Non-position sensor vector control method for double-feed wind power generator

A wind turbine, vector control technology, applied in the direction of motor generator control, vector control system, electronic commutation motor control, etc., can solve the problems of reduced system reliability, increased cost, increased maintenance cost, etc., to achieve anti-interference The effect of improving capacity and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

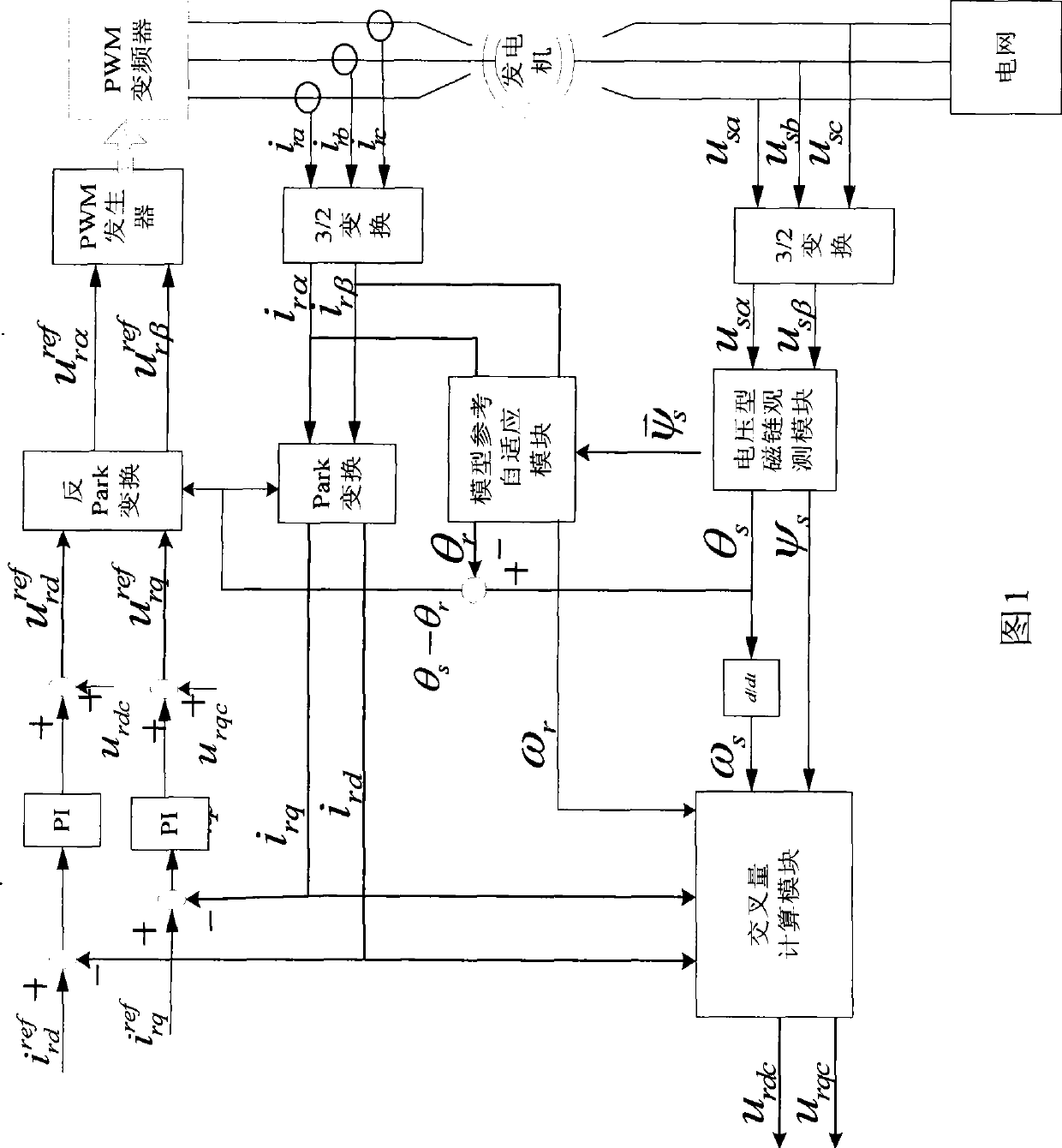

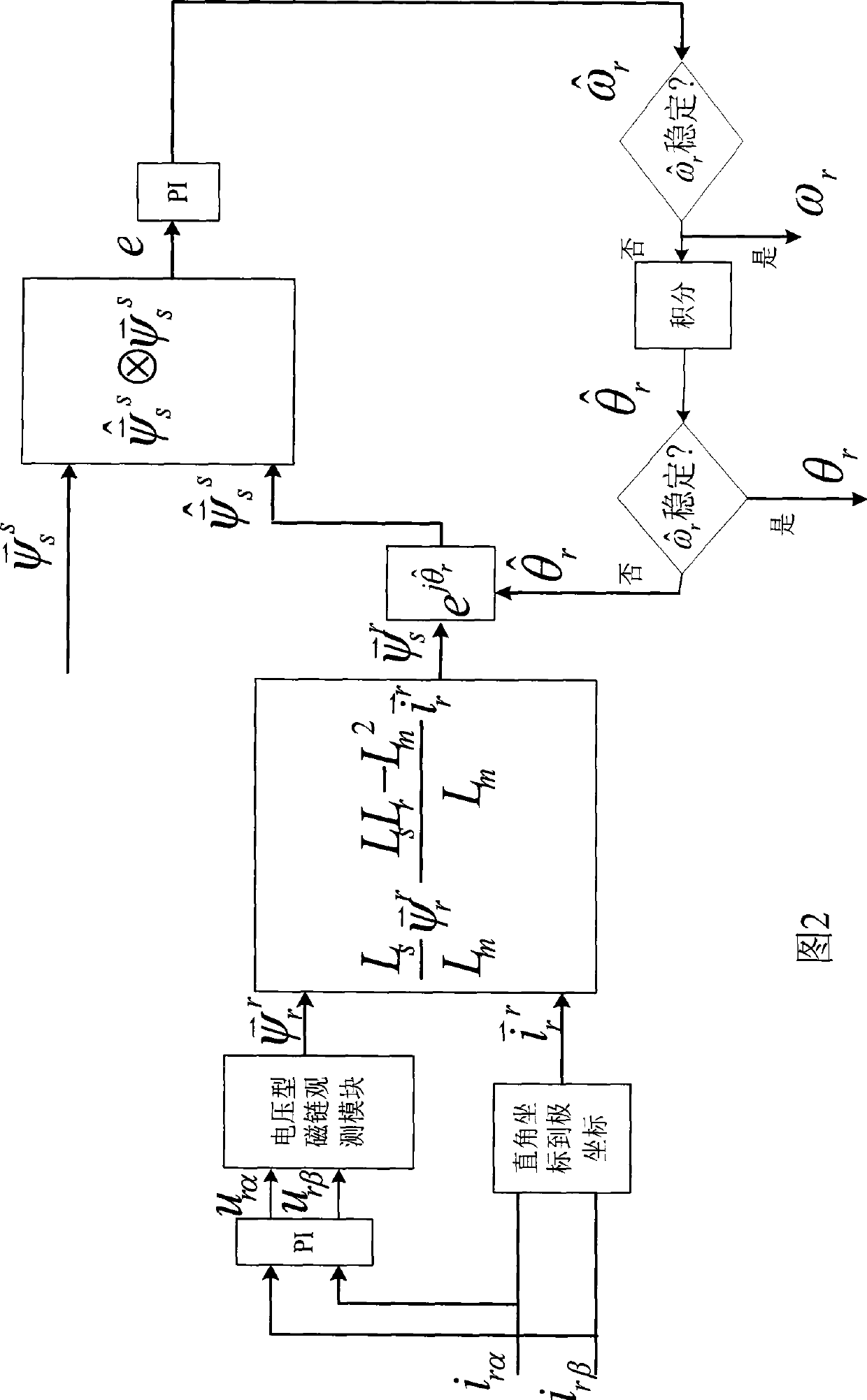

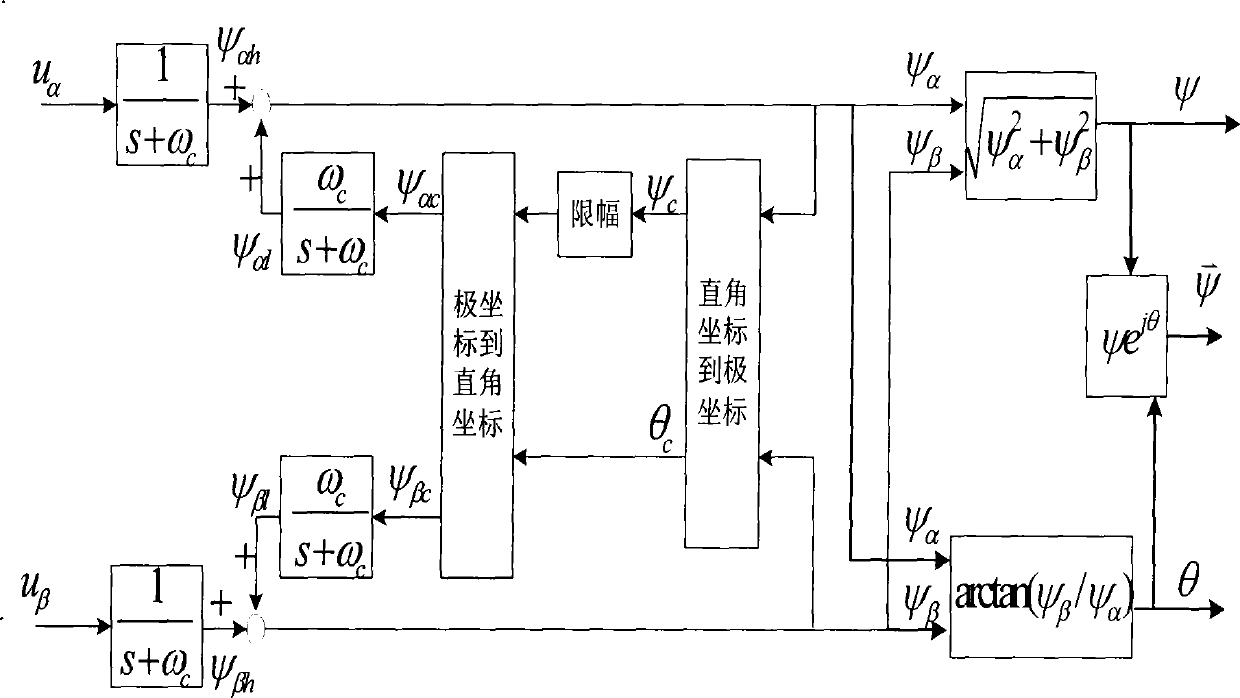

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] The doubly-fed generator is a nonlinear, strongly coupled, multivariable system, and its electromechanical energy conversion is accomplished through the fundamental magnetic field. Therefore, in order to simplify the mathematical model, usually only consider the effect of the air-gap fundamental magnetic field of the DFIG, and ignore the iron loss and ferromagnetic nonlinearity, the skin effect of the winding, and the temperature rise of the stator and rotor windings. Accordingly, in the synchronous rotating coordinate system, when both the stator and the rotor adopt the motor convention, the mathematical model of the doubly-fed generator is:

[0024] u → s = R s i → s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com