Novel copper and copper alloy plate belt electromagnetism assistant casting method and device

A copper alloy plate and electromagnetic technology, which is applied in the field of non-ferrous metal processing, can solve problems that do not involve the preparation process and equipment of copper and copper alloy slabs, achieve simplified homogenization process, improve the yield of strip processing, and improve the surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

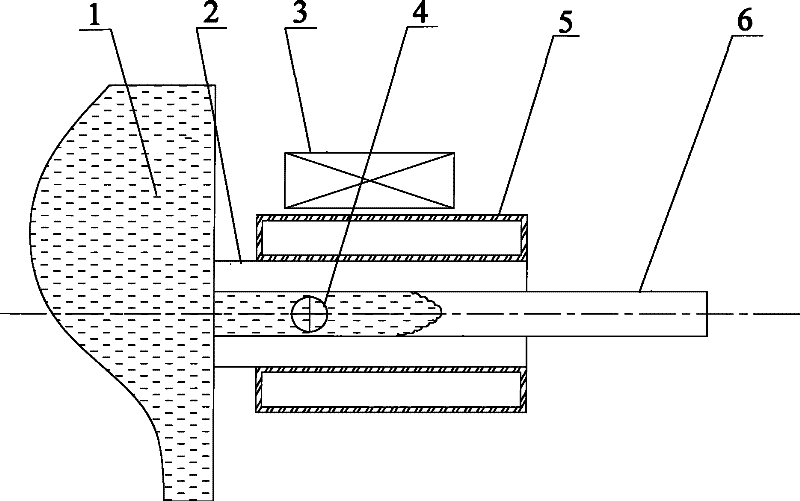

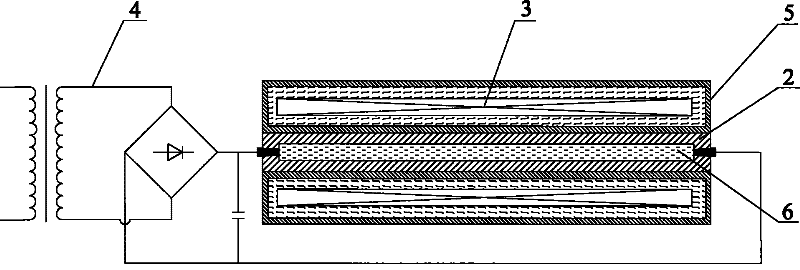

[0026] The magnetic field generating device 3 is fixed inside the metal water-cooled crystallizer 5, such as figure 2 , the graphite crystallizer 2 and the metal water-cooled crystallizer 5 are installed on the horizontal continuous casting furnace group 1. When the copper alloy liquid in the horizontal continuous casting furnace group 1 reaches 1000-1200 ° C, the tractor is started to start continuous casting, driving the copper The alloy slab 6 moves, one electrode of the DC power supply 4 is electrically connected to one side wall on the lateral side of the graphite crystallizer 2, and the other electrode of the DC power supply 4 is electrically connected to the other side wall on the lateral side of the graphite crystallizer 2 Through, a current loop is formed between the two side walls of the graphite crystallizer lateral side, and the current intensity is 50-500 amperes; the magnetic field generator 3 generates a magnetic field of 150-1000 gauss, and when the melt passes...

Embodiment 2

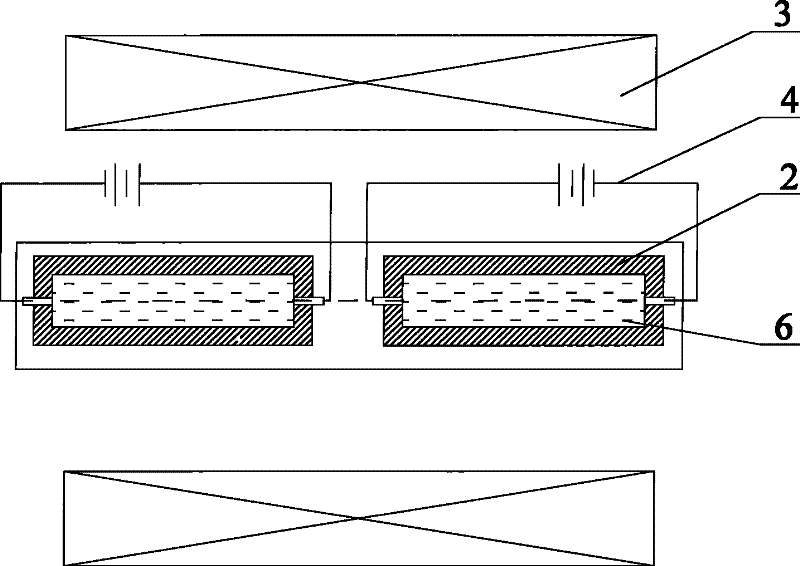

[0029] The magnetic field generating device 3 is fixed on the outside of the metal water-cooled crystallizer 5, such as image 3 , the graphite crystallizer 2 and the metal water-cooled crystallizer 5 are installed on the horizontal continuous casting furnace group 1. When the copper alloy liquid in the horizontal continuous casting furnace group 1 reaches 1000-1200 ° C, the tractor is started to start continuous casting, driving the copper The alloy slab 6 moves, one electrode of the DC power supply 4 is electrically connected to one side wall on the lateral side of the graphite crystallizer 2, and the other electrode of the DC power supply 4 is electrically connected to the other side wall on the lateral side of the graphite crystallizer 2 Through, a current loop is formed between the two side walls of the graphite crystallizer lateral side, and the current intensity is 50-500 amperes; the magnetic field generator 3 generates a magnetic field of 50-500 gauss, and when the mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com