Eutectic graphite gray cast iron continuous casting profile and manufacturing method thereof

A technology of gray cast iron and profiles, applied in the field of casting, can solve problems such as the uniformity of cross-sectional hardness, unstable drawing state, and low tensile strength, so as to improve oil and gas leakage resistance, tensile strength and cross-section The uniformity of hardness is improved and the effect of uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] The preparation technology of profile of the present invention is as follows:

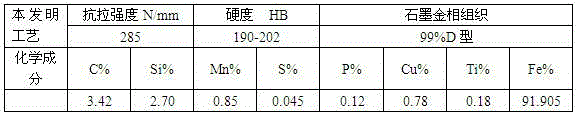

[0015] Smelting process: dual smelting with power frequency induction furnace and cupola. The raw iron is smelted by fast thermal analyzer and spectrum control in front of the furnace and adjusted in time. 75% ferrosilicon inoculant, the particle size of the inoculant is 0.5mm, the amount of inoculant added is 0.6% of the molten iron mass, and the carbon equivalent of the molten iron after inoculation is controlled at 4.32; molten iron spectral analysis: determine C, Si, Mn, P, S, Ti Content, according to the cross section of the profile and the performance requirements, adjust the carbon equivalent and C, Si, Mn, P, S, Ti, the appropriate amount according to the mechanical properties of the profile and the matrix structure. The amount of each raw material is shown in Table 3.

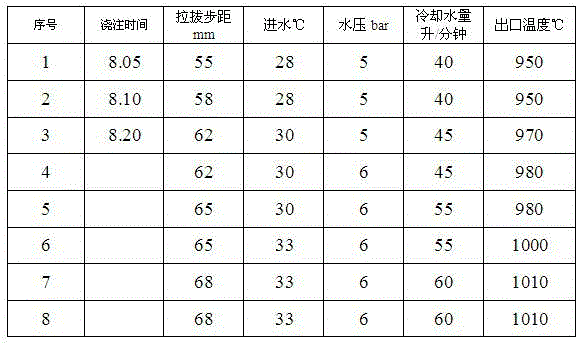

[0016] The continuous casting profile drawing process is carried out, and the continuous casting profile is manufa...

Embodiment 2

[0024] The preparation technology of profile of the present invention is as follows:

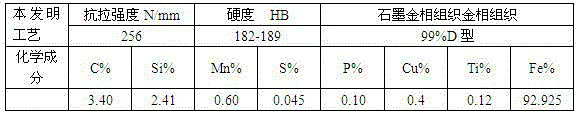

[0025] Smelting process: dual smelting with power frequency induction furnace and cupola, the content of the original molten iron is controlled by rapid thermal analyzer and spectrum in front of the furnace and adjusted in time. Ordinary 75% ferrosilicon inoculant, the particle size of the inoculant is 12mm, the amount of inoculant added is 1.0% of the mass of molten iron, and the carbon equivalent of molten iron after inoculation is controlled at 4.38;

[0026] Spectral analysis of molten iron: determination of C, Si, Mn, P, S, Ti content,

[0027] According to the cross-section and service performance requirements of the profile, adjust the carbon equivalent and the appropriate amount of C, Si, Mn, P, S, Ti based on the mechanical properties of the profile and the matrix structure. The amount of each raw material is shown in Table 4.

[0028] The continuous casting profile drawing process...

Embodiment 3

[0033] The preparation technology of profile of the present invention is as follows:

[0034] Smelting process: dual smelting with power frequency induction furnace and cupola, the content of the original molten iron is controlled by rapid thermal analyzer and spectrum in front of the furnace and adjusted in time. Ordinary 75% ferrosilicon inoculant, the particle size of the inoculant is 0.5mm, the amount of inoculant added is 0.7% of the mass of molten iron, and the carbon equivalent of molten iron after inoculation is controlled at 4.20;

[0035] Spectral analysis of molten iron: determination of C, Si, Mn, P, S, Ti content,

[0036] According to the cross-section and performance requirements of the profile, adjust the carbon equivalent and the appropriate amount of C, Si, Mn, P, S, Ti based on the mechanical properties of the profile and the matrix structure. The amount of each raw material is shown in Table 5.

[0037] The continuous casting profile drawing process is car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com