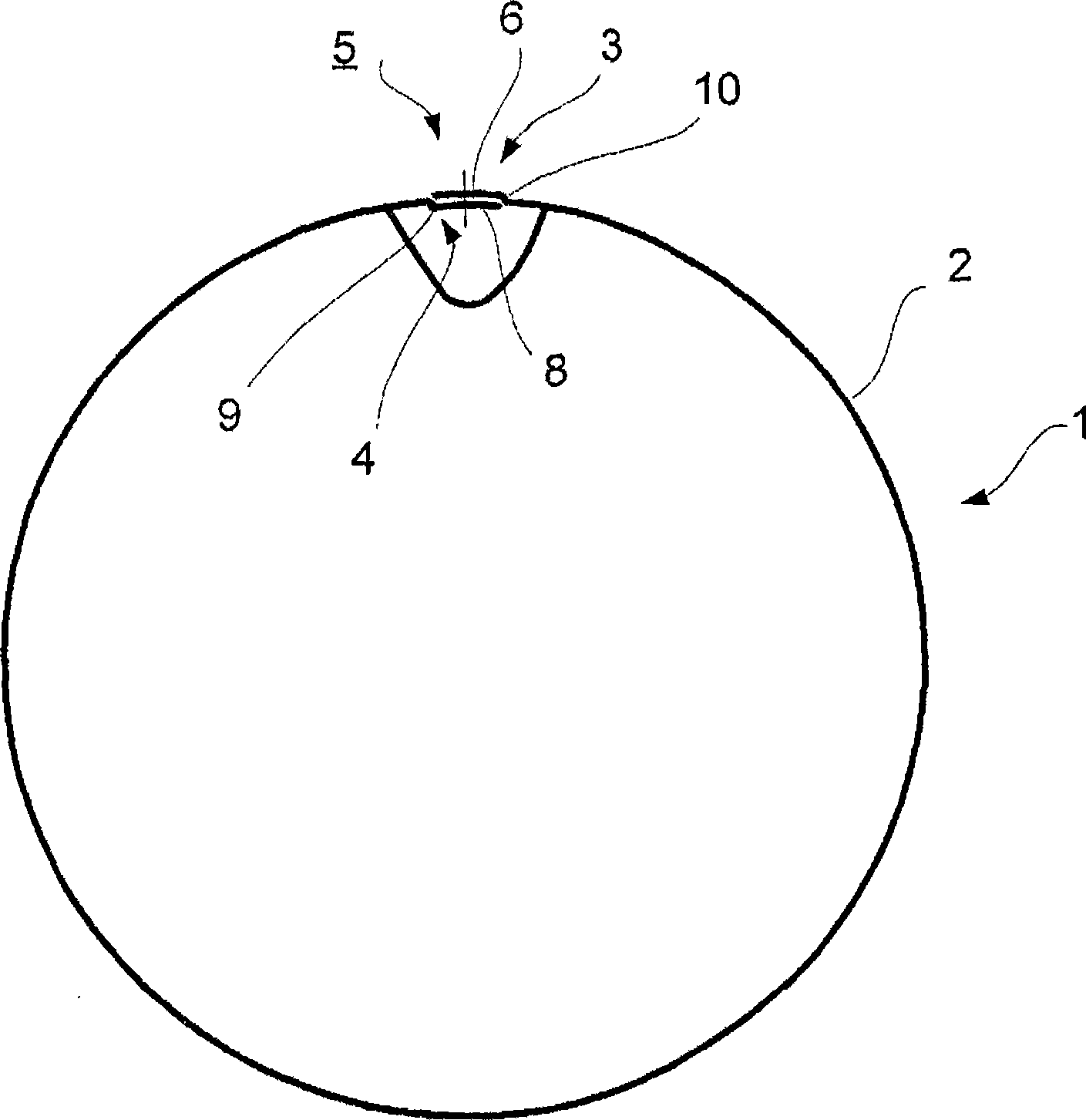

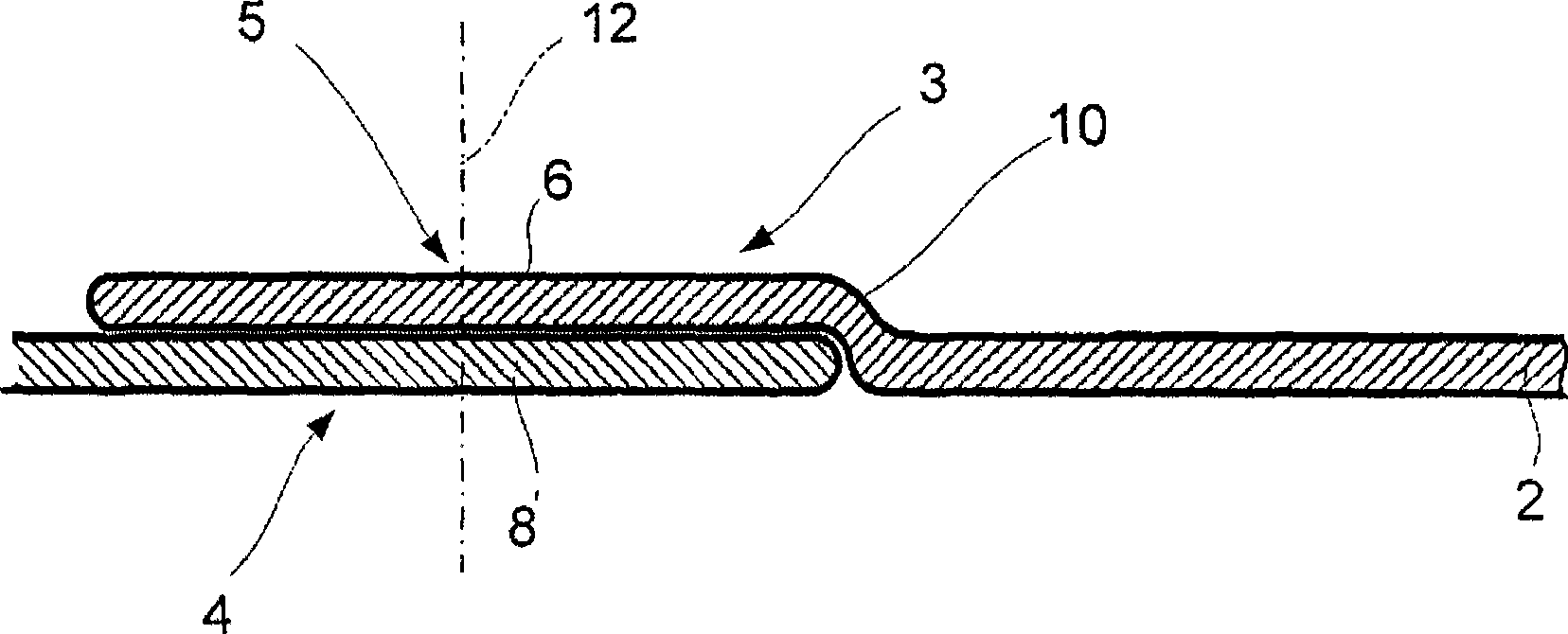

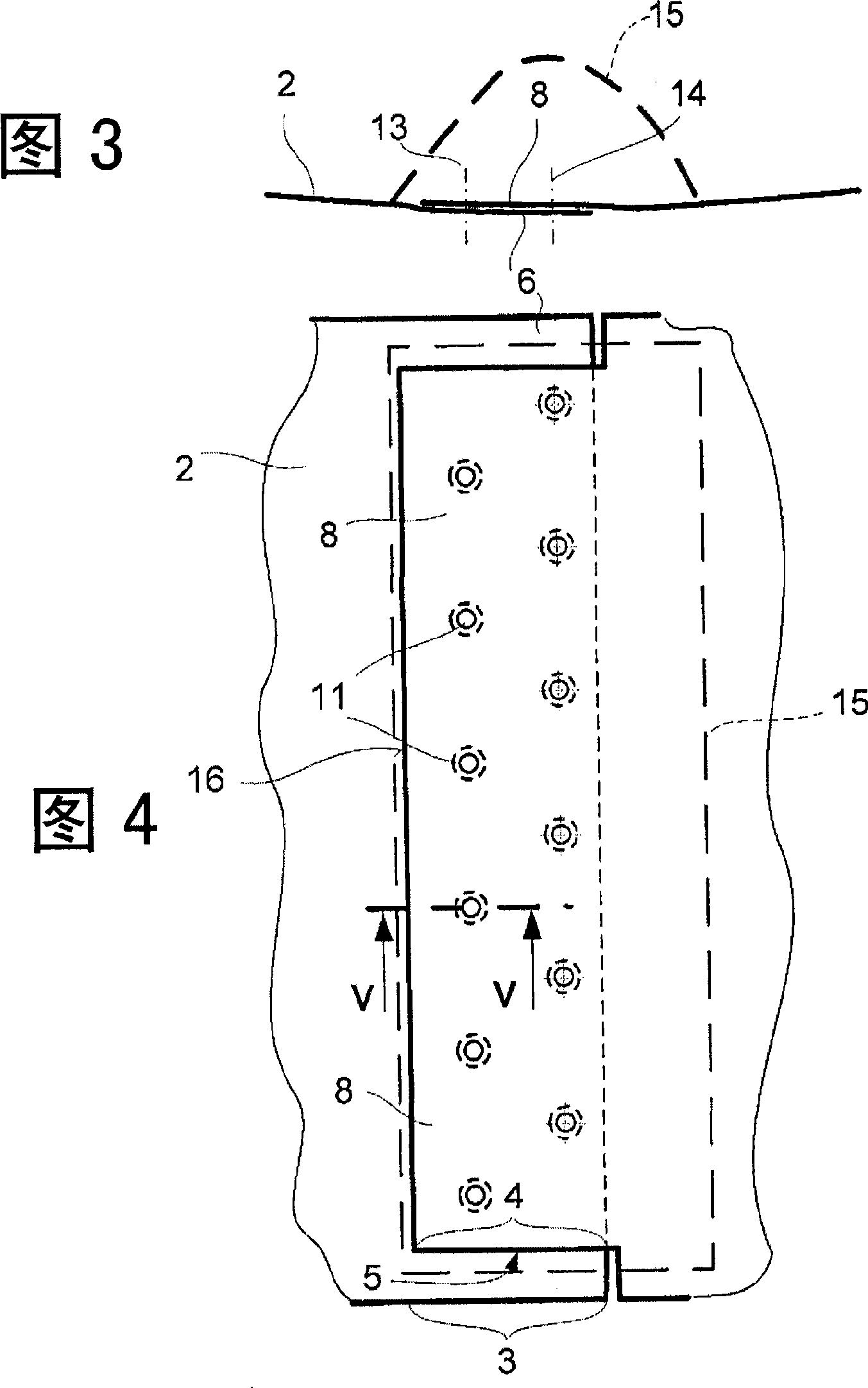

[0020] exist figure 1 The washing drum 1 described in has a rotating drum shell 2 which is bent into a drum body from a strip of thin-walled material. The material is traditionally high grade steel plate. The end edges 3 and 4 of the bent cylinder are connected to the connecting seam 5 (at figure 2 ), the connecting seam has lapping strips 6 and 8 which are arranged one above the other, wherein the upper lapping strip 6 reaches the fold line 9 of the bottom lapping strip 8 , and the lower side lapping strip 8 reaches the folding line 10 of the upper side lapping strip 6 .

[0021] According to the present invention, figure 2 The connecting seam 5 in is formed by means of two overlapping strips 6 and 8 of the cartridge shell 2 arranged one above the other and provided in the ends 3 and 4 . The straps 6 and 8 may be connected to each other in any manner, for example by a row of rivets (not shown) along the central axis 12 . The connecting seam can also be provided as a we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com