Steel grid wall

A technology of steel grids and grid sheets, applied in the field of steel grid walls, can solve the problems of increased cost of wall panels, high rigidity, poor rigidity and load-bearing performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

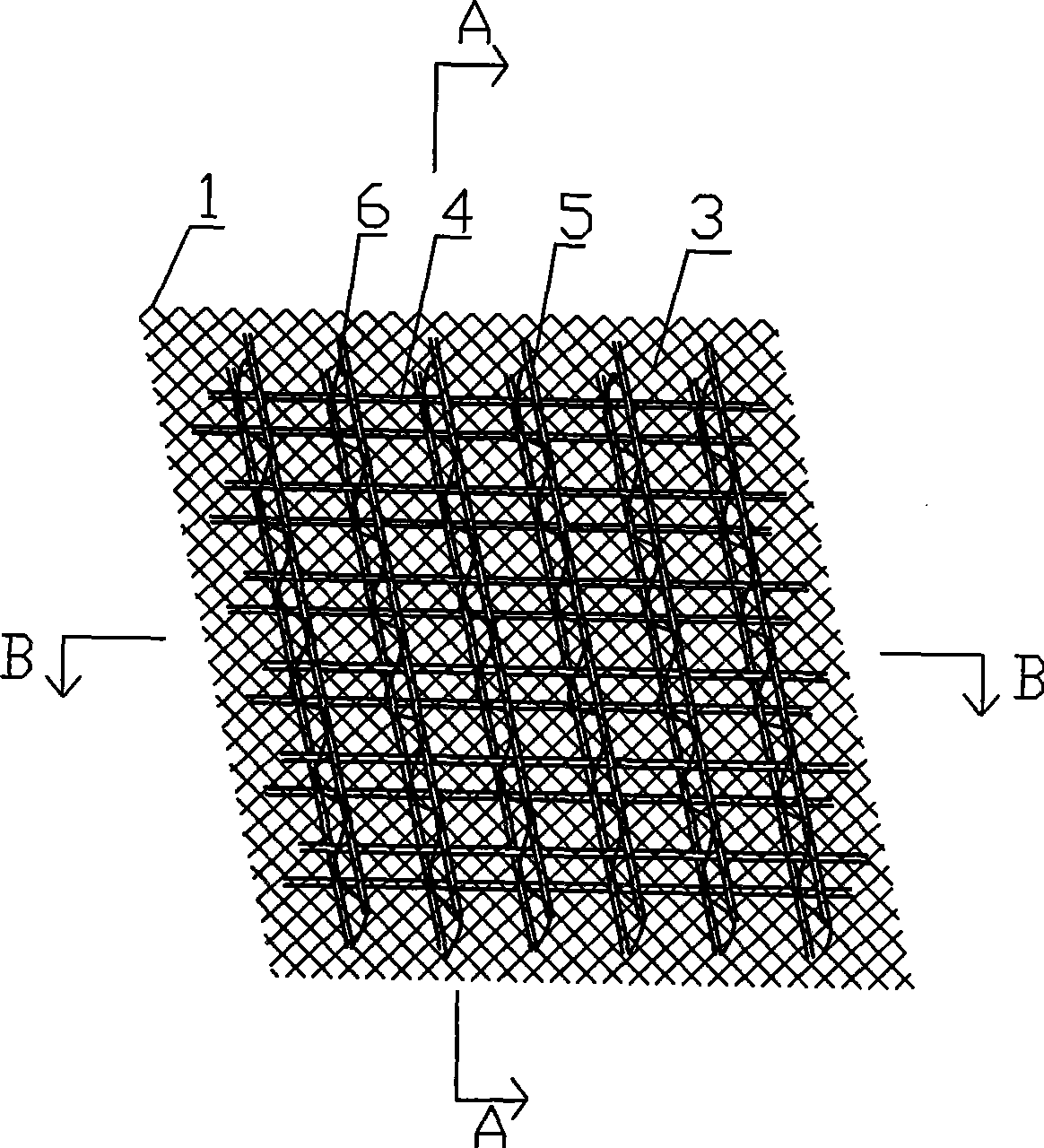

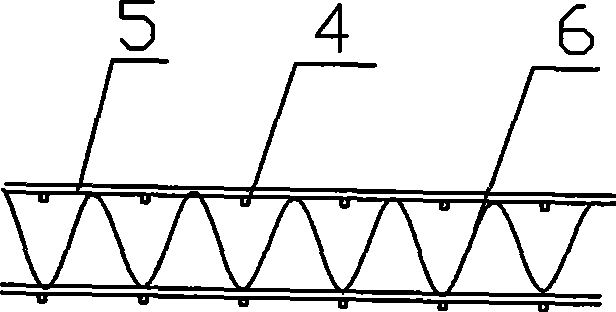

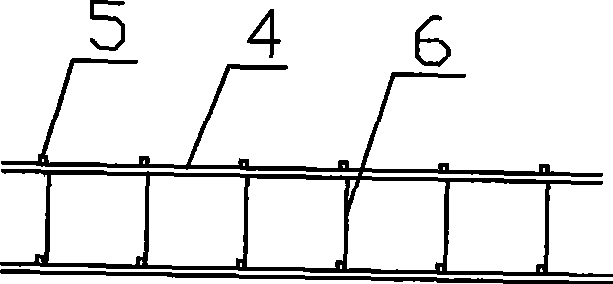

Embodiment 1

[0020] The steel grid wall of the present invention is composed of a wall panel unit 1 and a female column 2. The wall panel unit 1 is composed of a grid sheet 3, a transverse rib 4, a longitudinal rib 5, and a W-shaped steel bar 6. The frame formed by welding the transverse ribs 4 and the longitudinal ribs 5 is covered with grid sheets 3 respectively. The four peripheries of the two grid sheets are connected around the frame, and the interlayer between the two frames is fixedly connected with W-shaped steel bars 6, The W-shaped steel bars 6 are arranged in parallel in the same direction. The female column 2 is composed of two parallel steel pipes 7 and steel bars 9. The steel bars 9 are located in the middle of the two steel pipes 7, and the steel pipes and the steel bars are connected by the W-shaped steel bars 9 into a whole, and the steel grid The wall is formed by lashing and splicing the two sides of the wall panel unit 1 with expansion sleeves and the female column 2. The s...

Embodiment 2

[0022] The said steel grid wall is formed by tying and splicing steel strips with clamping slots on both sides of the wall panel unit 1 and the female column 2, and the rest is the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com