Construction method of prestressed anchor rod static pressure pile

A technology of anchor static pressure pile and construction method, applied in sheet pile wall, foundation structure engineering, foundation structure repair and other directions, can solve the problems of low pile foundation performance, limited effect of foundation settlement and deformation control, etc. , The effect of saving the number of piles and reducing engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is further described, and this construction method is very clear to the people who are engaged in foundation or foundation reinforcement specialty.

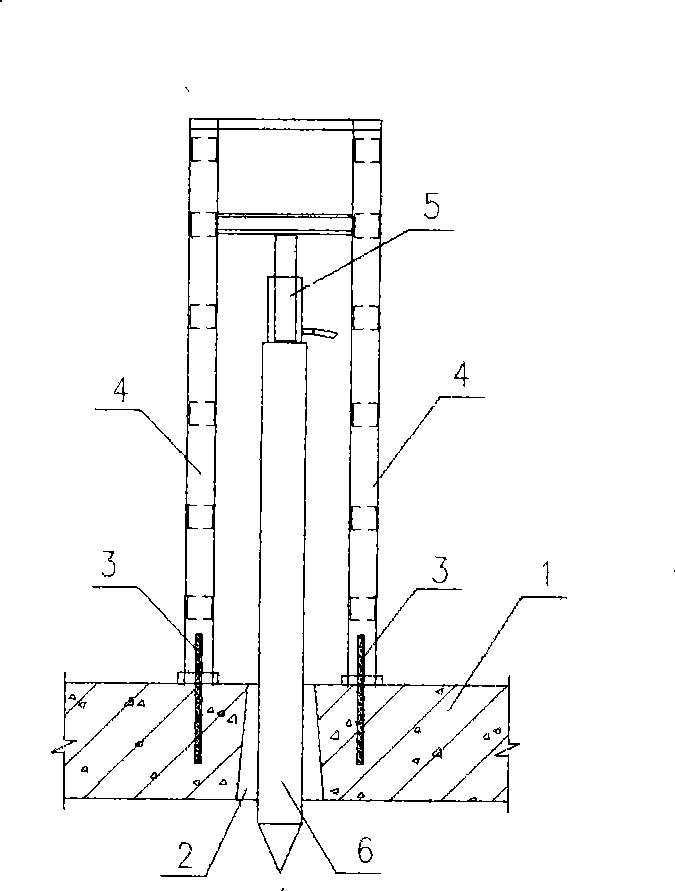

[0022] a. Press the pile (6) into the reinforced concrete foundation (1) as figure 1 :

[0023] Open the pile holes (2) on the reinforced concrete foundation (1) earlier, the pile holes (2) can also be reserved holes, the pile holes (2) should be small at the top and big at the bottom, and then the holes in the pile holes (2) Anchor rods (3) and pile frames (4) are buried around the periphery, and the piles (6) are pressed into the reinforced concrete foundation (1) section by section through a hydraulic jack (5). The piles (6) can be prefabricated piles or steel pipe piles, and the joints of piles are connected by welding or sulfur cement.

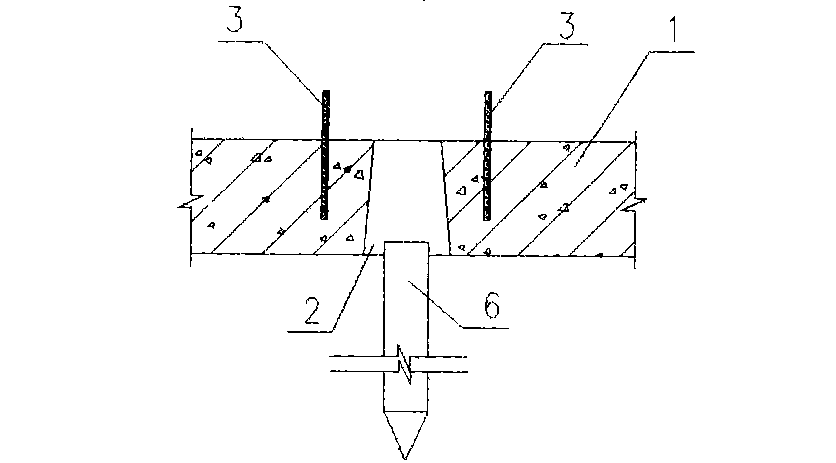

[0024] b. After the last section of pile is pressed, remove the pile frame, if figure 2 .

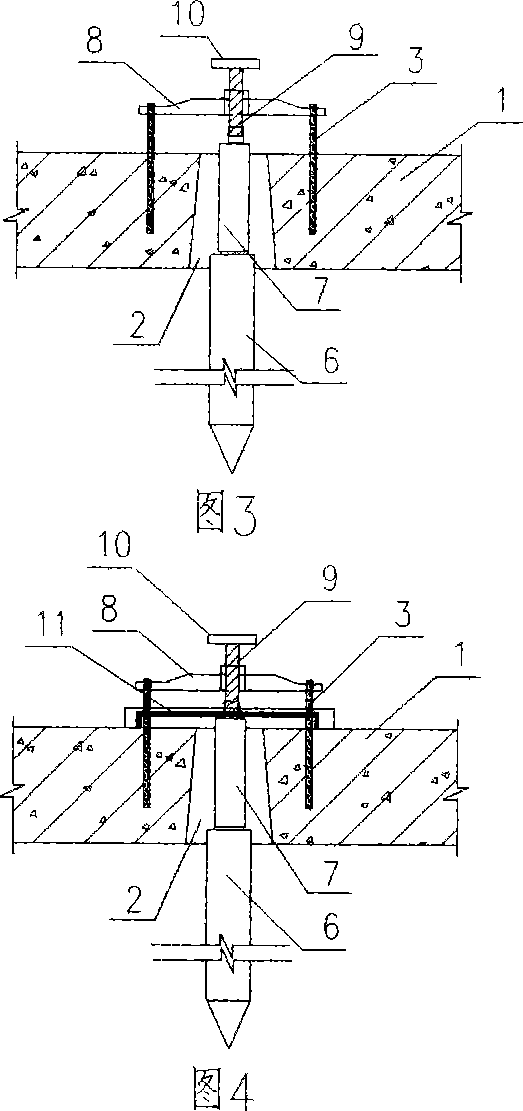

[0025] c. Apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com