Large caliber rubber positive and negative flexible pipe of shield machine

A large-diameter, shield machine technology, applied in the direction of hoses, pipes, lamination, etc., can solve problems such as pipe joints are easy to fall off, fail to meet technical requirements, and separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

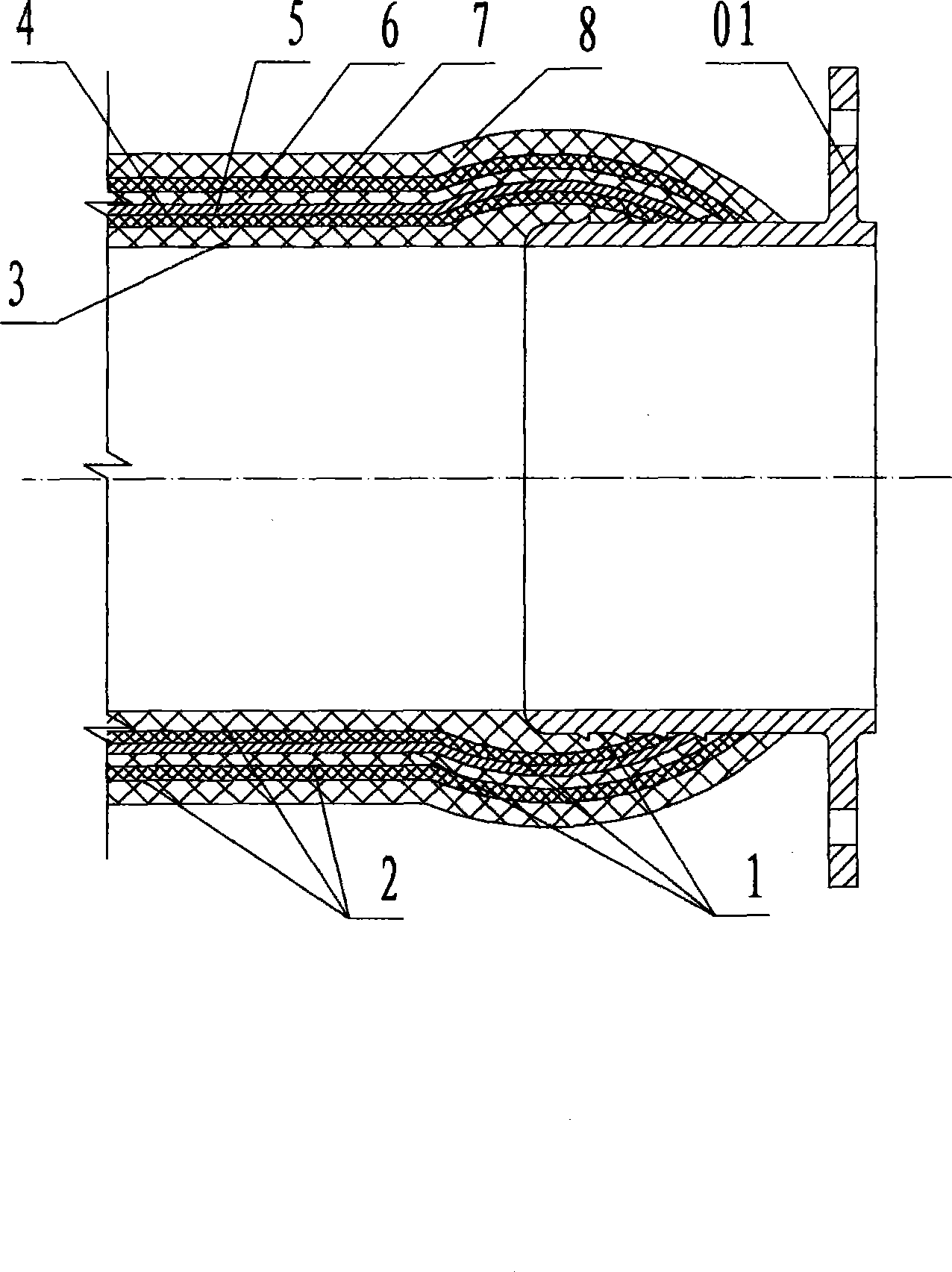

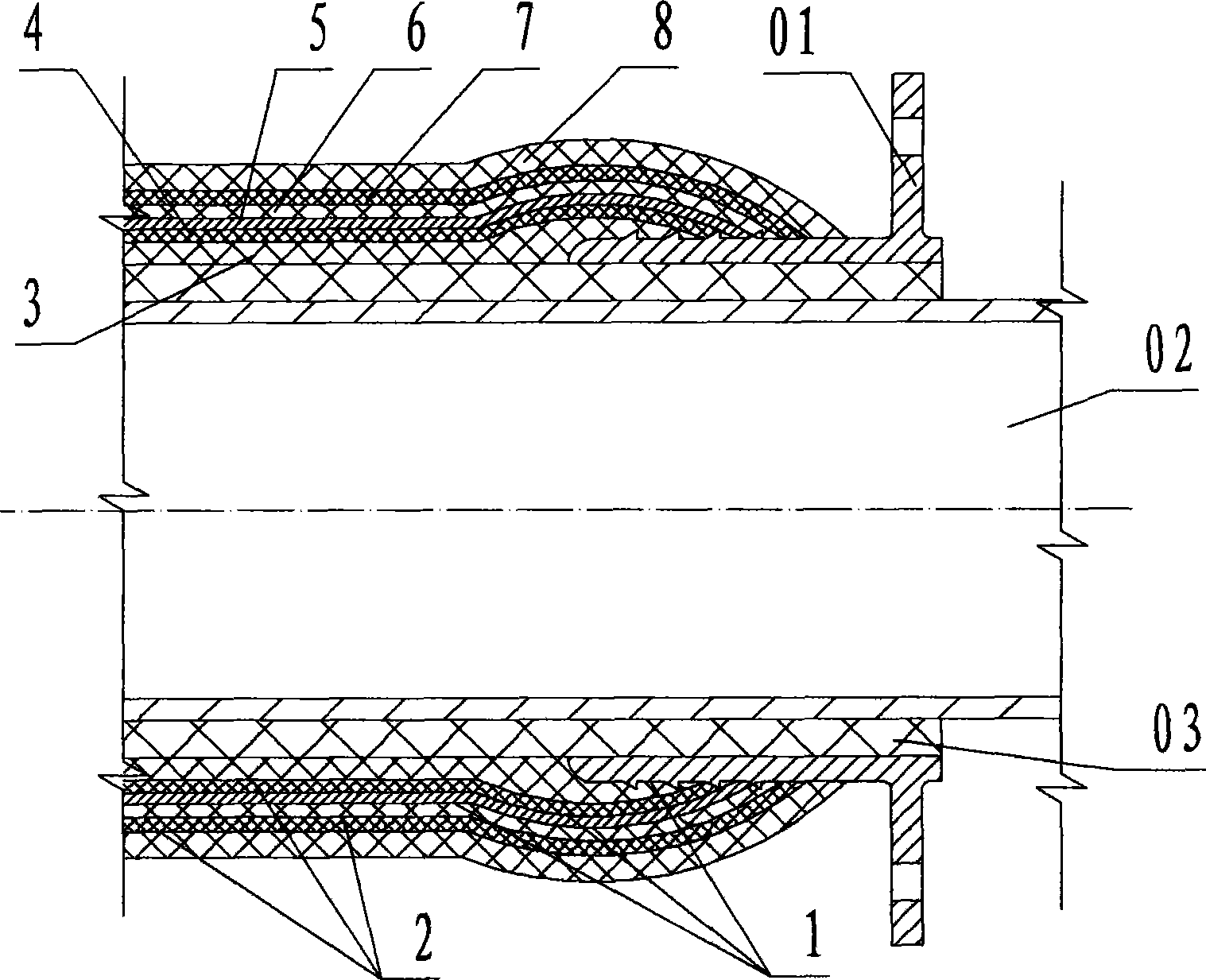

[0014] refer to figure 1 , figure 2 , a shield machine large-diameter rubber positive and negative pressure hose of the present invention includes gold glue adhesive 1, curtain glue adhesive 2, inner glue 3, inner cord 4, steel wire 5, middle glue 6, middle cord 7, outer Glue 8, wherein: the gold glue adhesive 1 is used for the glue adhesive between metal and rubber, the product name is Chemlok CH-205; the described curtain glue adhesive 2 is used between the cord and rubber The glue adhesive, the product name is Kemlok CH-20; the inner rubber 3 is a mixed rubber of natural rubber and butadiene rubber; the inner cord 4 is nylon cloth; the steel wire 5 is 70 # carbon steel wire; the middle rubber 6 is natural rubber; the middle cord 7 is nylon cloth; the outer rubber 8 is natural rubber.

[0015] Production process:

[0016] On the pre-embedded surface of the pre-embedded metal flange 01 clamped on the winding mandrel 02 with the release layer 03 in the pipe winding machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com