Tripping connecting rod and production process thereof

A tripping link and production process technology, which is applied to high-voltage air circuit breakers, air switch components, electrical components, etc., can solve the problems of insufficient strength and fracture of the tripping link, avoid cooling shrinkage deformation, and improve bonding The effect of strength and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

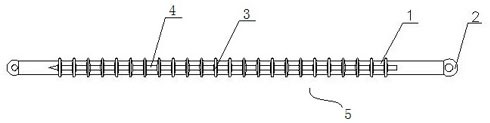

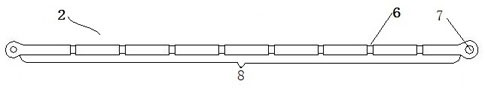

[0040] Such as figure 1 As shown, the trip link 5 is composed of a core rod body 2 and an insulating cladding 1 , and the insulating cladding 1 is wrapped on the outer peripheral surface of the core rod body 2 . Specifically, the insulating cladding 1 is fixedly connected to the outer peripheral surface of the core rod body 2 through a pressing process. In this embodiment, the core rod body 2 is made of laminated glass cloth board, which not only has high tensile strength, but also avoids shrinkage and deformation when cooling down, thus ensuring that the core rod body 2 and the insulating cladding 1 The shape and position tolerance in the pressing and forming process; the insulation cladding 1 is made of unsaturated polyester fiberglass molding compound material, which has good insulation performance and high temperature fluidity, so as to ensure the detachment The insulation requirements of the buckle connecting rod are convenient for it to be effectively wrapped on the out...

Embodiment 2

Embodiment 3

[0043] Embodiment 3 of the tripping rod of the present invention is different from Embodiment 1 in that the material of the core rod body is nylon, and only the tensile strength of the core rod body made of nylon material can meet the resistance of the tripping rod. Tensile strength requirements. Certainly, in other embodiments, the material of the core rod body may also be metal, and in this case, the surface of the core rod body needs to be fully covered with an insulating cladding.

[0044] Embodiment 4 of the tripping rod of the present invention is different from Embodiment 1 in that the insulating cladding is made of nylon, and at this time the insulating cladding is wrapped on the outer peripheral surface of the core rod by injection molding. Certainly, in other embodiments, the material of the insulating cladding can also be epoxy resin, and in this case, the insulating cladding is wrapped on the outer peripheral surface of the core rod body through an injection proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com