Solid interface contact heat exchange coefficient measurement method and apparatus based on transient method

A heat transfer coefficient measurement and solid interface technology, applied in the direction of material thermal conductivity, material thermal development, etc., can solve the problems of insufficient temperature acquisition and data processing methods, low temperature, and insufficient experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

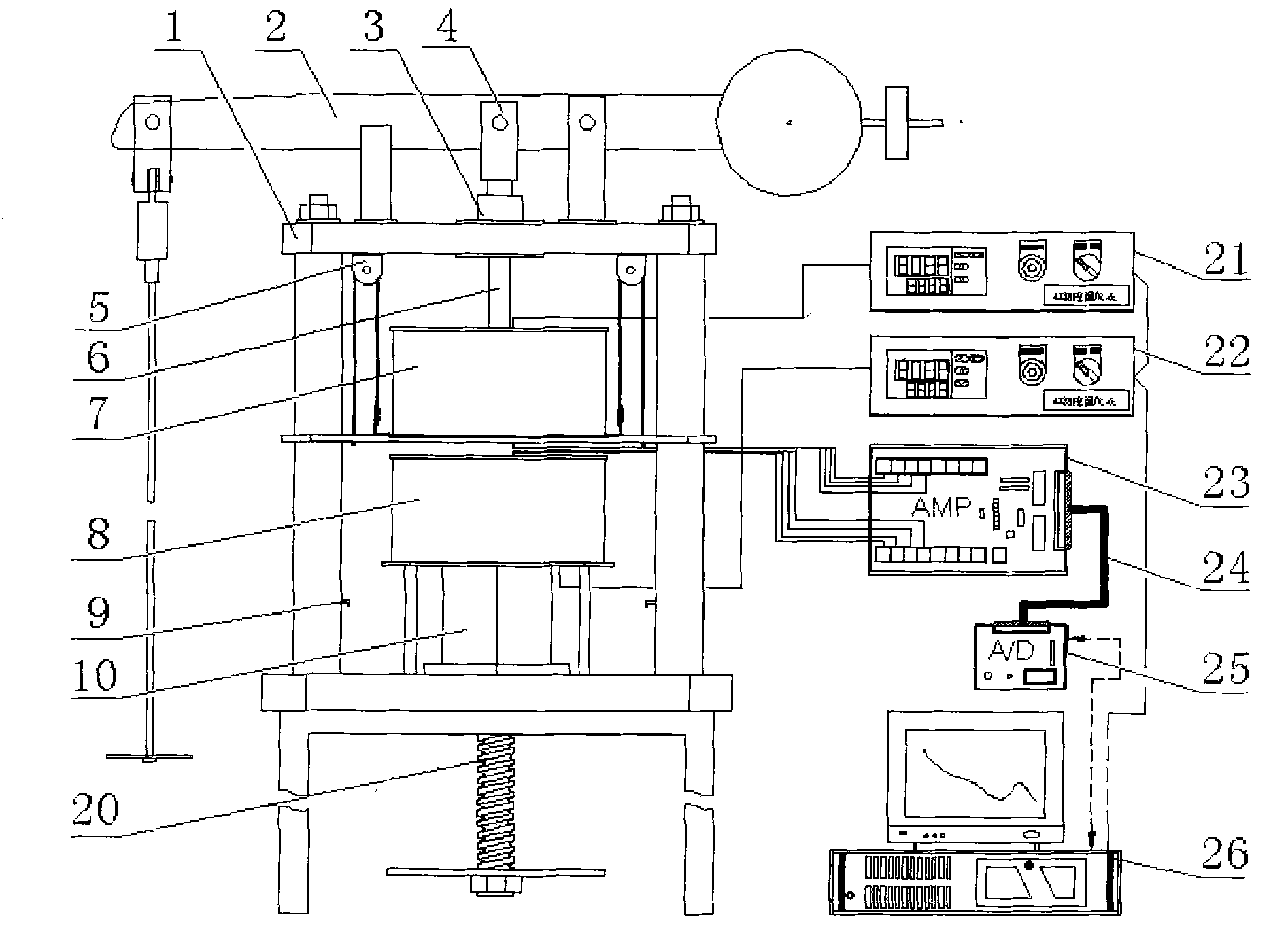

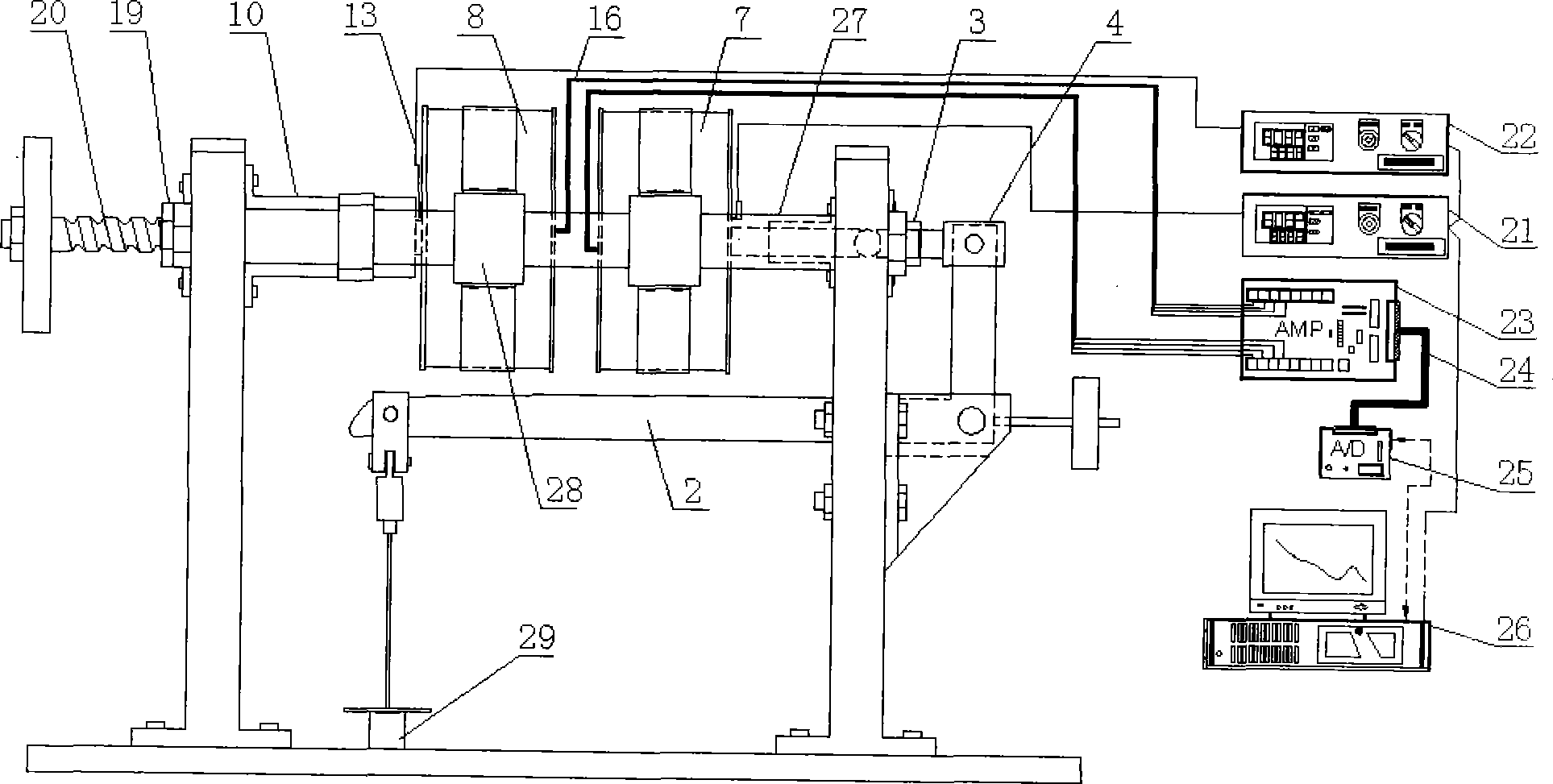

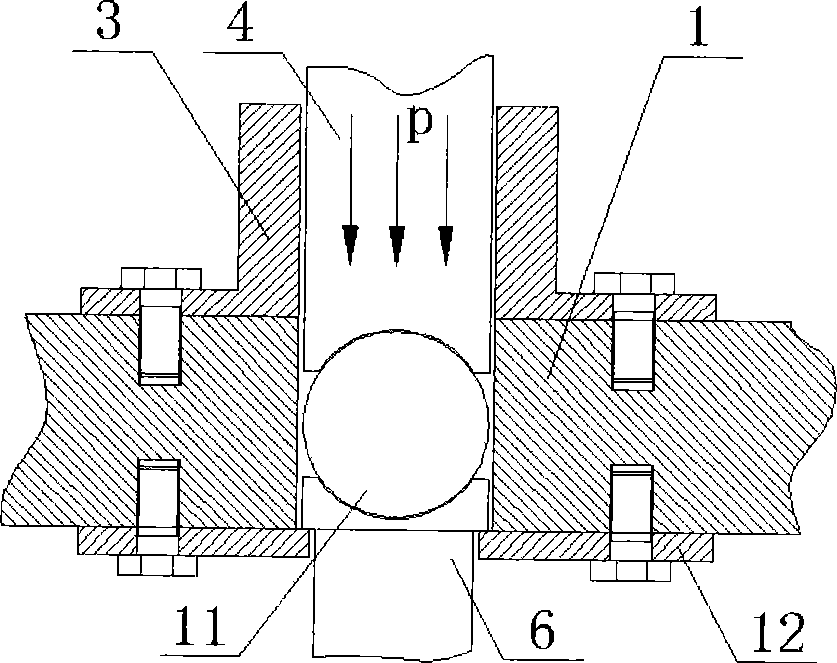

[0032] The material of low-temperature sample 14 is K403 cast superalloy, the material of high-temperature sample 15 is TC11 titanium alloy, and the pre-contact surface of the sample is 400 # Grind with sandpaper to make the surface roughness basically the same. When the device is a vertical structure, since the pressure changer joint 4 is connected with the lever loading device 2, the fulcrum of the pressure changer joint 4 and the gravity direction of the weight in the lever loader 2 The force arm ratio is 1:5, therefore, after adding five 10Kg weights to the weight plate of the lever loading device 2, the maximum pressure on the contact surface of the sample can reach 2450N, and the positioning block part of the lever loading device 2 bears the pressure in advance , to keep the lever balanced, and the downward pressure produced by the pressure knuckle 4 is zero at this time. The fixed pulley mechanism 5 is fixed on the lower surface of the upper support plate 1, including t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com