Vacuum brazing technique of stainless steel plate fin structure

A technology of stainless steel plate and brazing process, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of many structural defects and low strength, improve reliability, ensure brazing quality, and optimize vacuum brazing The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

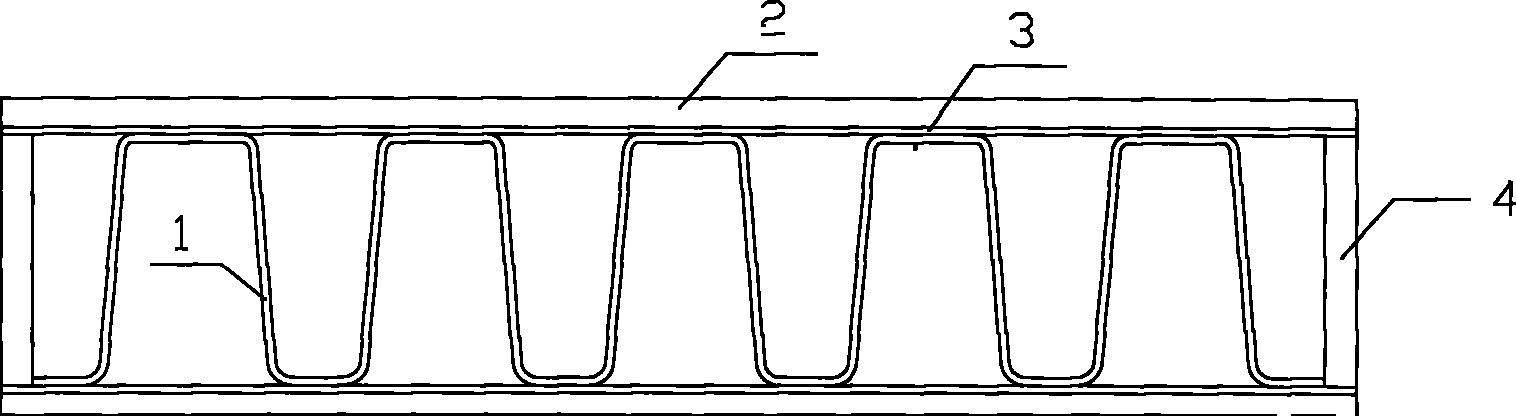

[0018] Embodiment 1: A stainless steel plate fin structure, composed of fins (1), partitions (2), seals (3) and so on. The material of the fin and the partition is 304 stainless steel, the thickness of the fin is 0.2mm, and the thickness of the partition is 0.4mm. The solder uses nickel-based solder BNi2 with a thickness of 105μm. First put a fin on the partition (metal plate), and then put a partition on it. A solder foil is pre-installed between the fin and the partition, and then both sides are sealed with edge seals to form a basic unit (such as Shown in Figure 1). After stacking a lot of basic units and clamping them firmly with a special brazing fixture designed by the inventor, the applied pressure is 5MPa, put into a vacuum brazing furnace, and a stainless steel plate-fin structure is made by vacuum brazing.

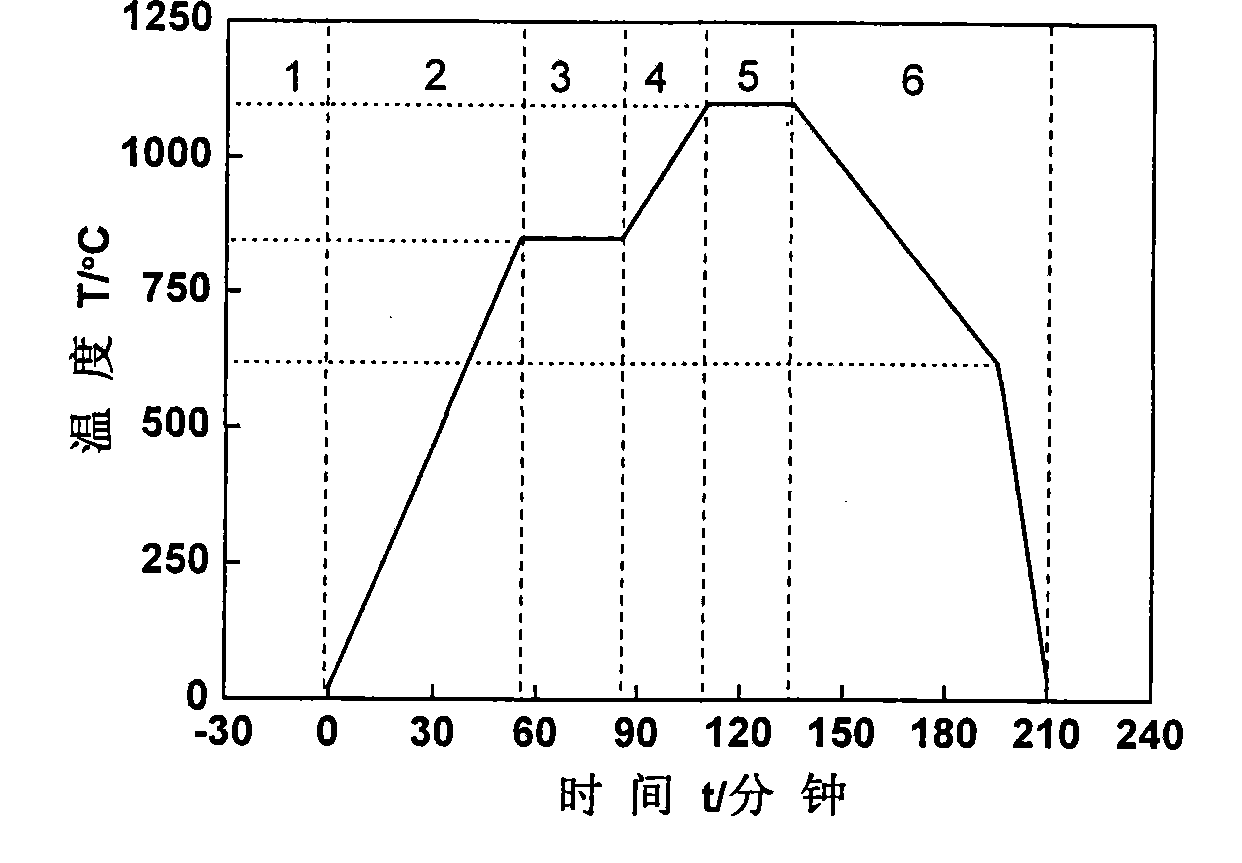

[0019] The vacuum brazing heating process consists of the following six steps:

[0020] The first step is the vacuum stage: the vacuum degree is 1×10 -3 Pa. Its p...

Embodiment 2

[0027] Embodiment 2: A stainless steel plate fin structure, consisting of fins (1), partitions (2), seals (3) and so on. The material of the fin and the partition is 304 stainless steel, the thickness of the fin is 0.2mm, and the thickness of the partition is 0.4mm. The solder uses nickel-based solder BNi2, and the thickness of the solder is 110μm. First put a fin on the partition (metal plate), and then put a partition on it. A solder foil is pre-installed between the fin and the partition, and then both sides are sealed with edge seals to form a basic unit (such as Shown in Figure 1). After stacking a lot of basic units and clamping them firmly with a special brazing fixture designed by the inventor, the applied pressure is 5MPa, put into a vacuum brazing furnace, and a stainless steel plate-fin structure is made by vacuum brazing.

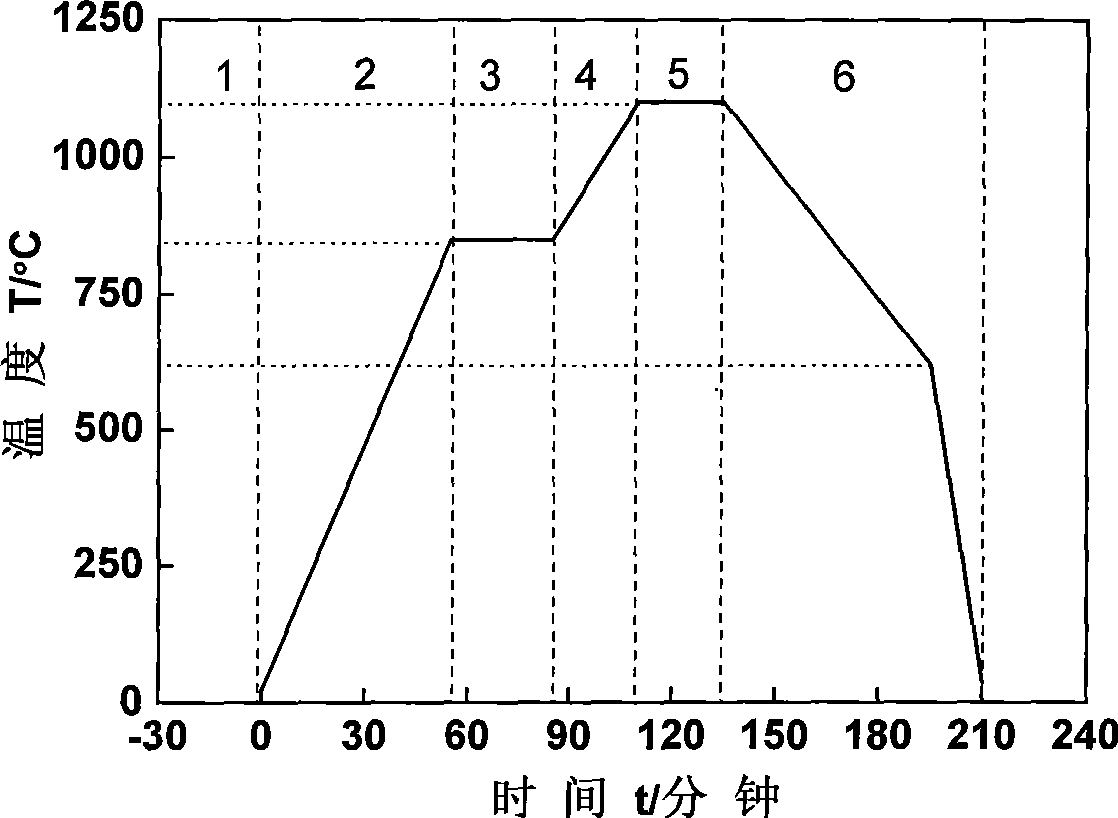

[0028] The vacuum brazing heating process consists of the following six steps:

[0029] The first step is the vacuum stage: the vacuum degree is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com