Three-gear manual rotating tool

A screwdriver and handle technology, which is applied in the field of three-speed manual screwdrivers, can solve the problems of losing the reliability of the combination of the clutch and the handle, making it difficult to ensure the swing of the knife body, and affecting the cooperation of the positive and negative pawls, so as to prevent swinging and swinging The effect of reducing shaking and facilitating restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

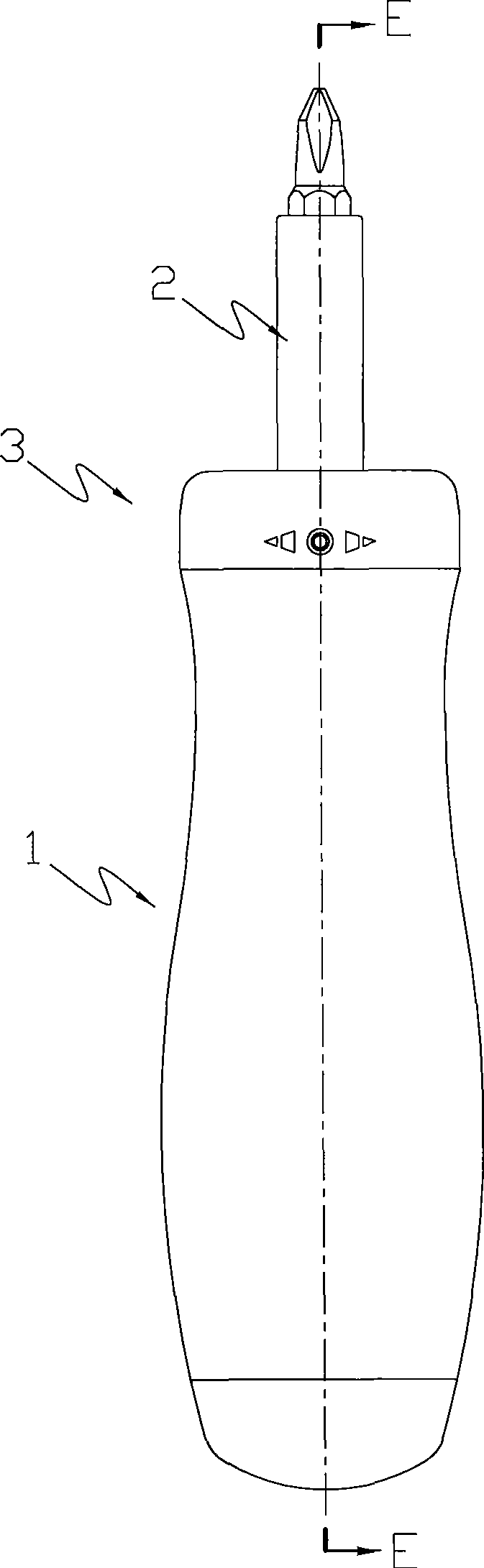

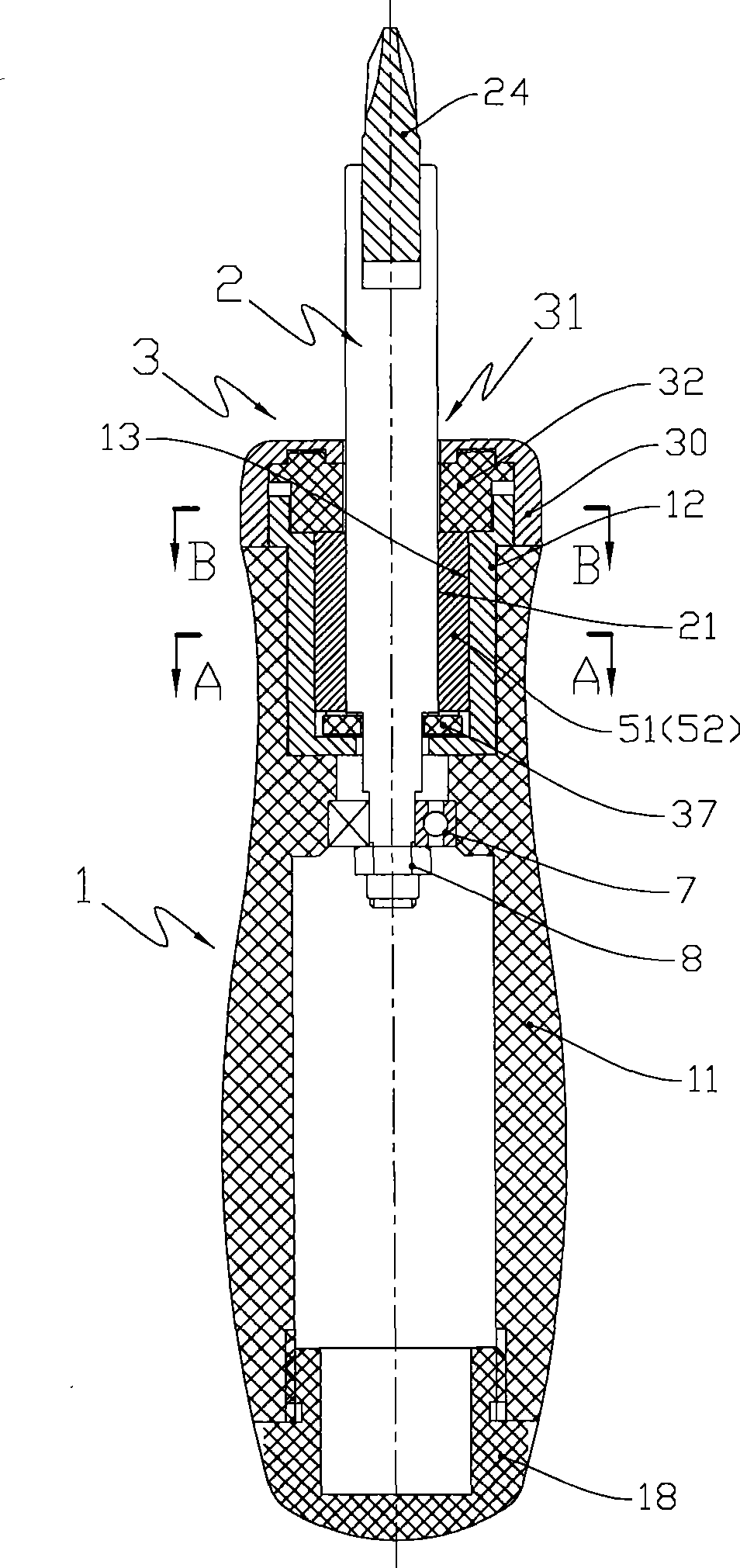

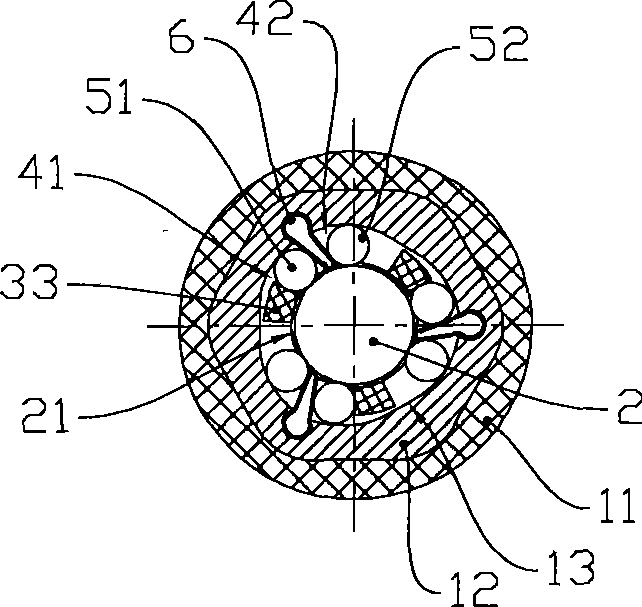

[0060] Such as figure 1 , 2 , 3A, 3B, 3C, 4A, 4B, 4C shown in the three-speed manual screwdriver, which is assembled by the handle 1, the working rod 2, the gear changer 3, the roller and other parts, as the present invention A preferred embodiment, the following describes the structure of each component and its assembly relationship and mutual action cooperation to illustrate the concept of the present invention:

[0061] The main part of the handle 1 is a plastic grip. In order to have a strong resistance to extrusion and deformation in order to transmit torque, a reinforcement kit 12 is embedded on it. Figure 3A , 3B As shown in 3C, the inner wall of the reinforcement kit 12 is formed with a convex prism surface as the first working surface 13. The so-called convex prism surface means that the outer contour line of the cross section has no concave part; in order to achieve the third level of work, Three positioning grooves are provided on the cylindrical inner wall of the rei...

Embodiment 2

[0070] Referring to the first embodiment, the convex prism surface as the first working surface 13 and the cylindrical surface as the second working surface 21 are interchanged, that is, the convex prism surface is formed on the circumferential surface of the working rod, and the cylindrical surface is formed On the inner hole wall of the reinforcement kit, the function of the first embodiment can also be achieved, and it will not be repeated here and shown in drawings.

Embodiment 3

[0072] Such as Figure 5 , 6 , 7A, 7B, 7C, 8A, 8B, 8C shown in the three-speed manual screwdriver, which is assembled by the handle 1, the working rod 2, the gear changer 3, the roller and other parts, as the present invention A preferred embodiment, the following describes the structure of each component and its assembly relationship and mutual action cooperation to illustrate the concept of the present invention:

[0073] The main part of the handle 1 is a plastic holding member 11. In order to have a strong resistance to extrusion and deformation in order to transmit torque, a reinforcing column 19 is embedded on it, from Figure 7A , 7B 7. As shown in 7C, the outer surface of the reinforcing column 19 forms a convex prism surface as the first working surface 13. The so-called convex prism surface means that the outer contour line of the cross section has no concave part; Figure 7A , 7B As shown in 7C, in order to achieve the third gear, the positioning pin 110 and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com