Multi-stage dry voltage regulating transformer

A voltage regulating transformer, dry-type technology, applied in transformers, variable transformers, transformer/inductor cooling, etc., can solve the problems of high price, tripping and power failure, low capacity of oil-immersed transformers, etc., to achieve increased capacity and voltage regulation The effect of large range and meeting the requirements of equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

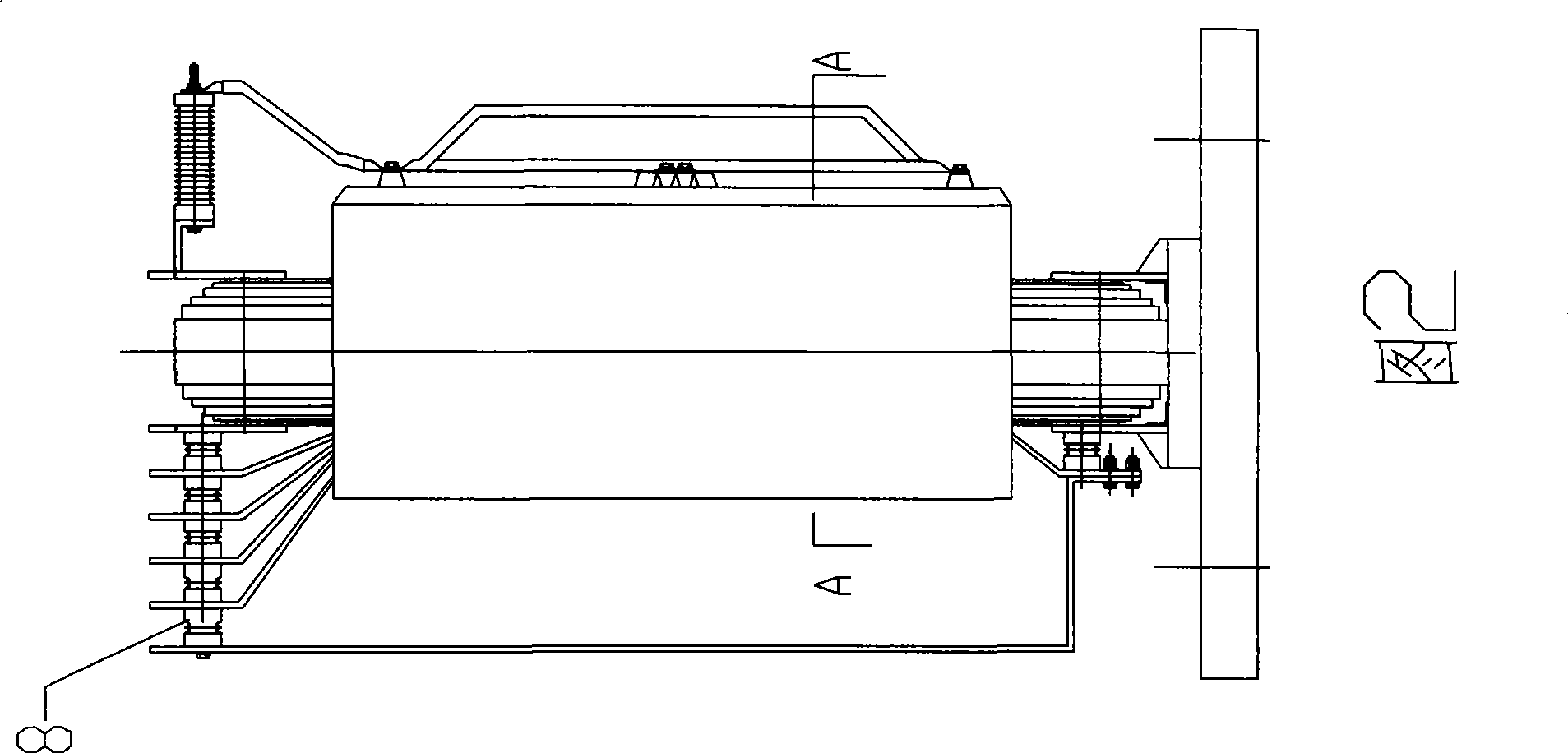

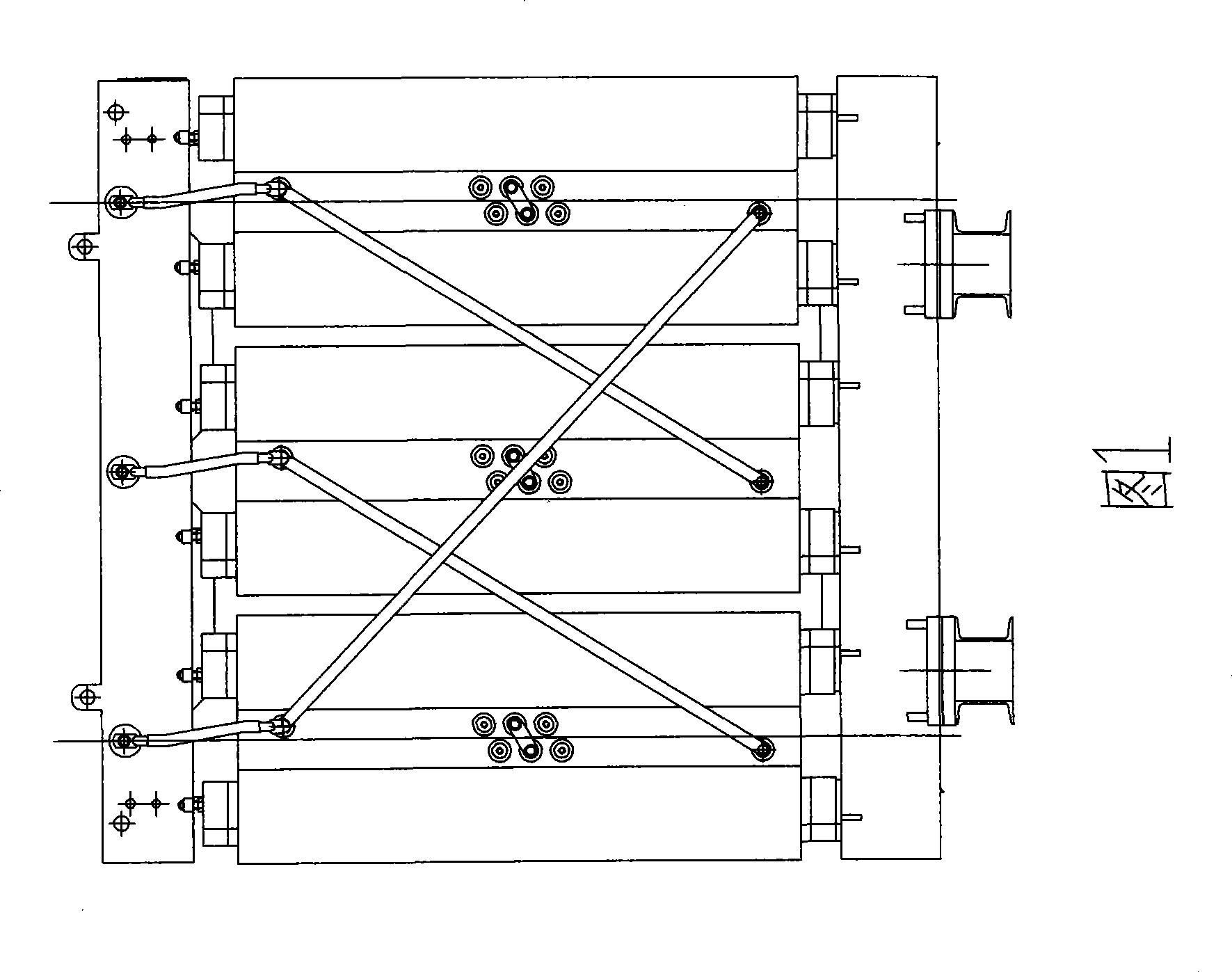

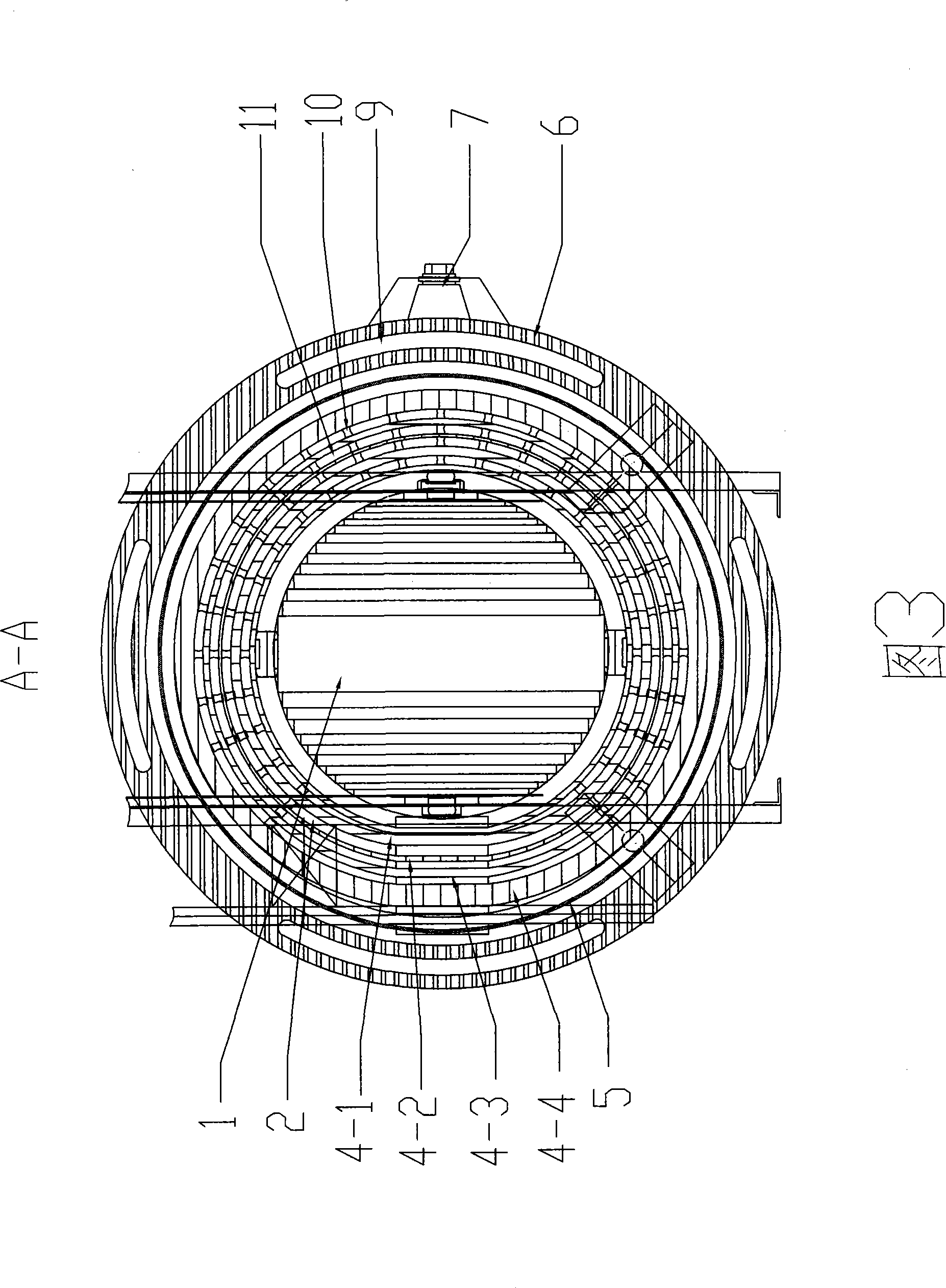

[0012] The invention is a multi-stage dry-type transformer, which realizes multi-stage voltage regulation by using a plurality of low-voltage coils 4 sets to form a low-voltage winding. That is, it includes iron core 1, upper and lower clamps 2, high and low voltage windings, etc. On the iron core 1 of the high and low voltage winding set, the upper and lower clamps 2 are set at the upper and lower ends of the iron core 1, and an insulating cylinder is arranged between the high and low voltage windings 5. There are no less than 2 low-voltage coils 4 in the low-voltage winding in the winding, and the low-voltage coils 4 are assembled sequentially from outside to inside according to the voltage level. Each low-voltage coil 4 is equipped with a tap 7, and the other end of the tap 7 is insulated from the low-voltage output of the transformer. Terminal 8 connection. In this way, the number of low-voltage and current gears (such as 2nd gear, 3rd gear, 4th gear, 6th gear, or even 8t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com