Method for preparing porous silicon dioxide nano sphere with special structure on surface and porous silicon dioxide nano sphere

A technology of porous silica and special structure, applied in the direction of silicon oxide, nanostructure manufacturing, nanotechnology, etc., to achieve the effects of controllable material structure and morphology, high thermal stability, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

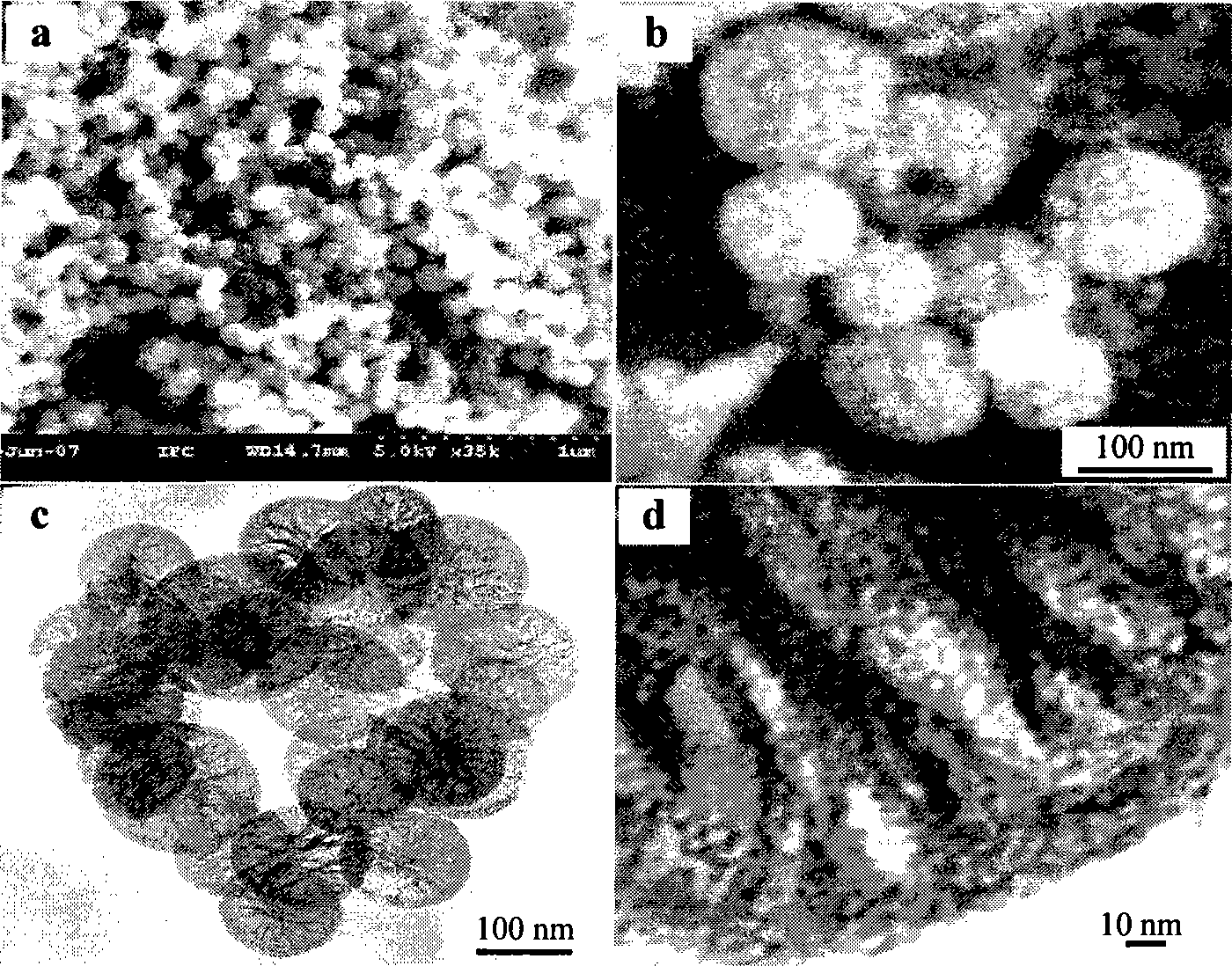

[0041] Dissolve 0.2-0.5 g of cetyltrimethylammonium bromide in 30-50 ml of distilled water (conductivity 18.2 MΩ), stir at room temperature for 10-20 minutes, respectively add 0.2-0.3 ml of 25 wt% ammonia water, 10-30 Add milliliters of anhydrous ether into the solution, stir rapidly for 10-20 minutes, add 1-1.5 milliliters of tetraethoxysilane (purity not less than 99.9%) into the solution, seal and keep stirring for 14-34 hours. The solid precipitate obtained by the reaction is filtered, washed with water, dried in air at 50-70 degrees Celsius, and finally calcined at 400-700 degrees Celsius for 4-6 hours. Take a small amount of dried sample and redisperse it in ethanol, spot it on the copper grid for transmission electron microscope observation, then observe with transmission electron microscope and scanning electron microscope, as figure 1 shown in a and 1c.

[0042] figure 1 a, b and figure 1 c, d are scanning electron micrographs and transmission electron micrographs ...

Embodiment 2

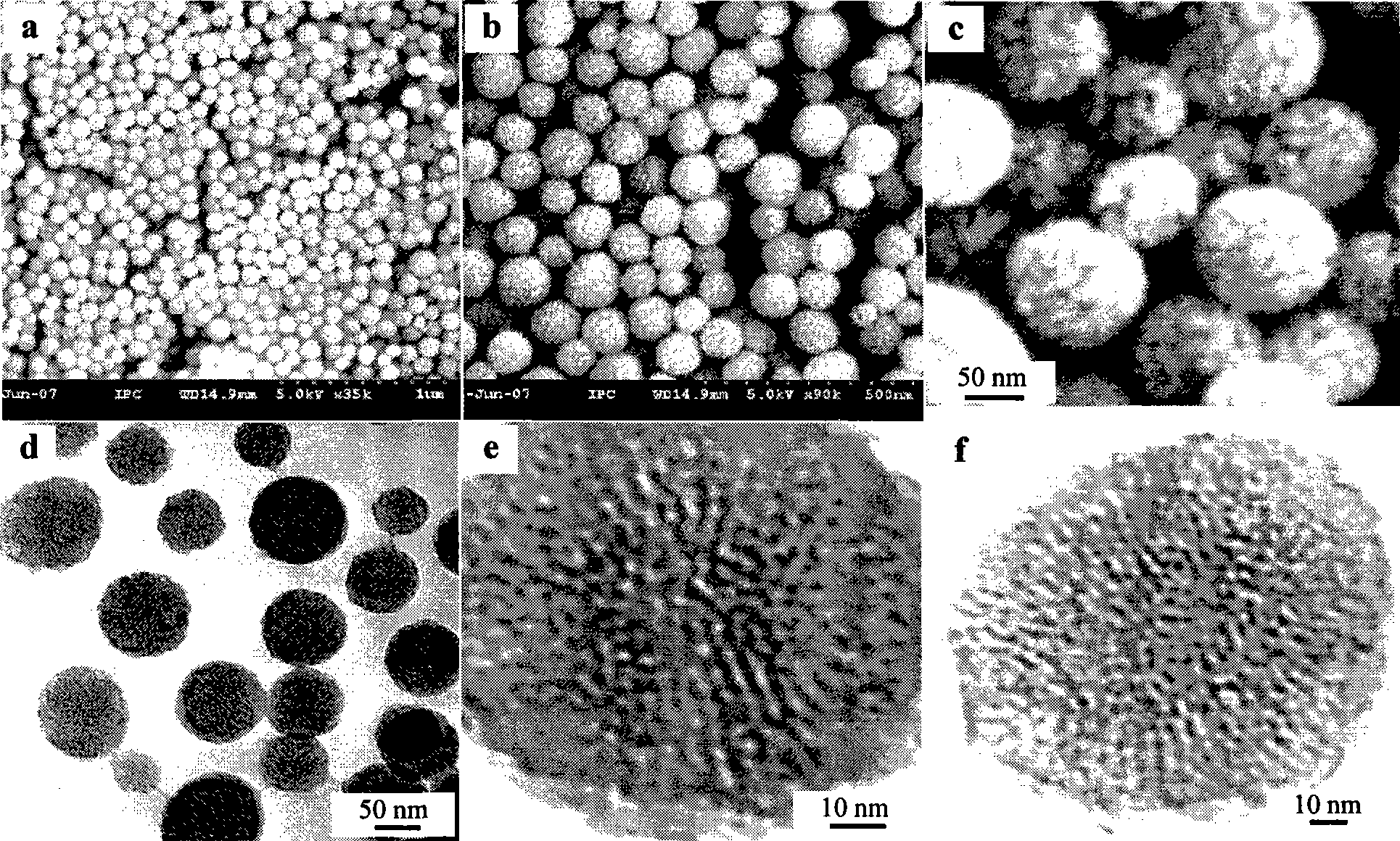

[0044] Dissolve 0.2-0.5 g of cetyltrimethylammonium bromide in 30-50 ml of distilled water (conductivity 18.2 MΩ), stir at room temperature for 10-20 minutes, respectively add 0.2-0.3 ml of 25 wt% ammonia water, 10-30 Add milliliters of ethylene glycol monoethyl ether into the solution, stir rapidly for 10-20 minutes, add 1-1.5 milliliters of tetraethoxysilane (purity not less than 99.9%) into the solution, seal and keep stirring for 20-26 hours. The solid precipitate obtained by the reaction is filtered, washed with water, dried in air at 50-70 degrees Celsius, and finally calcined at 400-700 degrees Celsius for 4-6 hours. Take a small amount of dried sample and redisperse it in ethanol, spot it on the copper grid for transmission electron microscope observation, then observe with transmission electron microscope and scanning electron microscope, as figure 2 a-c and 2d-f are shown.

[0045] figure 2 It is a scanning electron micrograph and a transmission electron microgra...

Embodiment 3

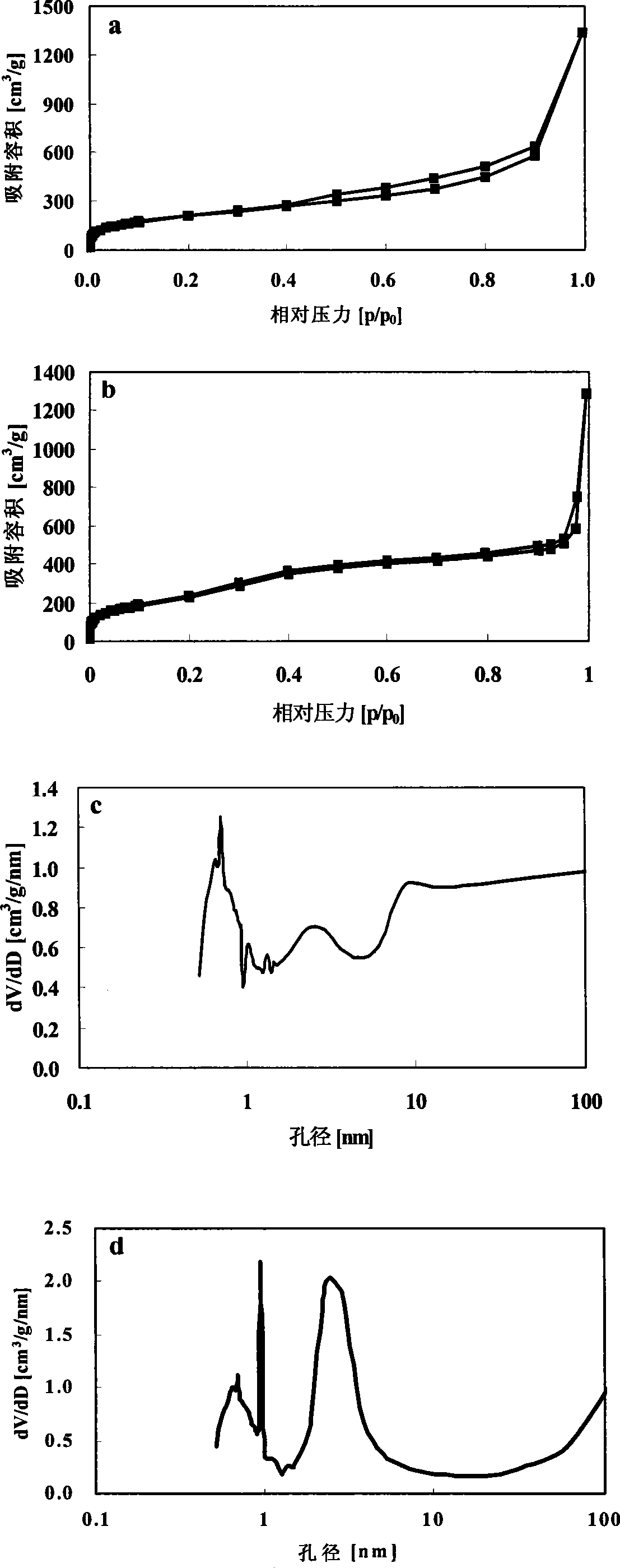

[0047] Get the porous silica nanospheres with a special structure on the surface and the silica nanospheres with an ordered pore structure prepared in Examples 1 and 2, respectively, after degassing treatment at 150 degrees Celsius, in nitrogen adsorption-degassing Attached analyzer (Quantachrome NOVA 4200e, Quanta, USA) to measure its nitrogen adsorption characteristics at -196 degrees Celsius. See the experimental results image 3 The middle curve shows that the porous silica nanospheres with a special surface structure and the silica nanospheres with an ordered pore structure have good gas adsorption properties. image 3 a. image 3 c is the nitrogen adsorption-desorption isotherm and pore size distribution curve of porous silica nanospheres with a special surface structure; image 3 b. image 3 d is the nitrogen adsorption-desorption isotherm and pore size distribution curve of ordered porous silica nanospheres with special surface structure. image 3 a. image 3 b sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| D value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com