Method for vertically extruding a concrete element, device for producing a concrete element and wind turbine generator tower produced by this method

A vertical extrusion, concrete technology, applied to wind turbines, wind turbine components, and configurations for installing/supporting wind turbines in the same direction as the wind, which can solve problems such as large logistical support, high electricity prices, and consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The name extrusion is used below, although it is not commonly used in the field of concrete construction. Typically when extruding plastic or other hardenable viscous materials extrusion is done in a continuous process through a nozzle. For this purpose this material—the extrudate—is melted and homogenized by means of heating. Build up the required pressure while flowing through the nozzle. The material solidifies after being discharged from the nozzle. The cross-section of the geometry thus produced corresponds to the nozzle used or to the hole pattern arranged behind it.

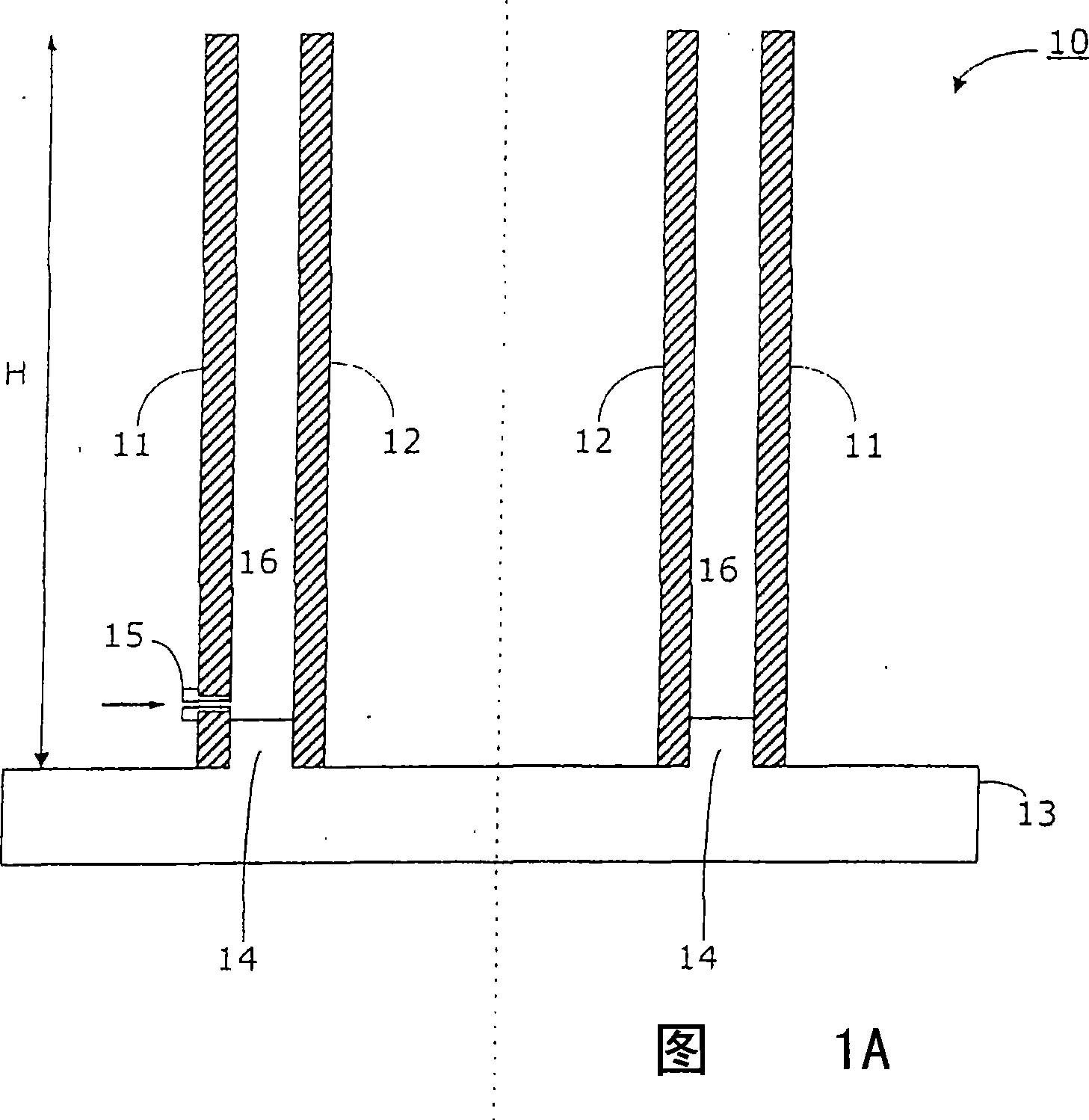

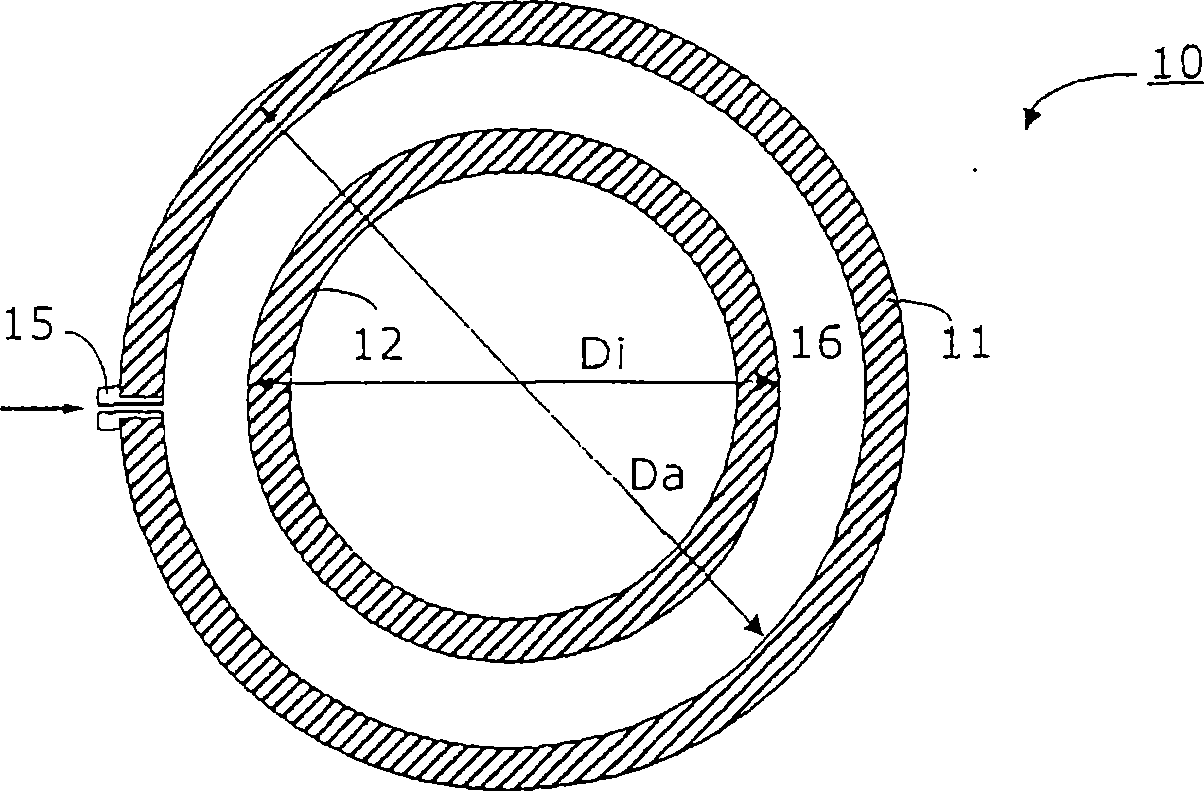

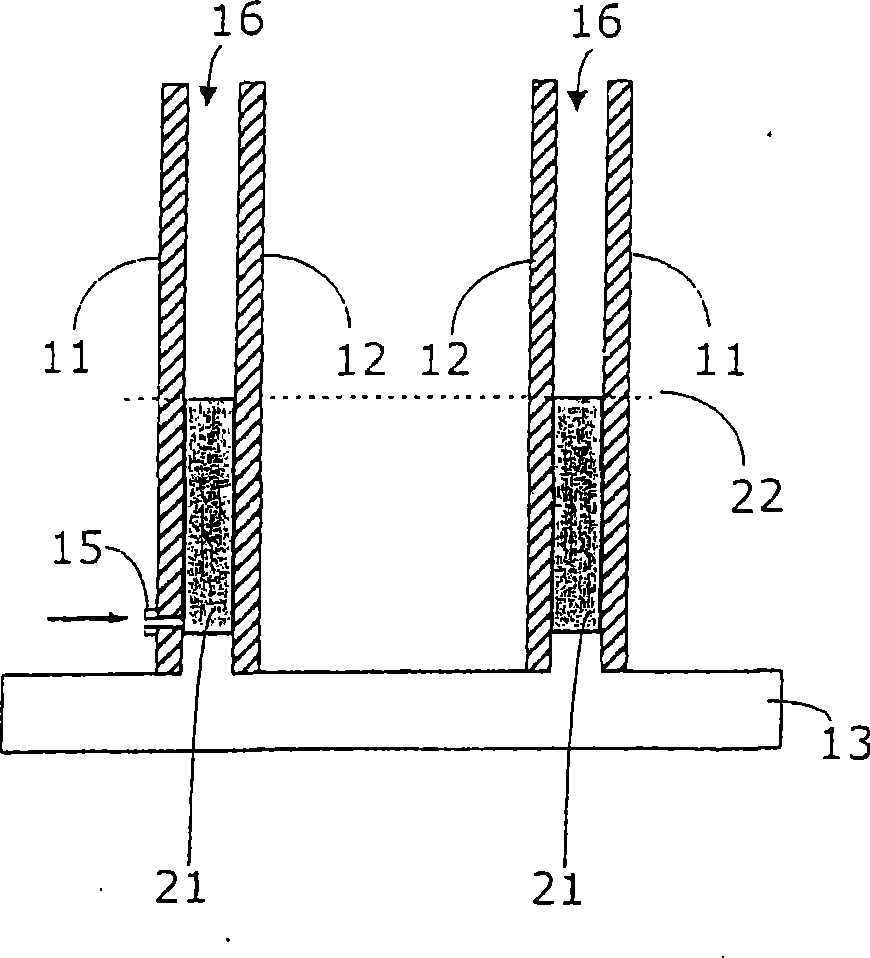

[0061] The invention relates to the fabrication in situ of longitudinal concrete elements 20 extending in the vertical direction. The invention is particularly suitable for the manufacture of towers (eg wind power plants), columns, electrical towers and piers (eg of bridges or drilling platforms). Such concrete elements are constructed on site, that is to say directly at a defined location (loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com