Pure electric drive system

A drive system, pure electric technology, applied in the direction of control drive, electric vehicles, electric power devices, etc., can solve problems such as unbalance, unable to place the center of gravity of high-power motors, etc., to avoid design difficulties, wide application range, and improve flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below with reference to the drawings.

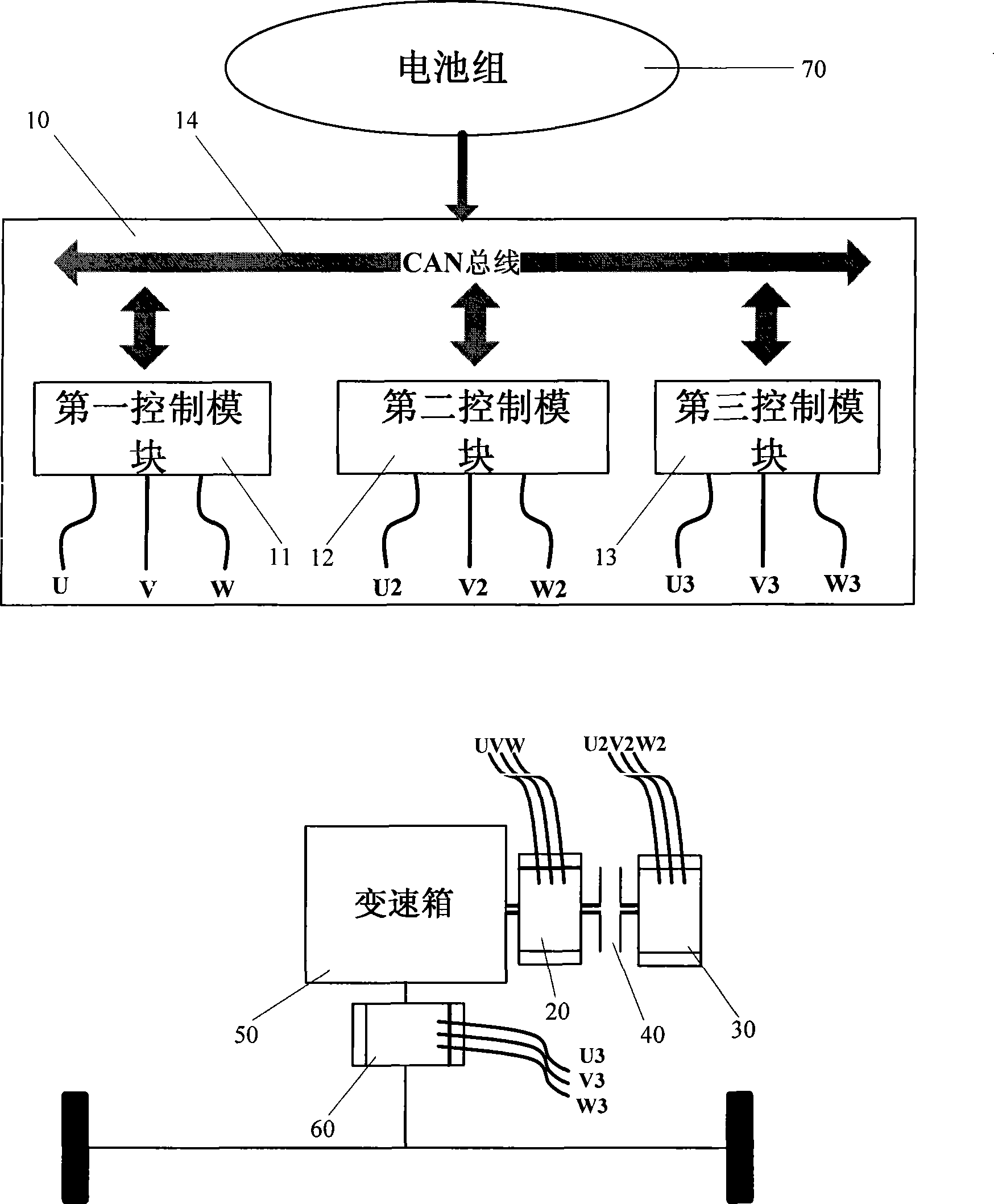

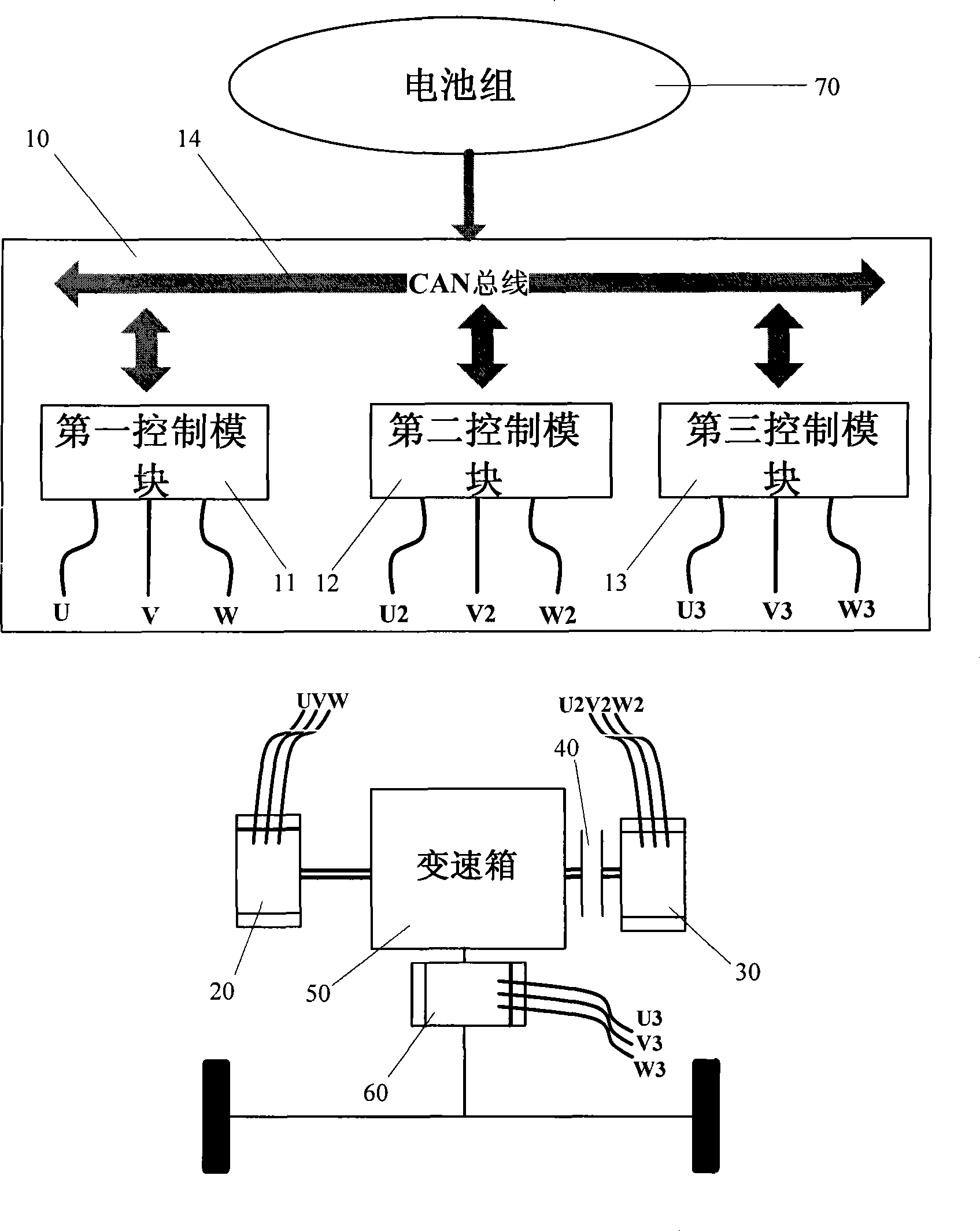

[0016] Such as figure 1 As shown, according to the present invention, a pure electric drive system is provided. The drive system mainly includes a battery pack 70, a gearbox 50, and a main drive motor. The battery pack 70 supplies power to the main drive motor. The box 50 inputs power, and the main driving motor includes a first main driving motor 20 and a second main driving motor 30. The drive system may also include a clutch 40, and the gearbox 50, the first main drive motor 20, the clutch 40, and the second main drive motor 30 are connected in sequence.

[0017] In other words, in figure 1 In the illustrated embodiment, the first main drive motor 20, the clutch 40, and the second main drive motor 30 are all arranged on the same side of the gearbox 50. The drive shaft of the first main drive motor 20 may be directly connected with the input shaft of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com