A bag dust collector and its manufacturing method

A technology of bag dust collector and manufacturing method, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of insufficient purification effect, increase the frequency of back blowing, and low recovery efficiency, so as to improve the adsorption performance and purification effect, the chance of avoiding direct contact, and the effect of avoiding direct washing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

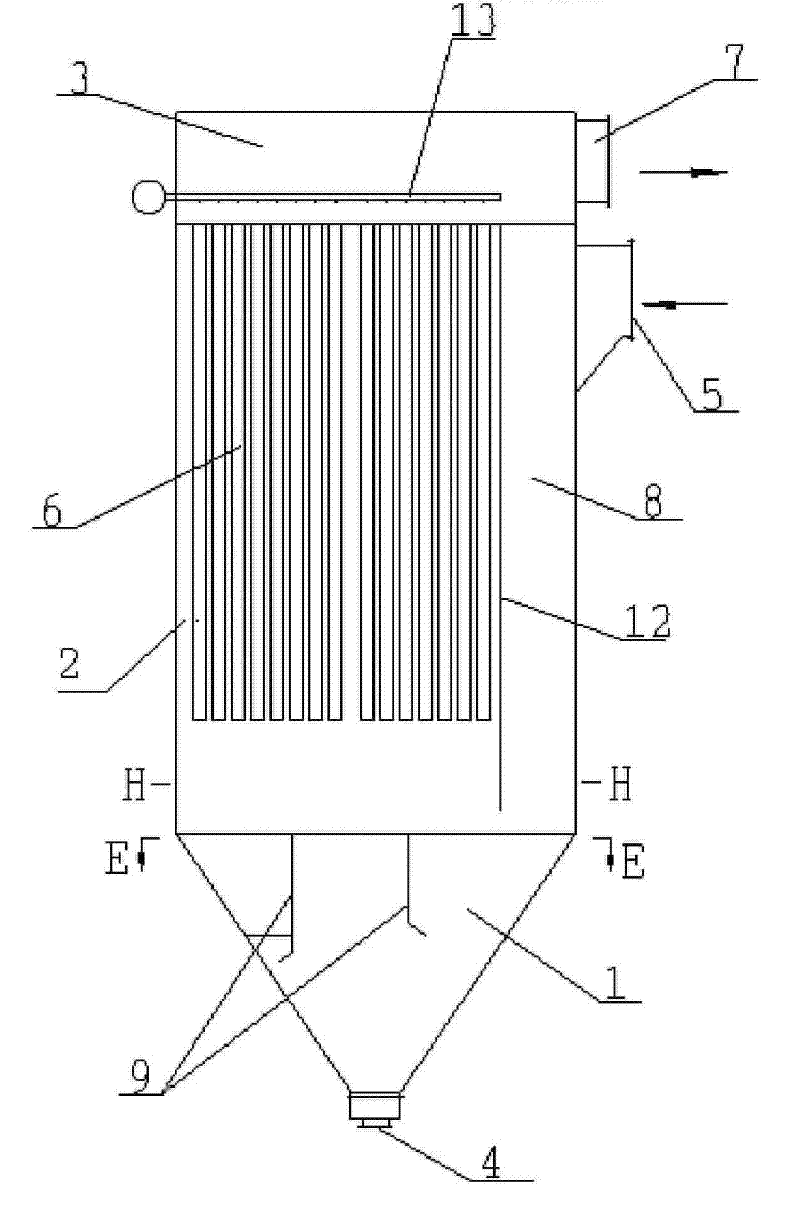

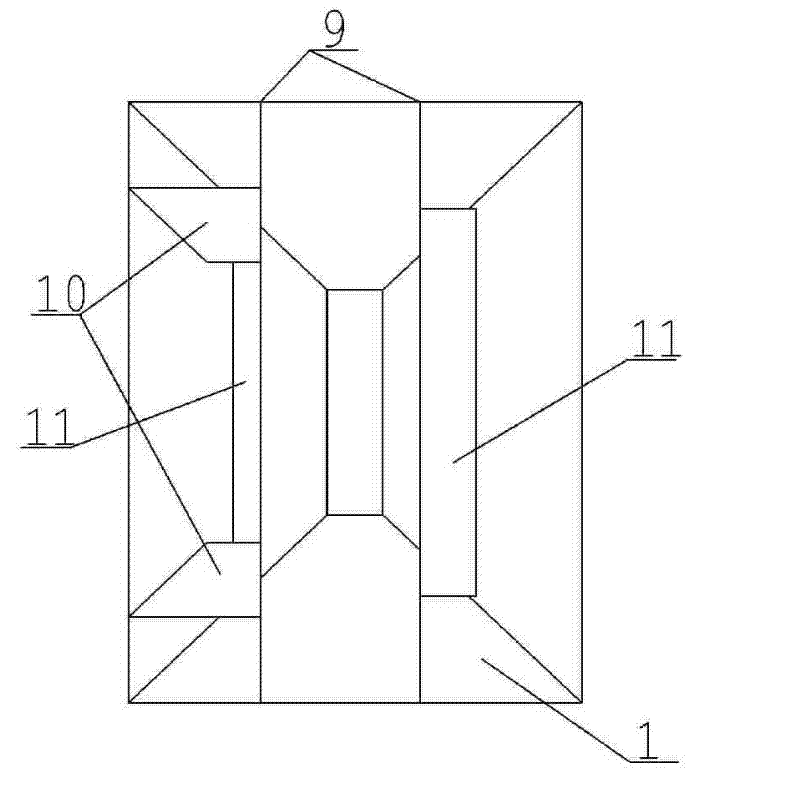

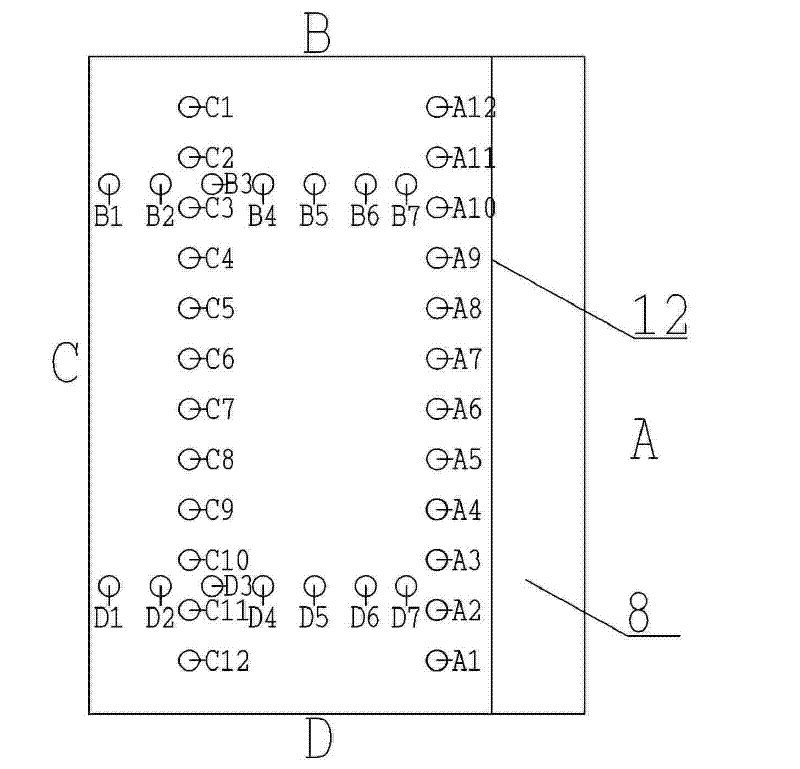

[0027] Embodiments of the present invention: the structure of the present invention is as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, it is composed of an existing bag filter connected with an ash hopper 1, a middle box 2 and an upper box 3 in sequence and is restructured. An ash discharge port 4 is installed at the lower end of the ash hopper 1, and an ash discharge port 4 is installed in the middle box. 2 is connected with an air inlet 5, in which a filter bag 6 is suspended, and a gas outlet 7 and a blowback system 13 are installed on the upper box body 3. When making the present invention, one side in the middle box body 2 An air flow passage 8 communicating with the air inlet 5 is provided, which can be formed by welding a partition 12 parallel to the box panel (side A) connected to the air inlet 5 in the middle box, and welded After the dividing plate 12 is finished, the opening of the air flow passage 8 formed is opposite to the opening of the ash hoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com