Linear drive and linear compressor with adaptable output

A linear drive, linear compressor technology, applied in the direction of the engine without a rotating main shaft, the engine element, the variable capacity engine, etc., can solve the problems of increasing the required parts and spare parts spectrum, high cost, complex design, etc. The effect of efficient and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

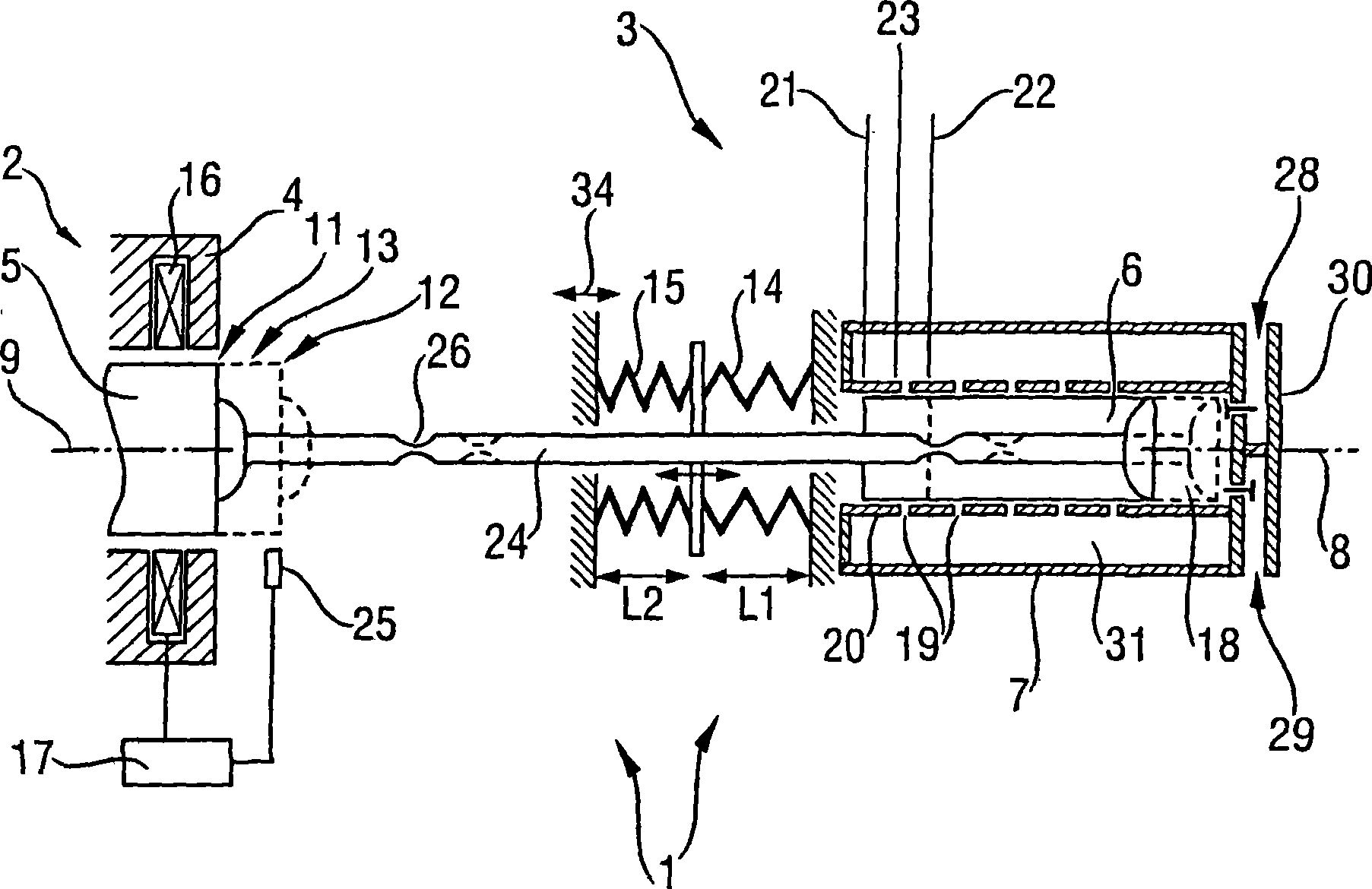

[0056] figure 1 A sectional view of a device 1 according to the invention is shown with a linear drive 2 and a linear compressor 3 . The linear drive 2 has a stator 4 , wherein a rotor 5 moves in a reciprocating manner along a drive axis 9 . The rotor 5 is driven by means of drive coils 16 which are supplied with drive coil current by means 17 for actuating the drive coils 16 .

[0057] The rotor 5 oscillates between a first rotor reversal point 11 and a second rotor reversal point 12 and in doing so passes through a rotor zero position 13 . The movement of the rotor 5 is sensed by means of a position sensor 25 which transmits position information to the means 17 for actuating the drive coils 16 , as a result of which a control system is implemented for the movement of the rotor 5 as a whole.

[0058] The linear compressor 3 has a piston housing 7 in which the compressor piston 6 oscillates in a reciprocating manner along the piston axis 8 between a first piston reversing po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com