Method and device for the continuous plasma treatment of materials, in particular for the descaling of a metal strand

A plasma and plasma reactor technology, applied in the field of processing materials, can solve problems such as increasing the demand for lubricants, unable to completely remove the oxide layer, etc., and achieve the effects of reducing the number of processing steps, avoiding material loss, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

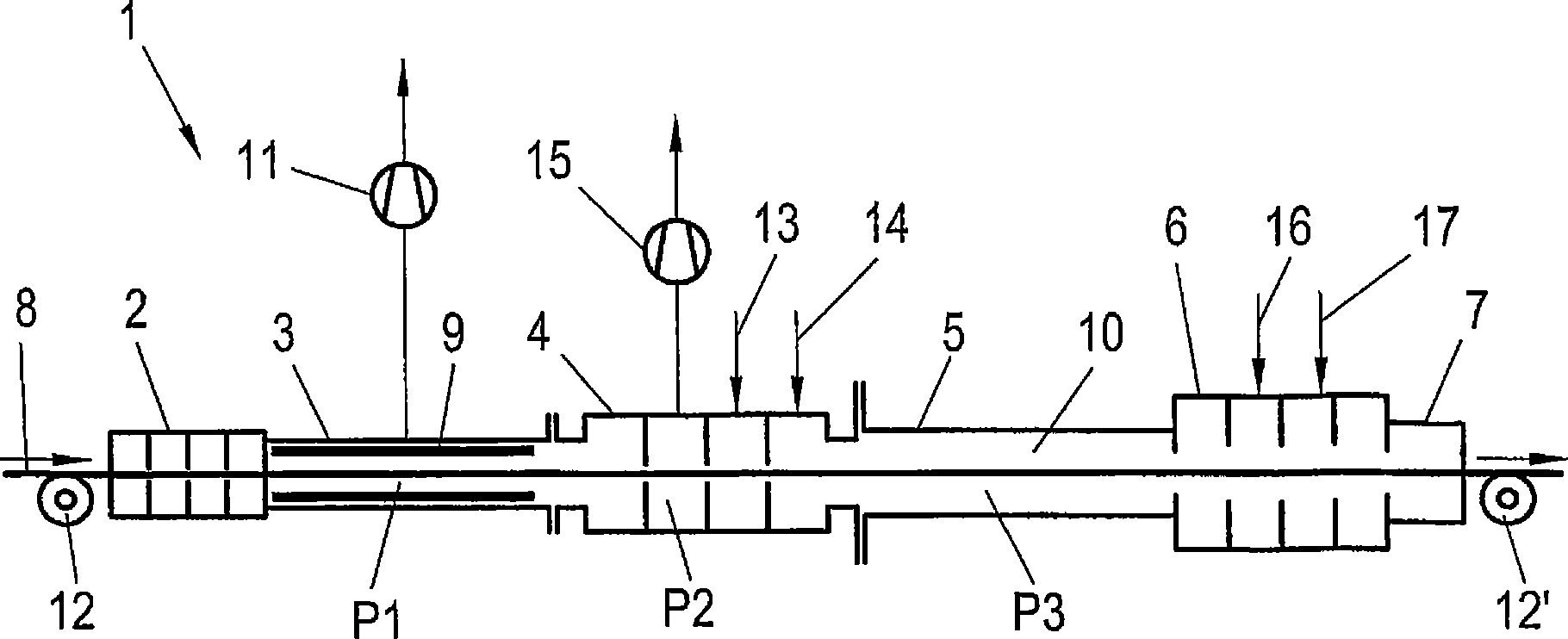

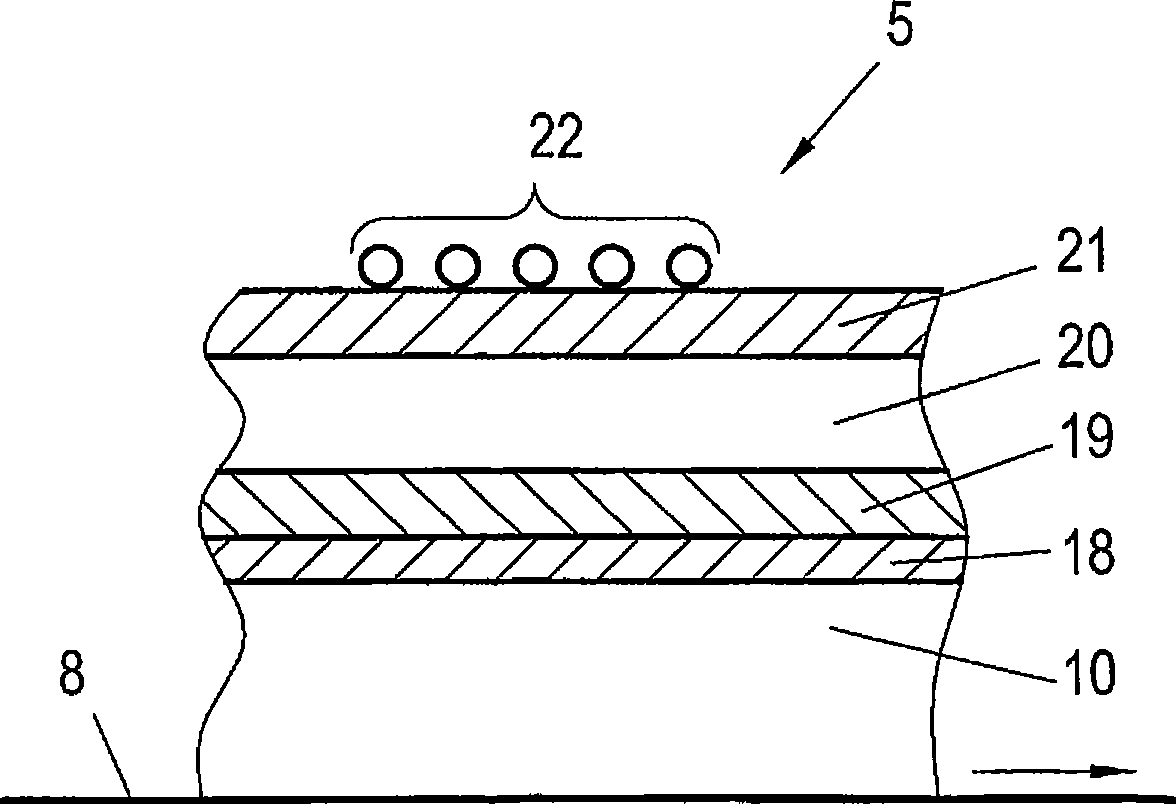

[0027] figure 1 In , an embodiment of a device 1 according to the invention is schematically shown, which is particularly suitable for the treatment of continuous - eg wires, rods, pipes etc. - material 8 . The continuous material enters the heating chamber 3 through the gate 2, and the material is heated to at least 100°C by the heating device 9 when passing through the heating chamber 4, so that most of the pollutants on the surface of the material 8, such as scale, are peeled off due to heating . A pressure P1 of between 0.1 and 10 mbar is generated in the heating chamber 3 by a vacuum pump 11 . In this embodiment, the heating chamber 3 has a coaxial geometry, wherein the heating device 9 is a plasma heater with an external electrode as an anode, which is arranged in the heating chamber 3 and is covered with a continuous material. The continuous material 8 forms an internal electrode, which is brought to zero potential via conductive rollers 12, 12' and thus serves as a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com