Large intelligent greenhouse energy saving separation independent production system

A production system and greenhouse technology, which is applied in the field of large-scale intelligent greenhouse energy-saving and separated independent production systems, can solve the problems of high energy consumption and high operation and management costs, achieve high output, reduce greenhouse energy consumption, and reasonably utilize resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

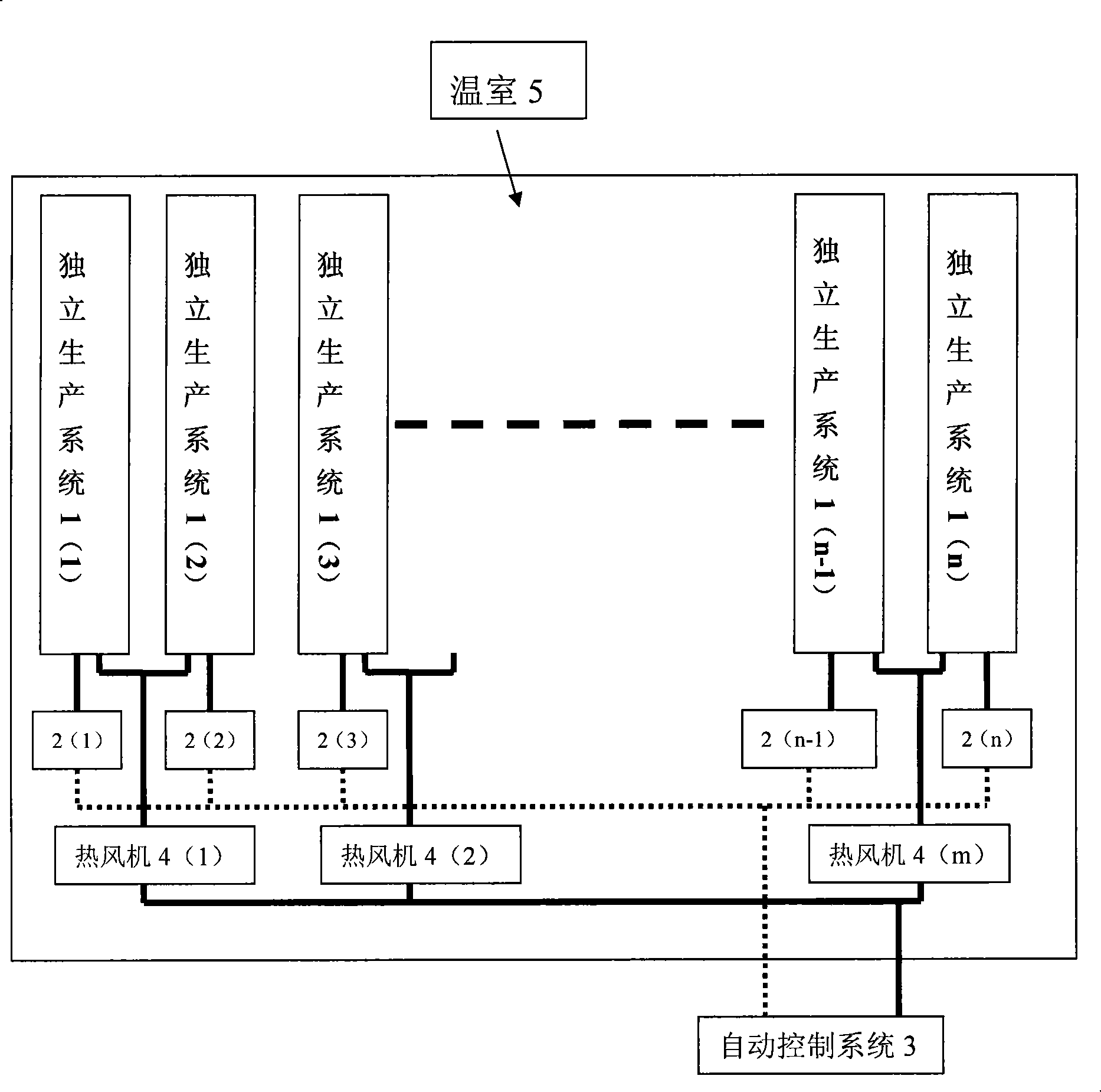

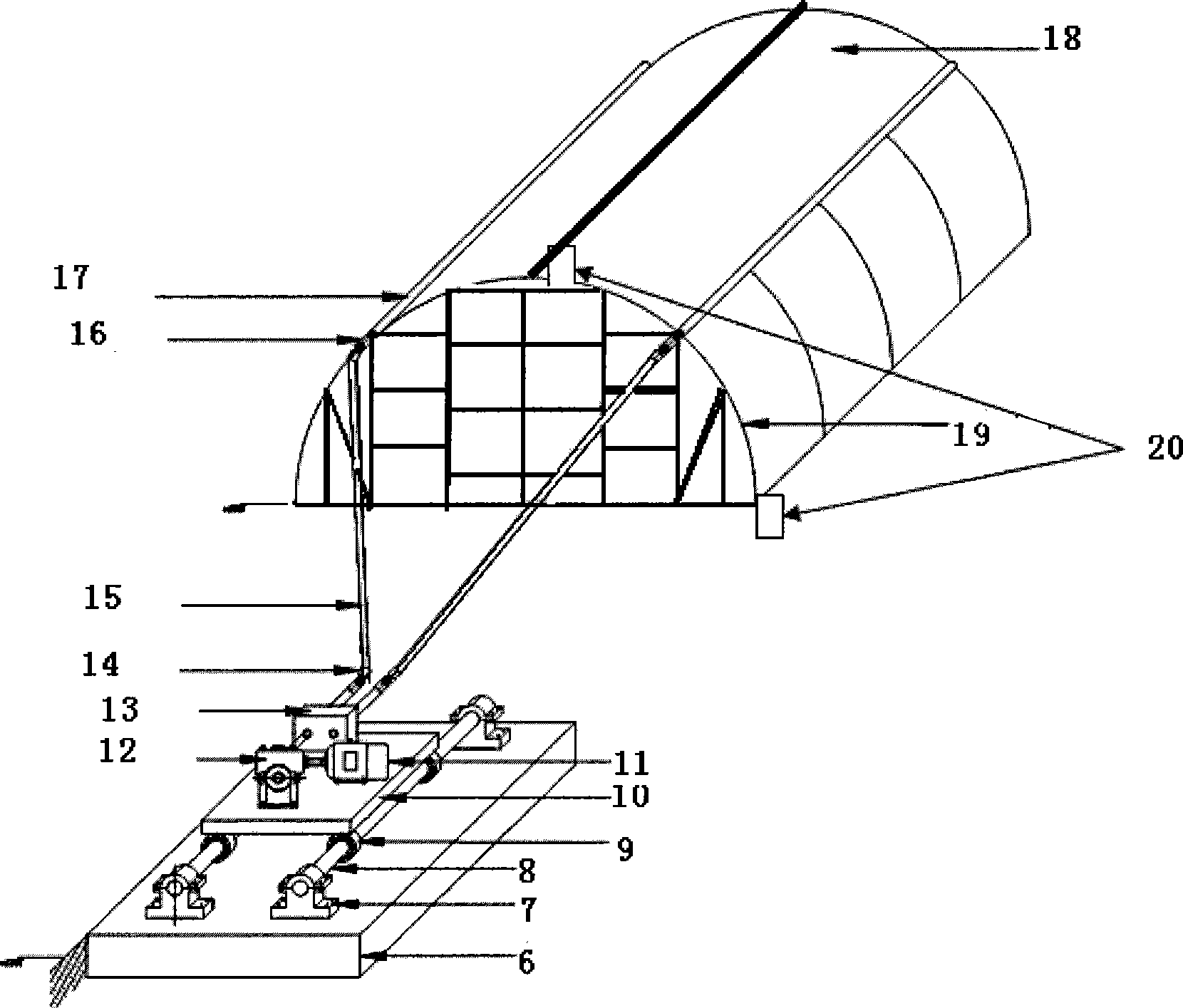

[0031] Embodiment 1: the present invention is made up of independent production system 1, automatic film rolling machine 2, automatic control system 3, hot air blower 4 and greenhouse 5, and its structure is as follows figure 1 and figure 2 shown. Among them, the independent production system 1, the automatic film rolling machine 2, the automatic control system 3 and the hot air blower 4 are all located in the greenhouse 5; the automatic film rolling machine 2 is connected with the independent production system 1 through the film rolling shaft 17; the automatic film rolling machine 2 Connected with automatic control system 3 through twisted pair; hot air blower 4 is directly connected with independent production system 1 for heating of independent production system 1; hot air blower 4 is connected with automatic control system 3 through wires; heat preservation curtain 18 Covered on the independent production system 1, it is used for the insulation of the independent product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com