Mechanical energy storage battery

An energy storage battery, mechanical technology, applied in the direction of controlling mechanical energy, mechanical equipment, electromechanical devices, etc., can solve the problems of chemical battery pollution, no practical value, consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

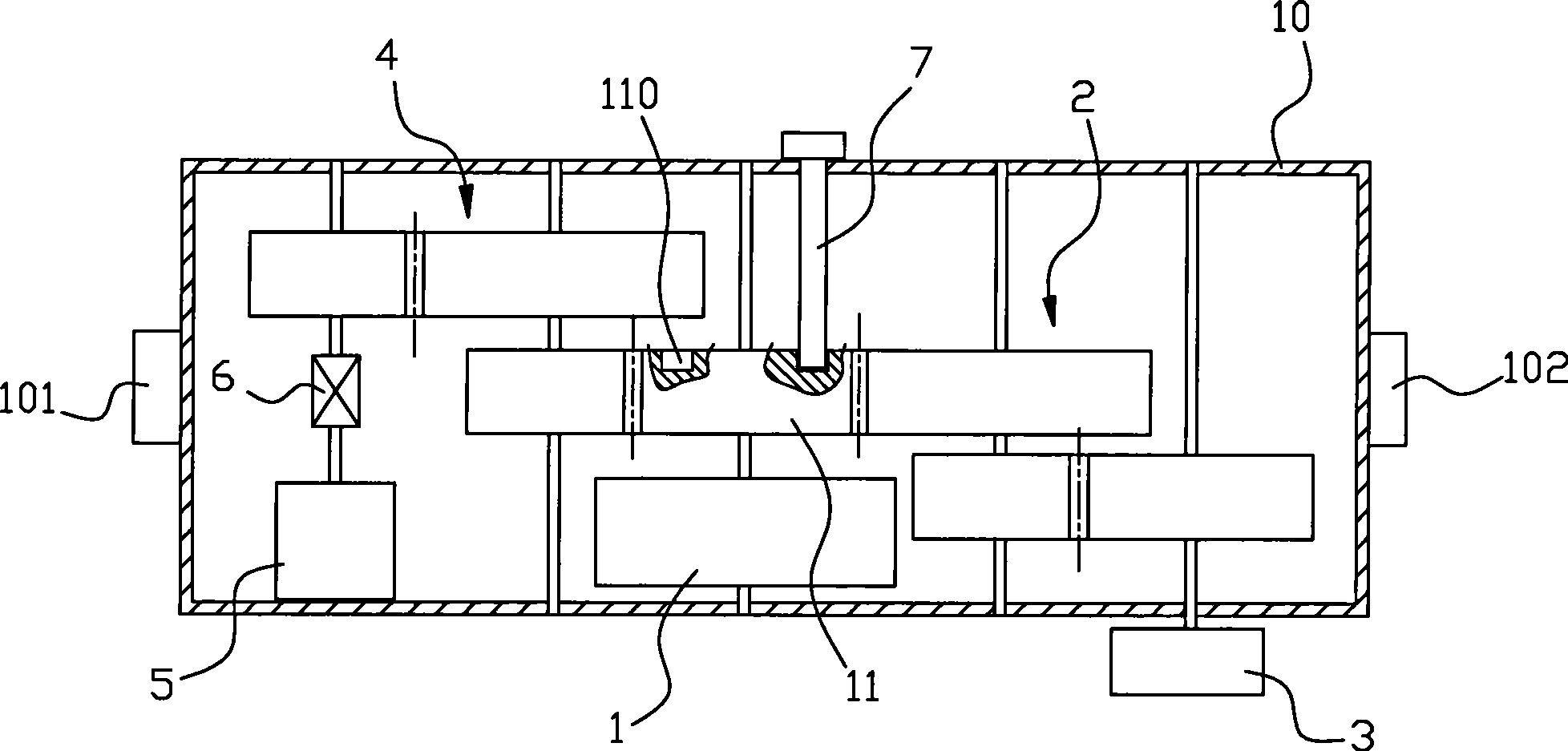

[0018] refer to figure 1 , a mechanical energy storage battery, the main structure includes a spring energy storage device 1 , a deformation drive device 3 , a permanent magnet generator 5 and a casing 10 . The spring energy storage device 1 includes a spring that can store mechanical energy through deformation. The spring has a deformation-driven release end 11. The deformation-driven release end 11 is used to drive the spring to deform by an external force, and the recovery of the spring deformation is also driven by the deformation. The release end 11 is released. The deformation driving device 3 is connected with the deformation driving release end 11 of the spring of the spring energy storage device 1 through a first transmission device 2 . The rotor of the permanent magnet generator 5 is connected to the deformation drive release end 11 of the spring of the above-mentioned spring energy storage device 1 through a second transmission device 4, and its electric output end...

specific Embodiment 2

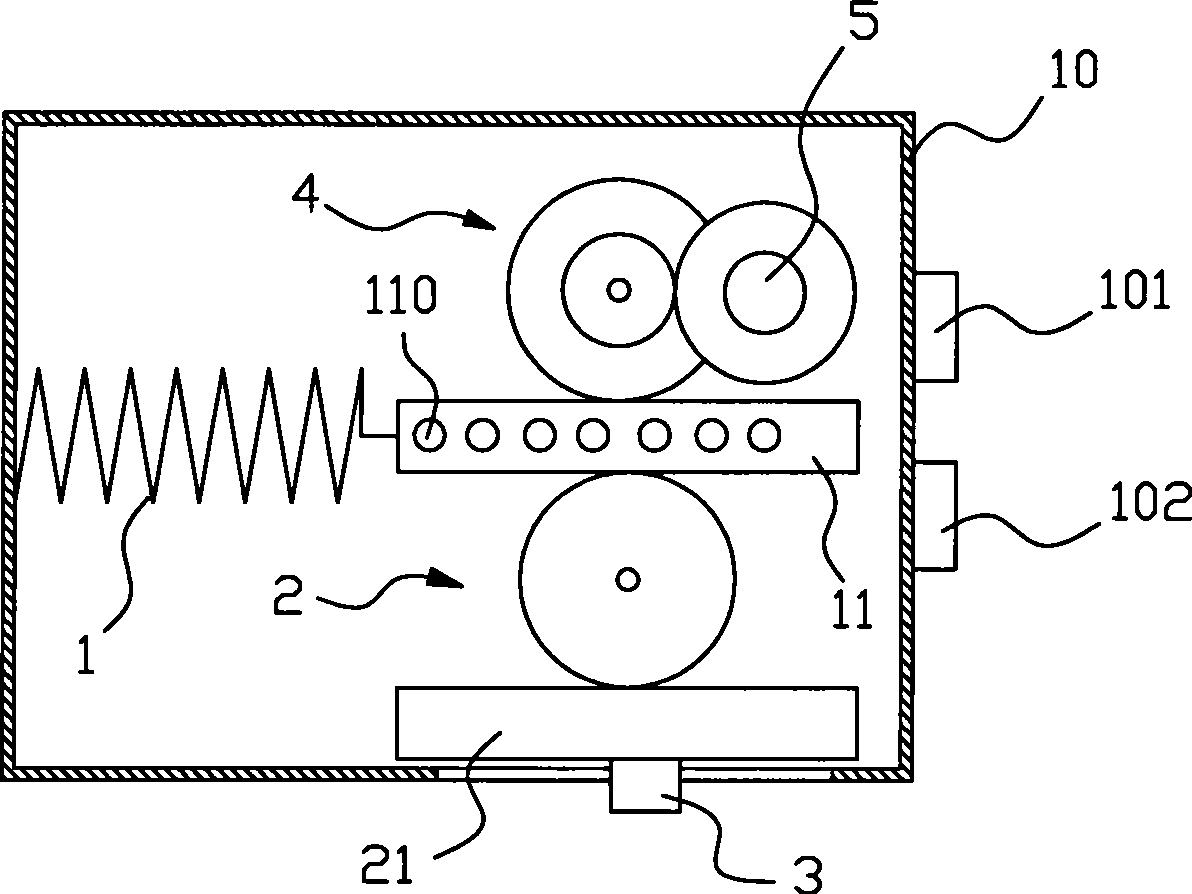

[0024] The structure of this embodiment is basically the same as that of Embodiment 1, the main difference is that the deformation driving device 3 is a slider slidingly arranged on the housing 10, the first transmission device 2 is a rack and pinion rotating device, The slider is connected with the rack of the first transmission device 2 . That is to say, an external force acts on the slider to make it move in a straight line, which is converted into rotation of the spring in the spring energy storage device 1 through the rack and pinion transmission. On the contrary, during the spring reset process in the spring energy storage device 1 , the slider will be driven to move linearly in the opposite direction.

specific Embodiment 3

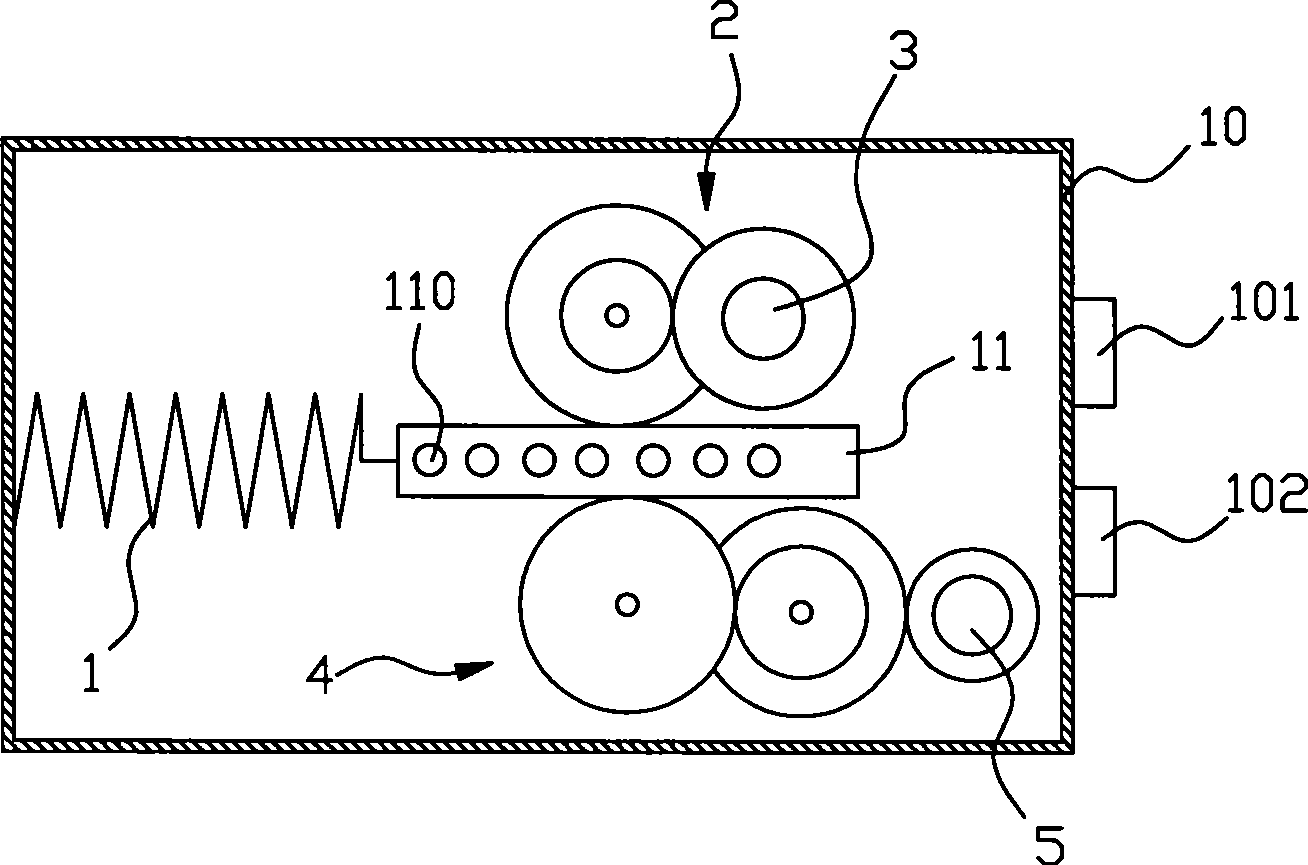

[0025] refer to figure 2 , a mechanical energy storage battery, the main structure includes a spring energy storage device 1 , a deformation drive device 3 , a permanent magnet generator 5 and a casing 10 . The spring energy storage device 1 includes a spring that can store mechanical energy through deformation. The spring has a deformation-driven release end 11. The deformation-driven release end 11 is used to drive the spring to deform by an external force, and the recovery of the spring deformation is also driven by the deformation. The release end 11 is released. The deformation driving device 3 is connected with the deformation driving release end 11 of the spring of the spring energy storage device 1 through a first transmission device 2 . The rotor of the permanent magnet generator 5 is connected to the deformation drive release end 11 of the spring of the above-mentioned spring energy storage device 1 through a second transmission device 4, and its electric output en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com