Hydrodynamic auxiliary shoring cutter-holder and shoring method

A technology of hydrodynamic pressure and auxiliary support, applied in the direction of reamer, boring bar, tool holder accessories, etc., can solve the problem of high installation and adjustment requirements of support bars or support blocks, unsatisfactory support effect, and high manufacturing and use costs. problem, to achieve good effect of absorbing tool vibration, increasing rigidity and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

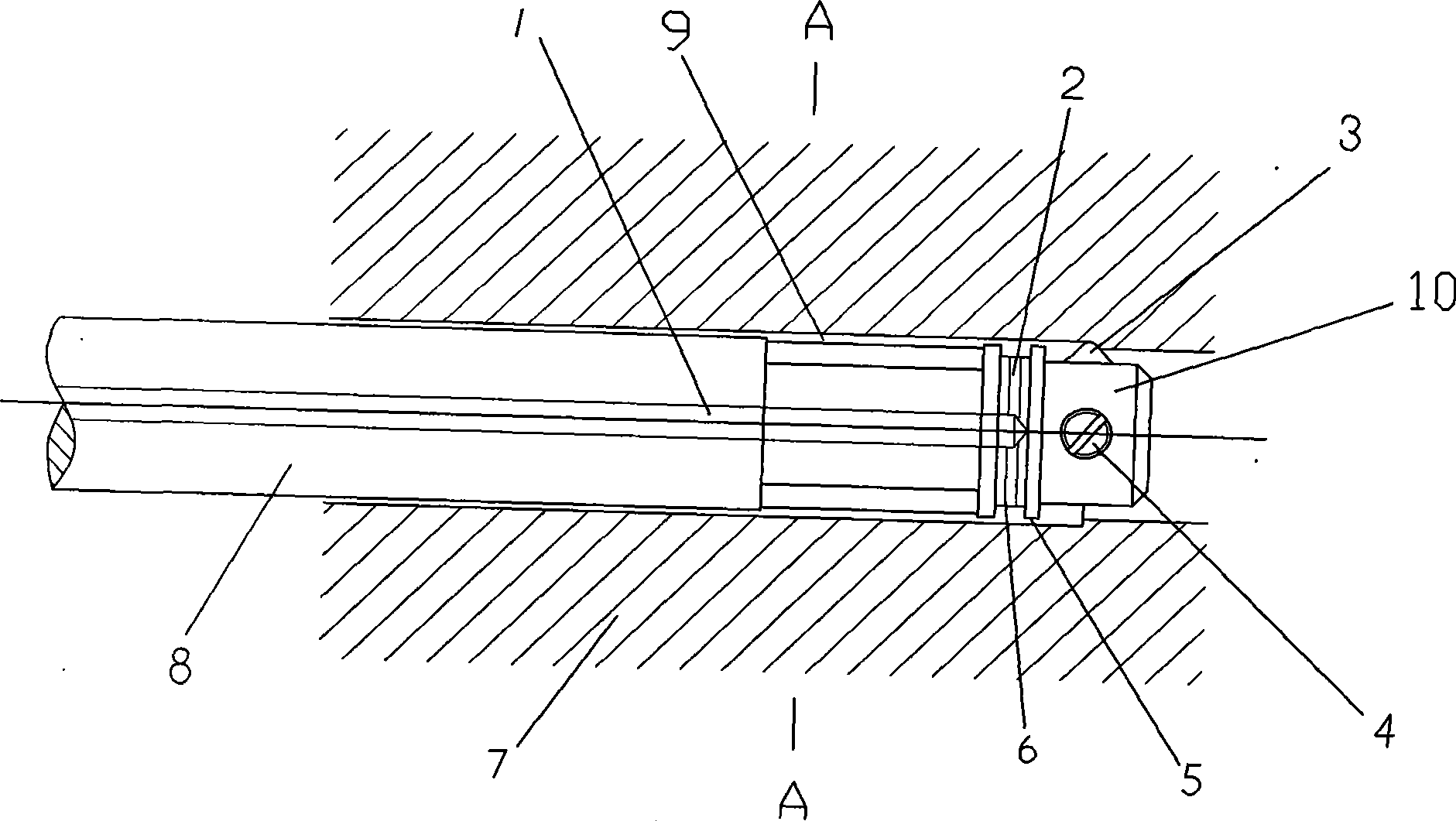

[0014] see figure 1 In this embodiment, the hydrodynamic auxiliary support tool bar has a bar head 10 for installing a tool, a hosel for arranging the cutting fluid flow channel 2, and a shaft 8 as a support for the bar head, and the central axial hole of the shaft 8 is set It is the cutting fluid supply channel 1, and the liquid supply channel 1 is connected with the hosel cutting fluid flow channel 2.

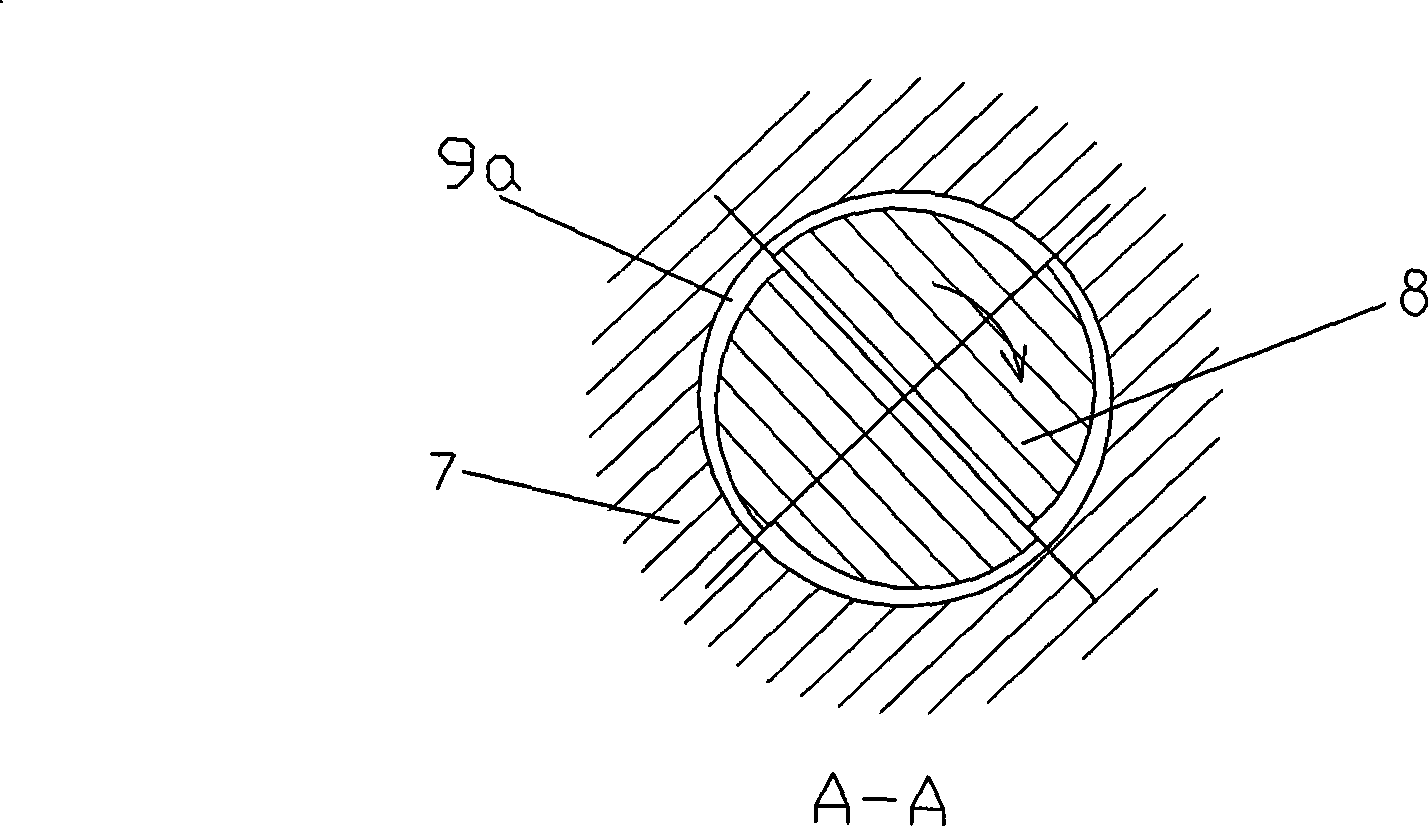

[0015] In this example, if figure 1 As shown, a section of pressure-bearing groove 9 is set at the front end of shaft 8, such as figure 2 As shown, the cross-section of the pressure-bearing groove 9 is a wedge-shaped groove 9a arranged in segments along the circumference. The wedge-shaped groove 9a takes the deep groove end as the groove head, takes the shallow groove end as the groove tail, and transitions with a circular arc in between. The head of the intermediate groove is connected with the tail of the groove, and the liquid supply channel 1 communicates with the wedg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com