Method for rapidly judging phase of electric-controlled engine system

An electronically controlled engine and system phase technology, applied in engine control, machine/engine, electrical control, etc., can solve problems such as long judgment time and prolong engine start-up time, and achieve low cost, reduced start-up time, and less hardware changes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

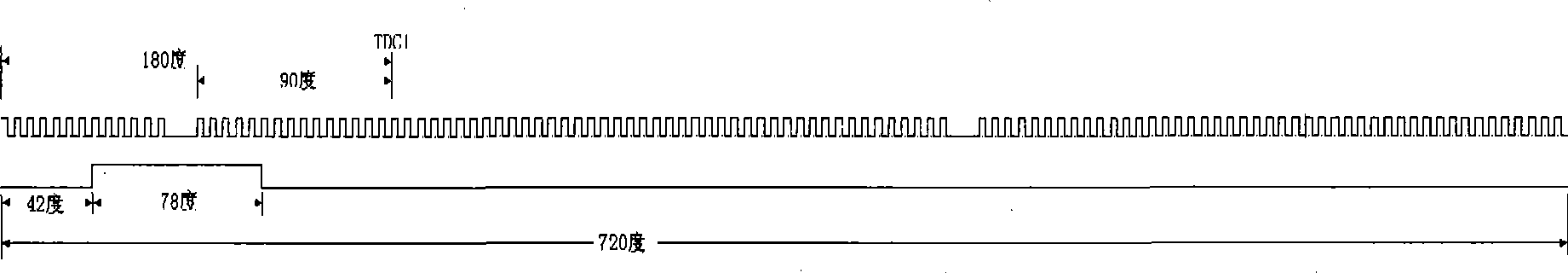

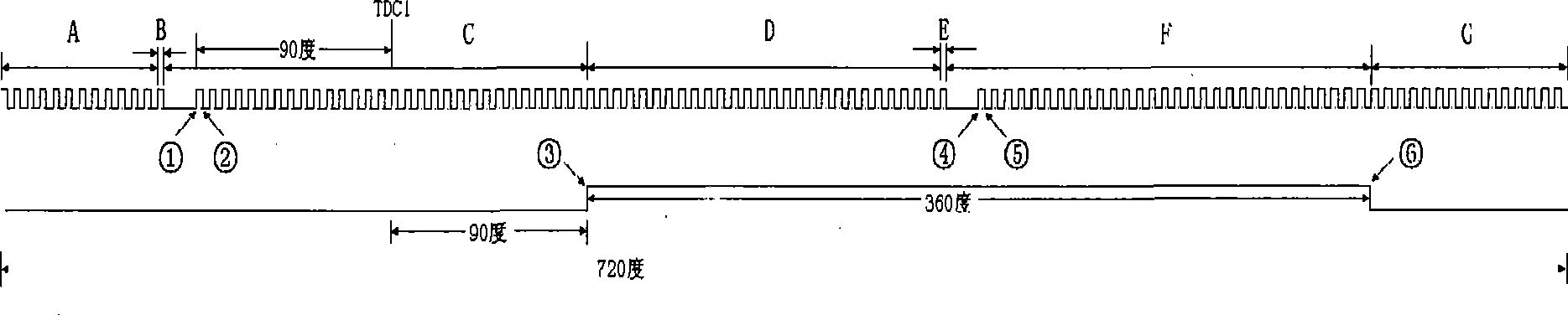

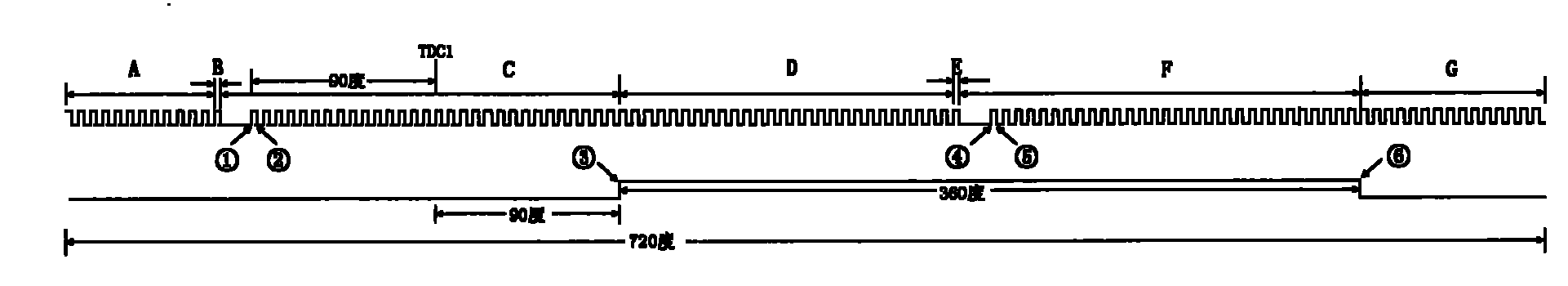

[0038] Such as figure 2 As shown, the crankshaft signal wheel of the electronically controlled engine in this embodiment has 58 teeth in total, and the width of the missing tooth set in the scope of the single tooth signal corresponding to the camshaft signal wheel of the crankshaft signal wheel is 2 times of the normal tooth interval. times. That is, the entire crankshaft signal wheel has 60 teeth with equal intervals, and two adjacent teeth are removed within the range corresponding to the single-tooth signal of the camshaft signal wheel, that is, 58 normal teeth, and two teeth are missing. The crankshaft rotation angle corresponding to the tooth width of the camshaft signal is 360 degrees, the starting position of the camshaft tooth profile signal corresponds to the 90 degree crankshaft angle after the compression top dead center of the first cylinder, and 180 degrees before the starting position of the camshaft tooth profile signal The end position of the crankshaft miss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com