All balance method for single cylinder diesel and mechanism thereof

A technology of balancing mechanism and diesel engine, which is applied in the direction of inertial force compensation, etc., can solve the problems of large number of mechanism parts, high cost, noise and environmental pollution, etc., and achieve the effect of reducing the space occupied by the body, reducing vibration and noise, and reasonable structural configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

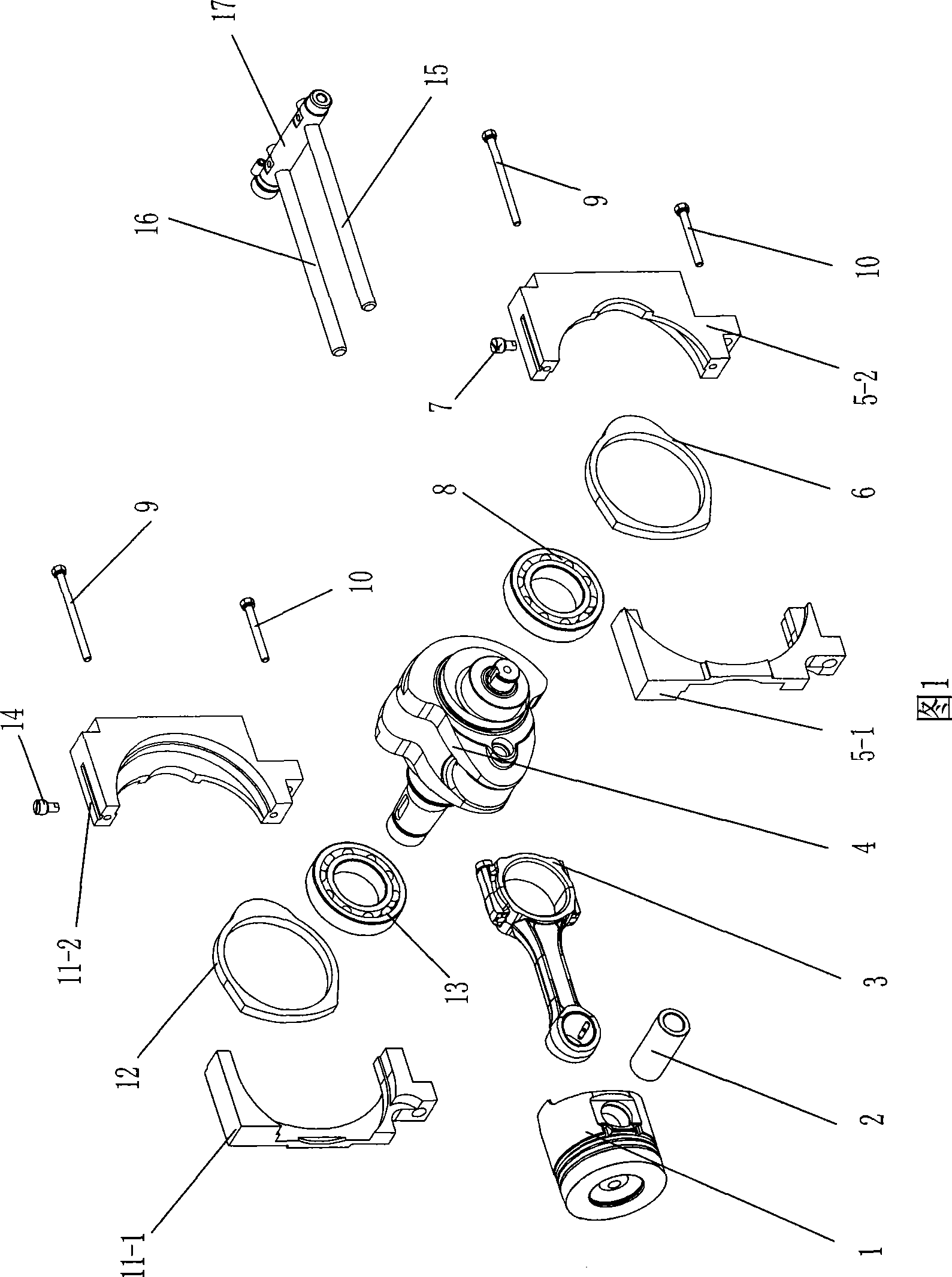

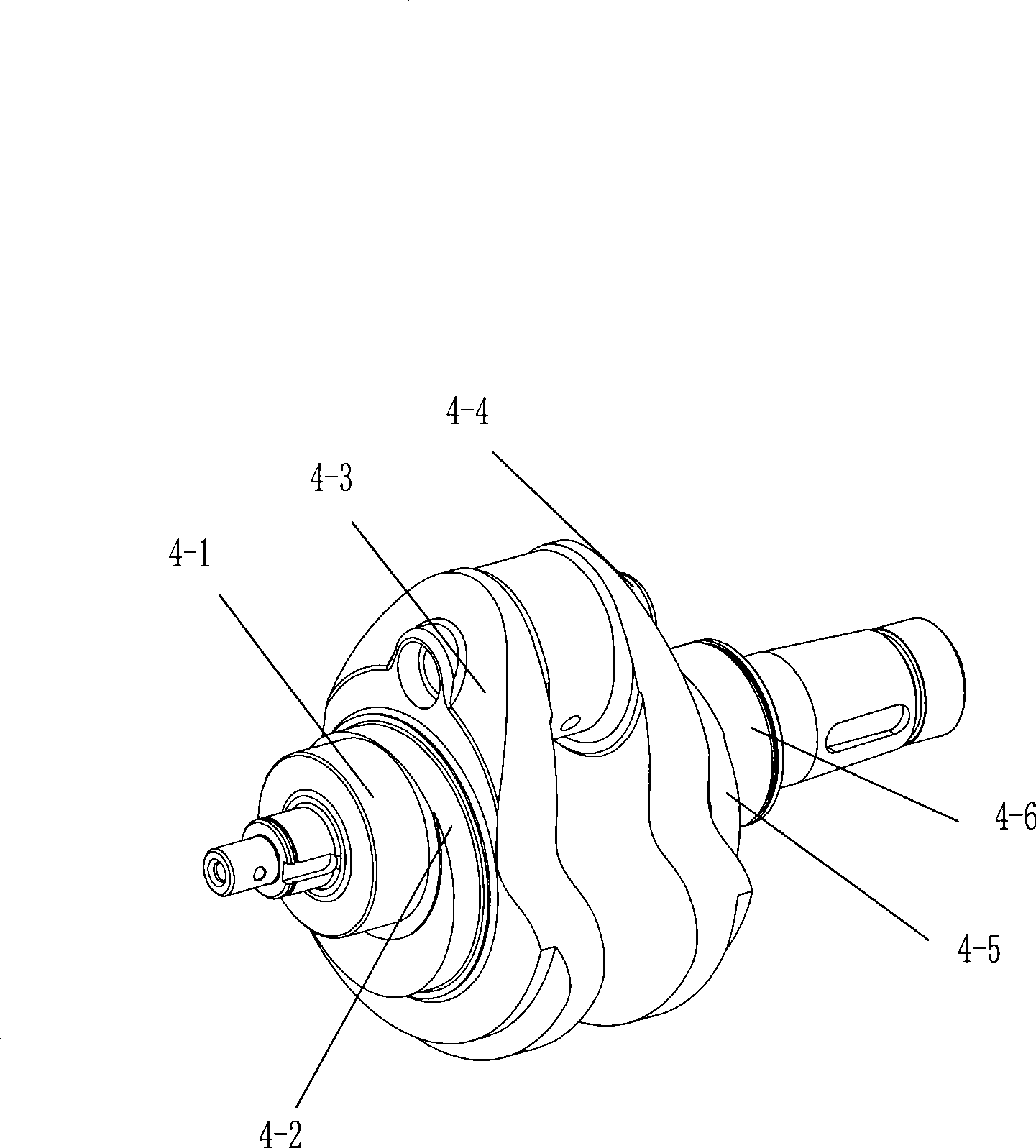

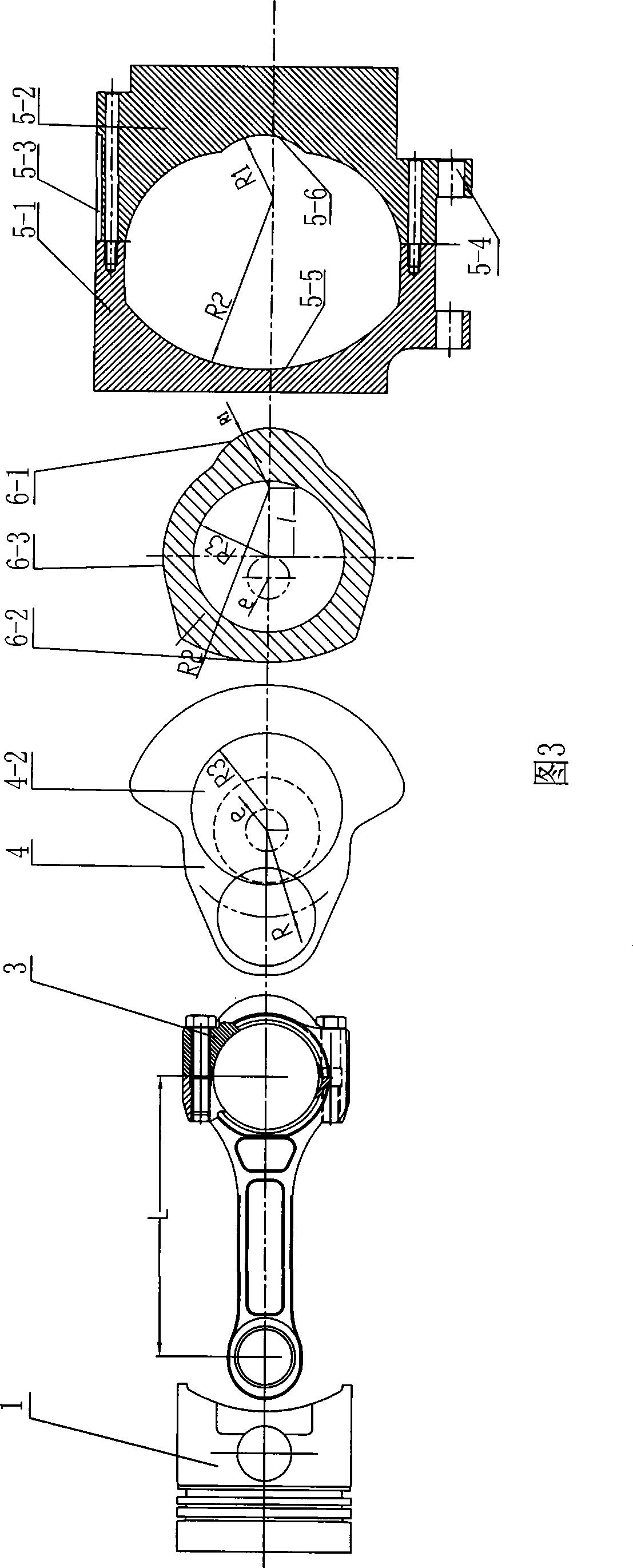

[0018] The single-cylinder diesel engine full balance method of the present invention drives the front and rear two ring-shaped connecting rods 6 and 12 respectively through the front and rear two bearings 8 and 13 installed on the two eccentric journals 4-2 and 4-5 of the crankshaft 4, and the front and rear two ring-shaped connecting rods 6 and 12 are respectively driven. , the two ends of rear two annular connecting rods 6 and 12 have left big, right small arc surface, as the big end and small end of front and rear two annular connecting rods 6 and 12, front and rear two annular connecting rods 6 and 12 along The left and right guide arcs of the front and rear sliders 5 and 11 are rotated and swung in a plane, and the front and rear sliders 5 and 11 are pushed to reciprocate in the body 18. The front and rear sliders 5, 11 The reciprocating trajectory of 11 is collinear with the trajectory of piston 1 and the direction of movement is opposite. When the ratio of the eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com