Sheet adsorption device, transport device, and image forming apparatus

A technology of adsorption device and image, applied in printing device, transportation and packaging, printing and other directions, can solve the problems of increasing noise, not getting adsorption effect, generating air flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

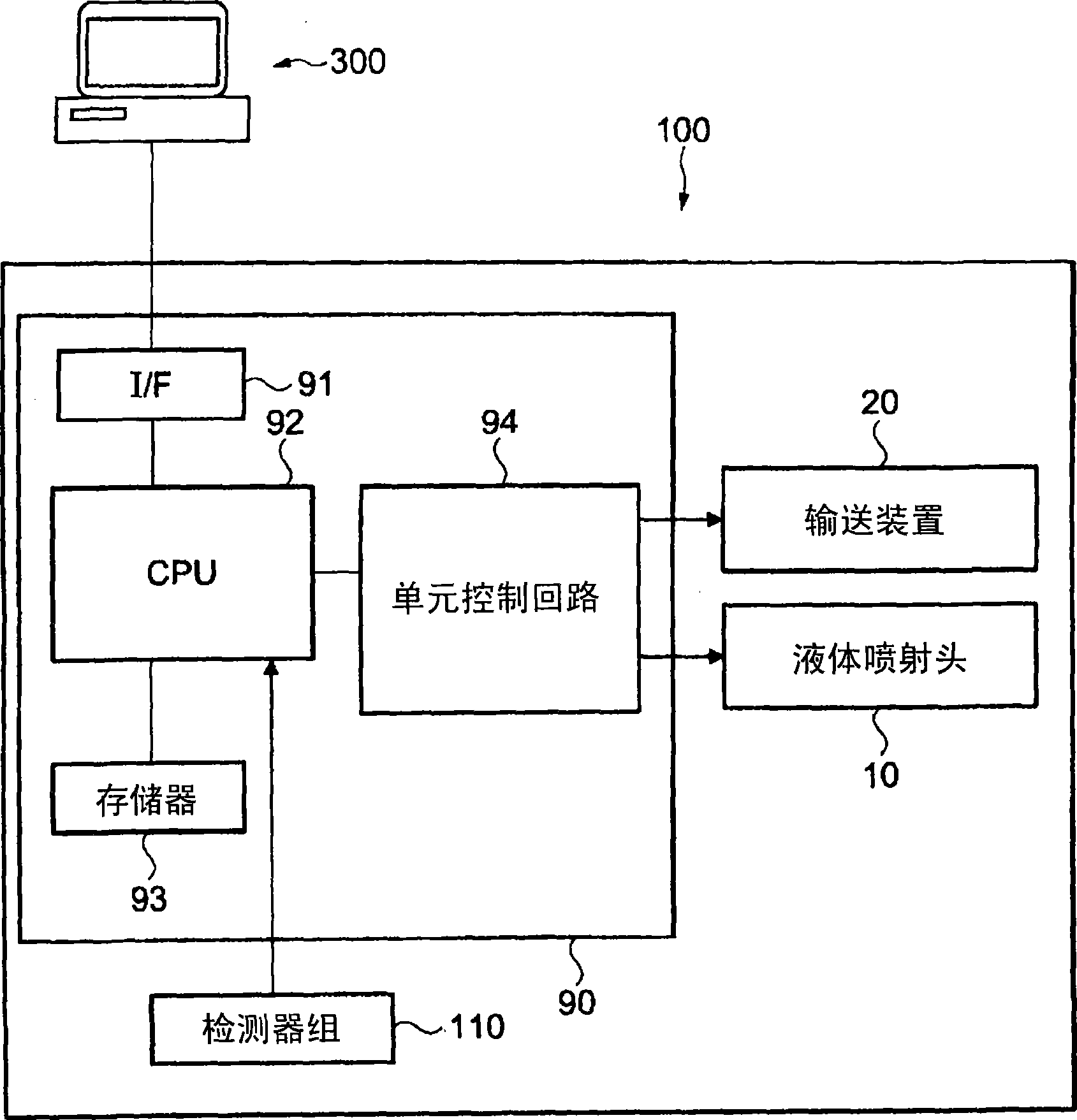

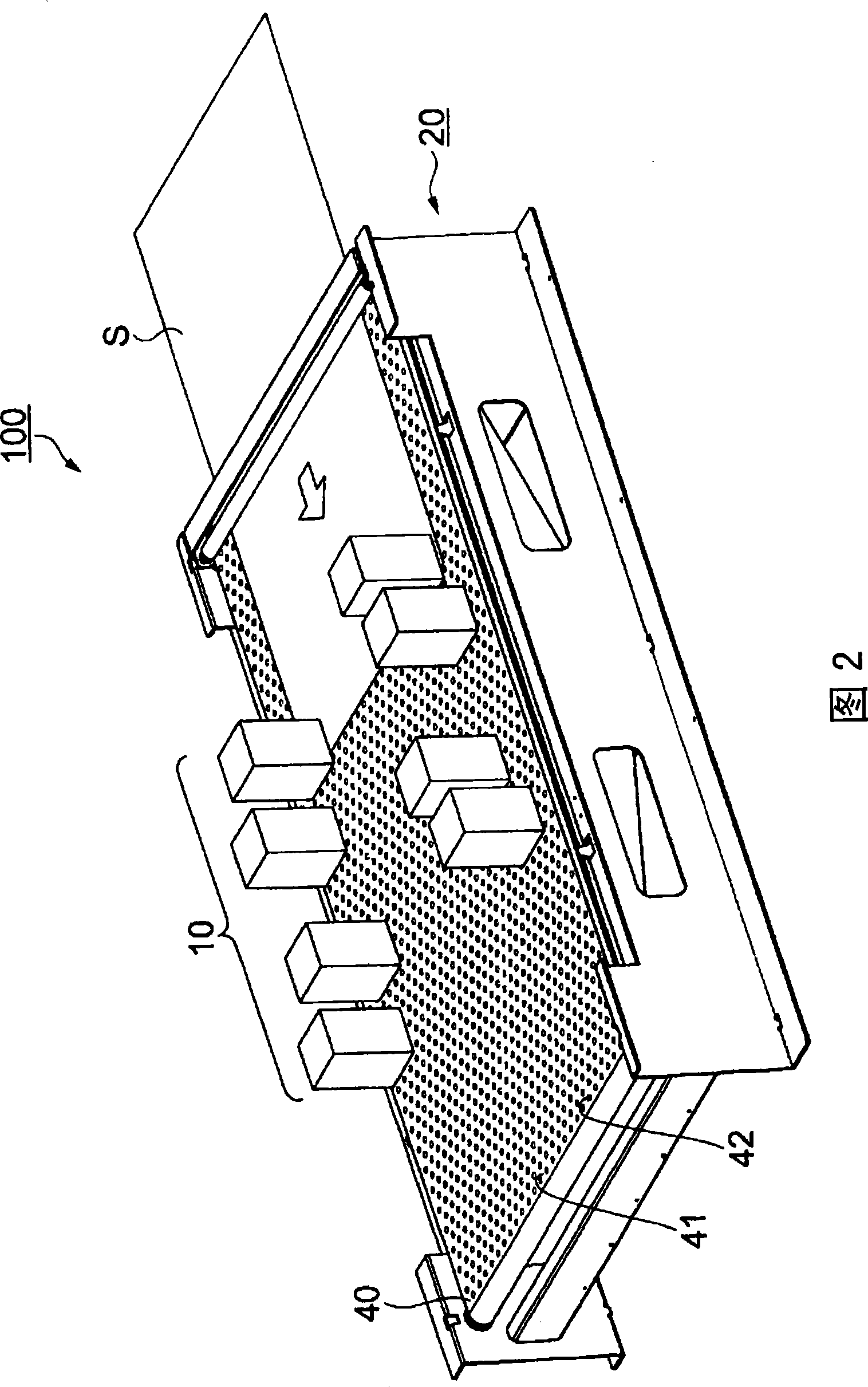

[0064] figure 1 A block diagram showing the overall configuration of the image forming apparatus 100 of this embodiment.

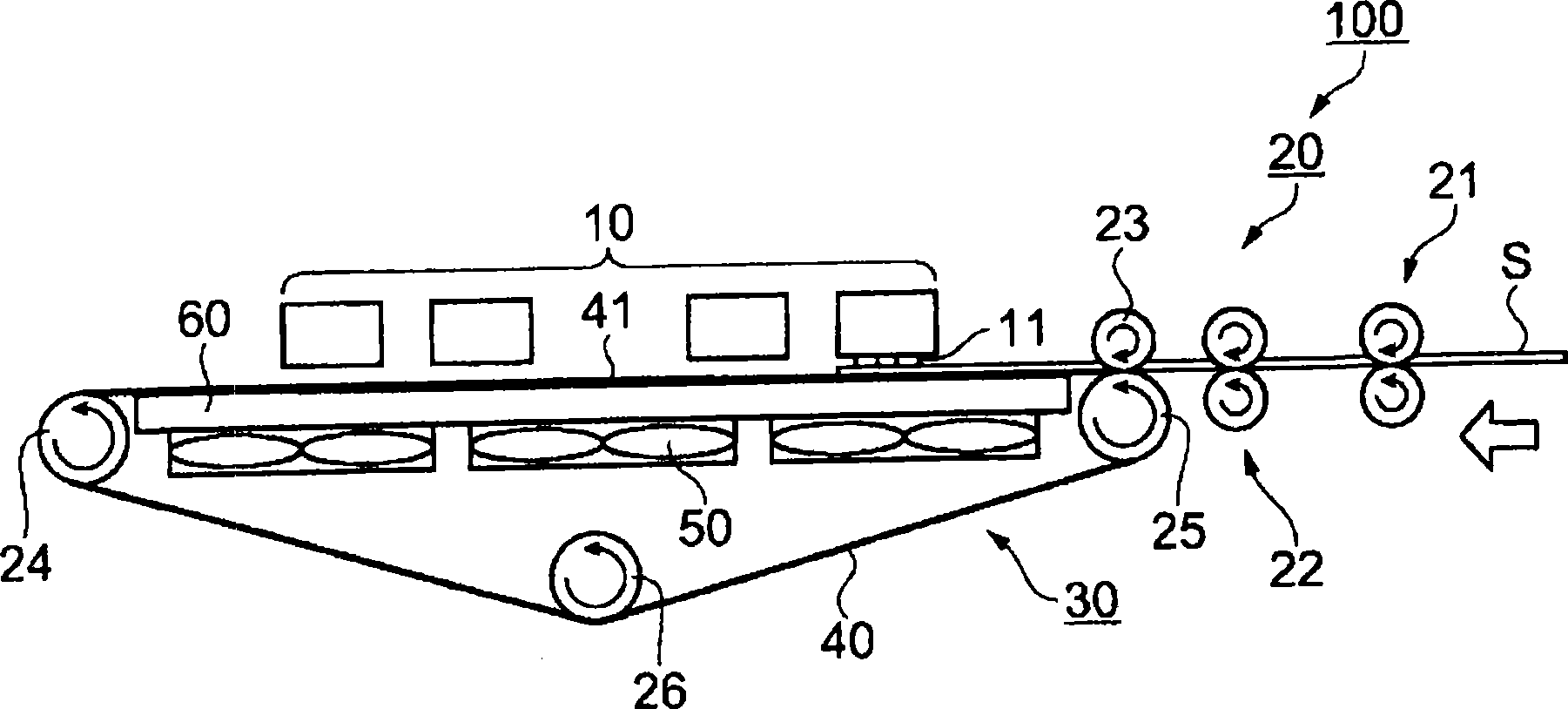

[0065] The image forming apparatus 100 that receives print data from a computer 300 as an external device controls the conveyance device 20 and the liquid jet head 10 through the controller 90 to form an image on the recording medium S that is a sheet. In addition, the condition in the image forming apparatus 100 is monitored by the detector group 110 , and the controller 90 controls the transport device 20 and the liquid jet head 10 based on the detection result.

[0066] The controller 90 is a control unit for controlling the image forming apparatus 100 . Interface unit (I / F) 91 is used to transmit and receive data between computer 300 and image forming apparatus 100 . CPU 92 is an arithmetic processing unit for controlling the overall image forming apparatus 100 . The memory 93 secures an area for storing programs of the CPU 92 , a work area, and th...

no. 2 approach

[0142] Figure 9 A schematic cross-sectional view of the image forming apparatus 200 of this embodiment is shown in . The image forming apparatus 200 of the present embodiment prints continuously on the recording medium S that is roll paper. The point different from the first embodiment is that the belt 40 is not included in the conveying device 85 .

[0143] exist Figure 9 Among them, the transport device 85 includes a paper feed roller 71 , a paper take-up roller 72 , and a sheet suction device 80 .

[0144] The recording medium S is conveyed from the paper feed roller 71 to the paper take-up roller 72 while being attracted to the sheet suction surface 612 . The sheet suction device 80 includes a fan 50 as a suction mechanism, and a static pressure control unit 60 .

[0145] In the sheet suction device 80 of the present embodiment, the sheet suction surface 612 is the same as that of the first embodiment. Figure 5 , Figure 7 and Figure 8 The side of the belt suppo...

no. 3 approach

[0152] Figure 10 A schematic cross-sectional view of the sheet suction device 66 included in the image forming apparatus of this embodiment is shown in . In the figure, arrows indicate the flow path of the gas in the case of suction by the fan 50 . In addition, a white arrow indicates the direction in which the recording medium S is transported. In addition, in this embodiment, the structure other than the sheet|seat adsorption|suction device 66 is the same as that of 1st Embodiment. Specifically, the static pressure controller 67 disposed between the belt 40 and the fan 50 in the sheet suction device 66 controls the suction state of each suction hole 42 , thereby switching the first state and the second state of the communication channel 600 .

[0153] Such as Figure 10 As shown, the sheet suction device 66 includes: a belt support plate 68 as a first plate-shaped member capable of supporting the recording medium S placed on the belt 40 via the belt 40; a main body 69 as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com