Scaled refuse incineration drum grate

A technology of waste incineration and drum furnace, which is applied to incinerators, rotary grate, shaking grate, etc., can solve the problems of boilers not running normally, large frictional resistance, difficult to maintain, etc., achieve high practical value, solve the problem of stuck Astringent, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

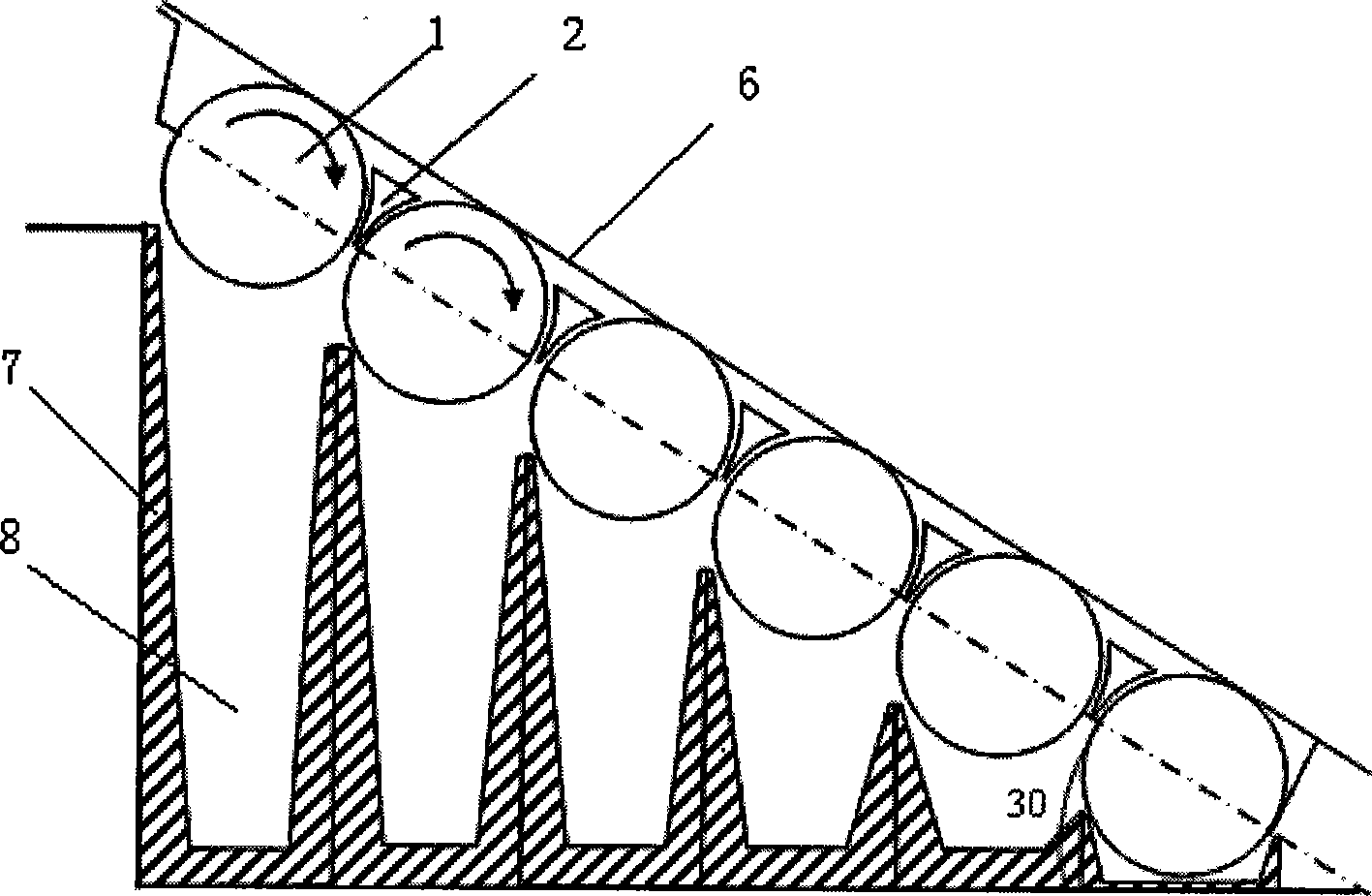

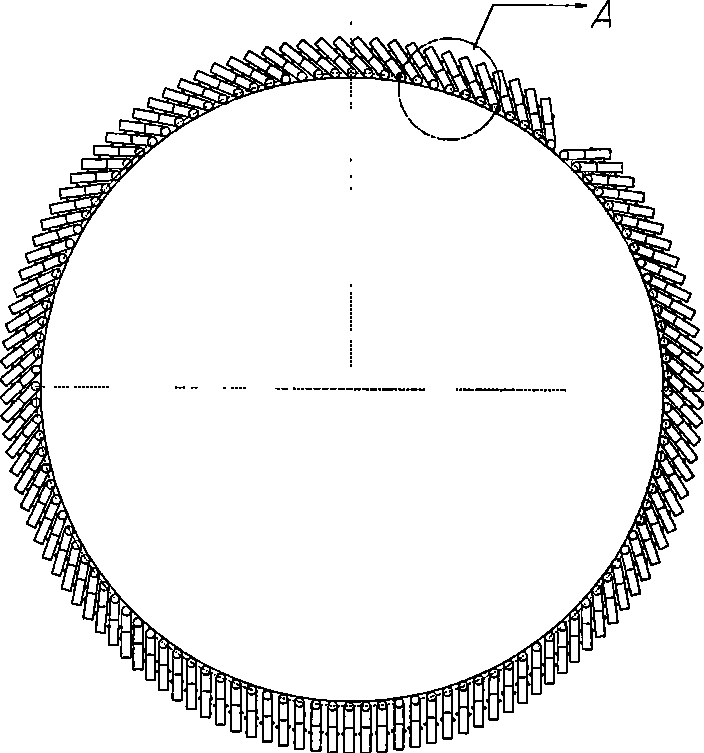

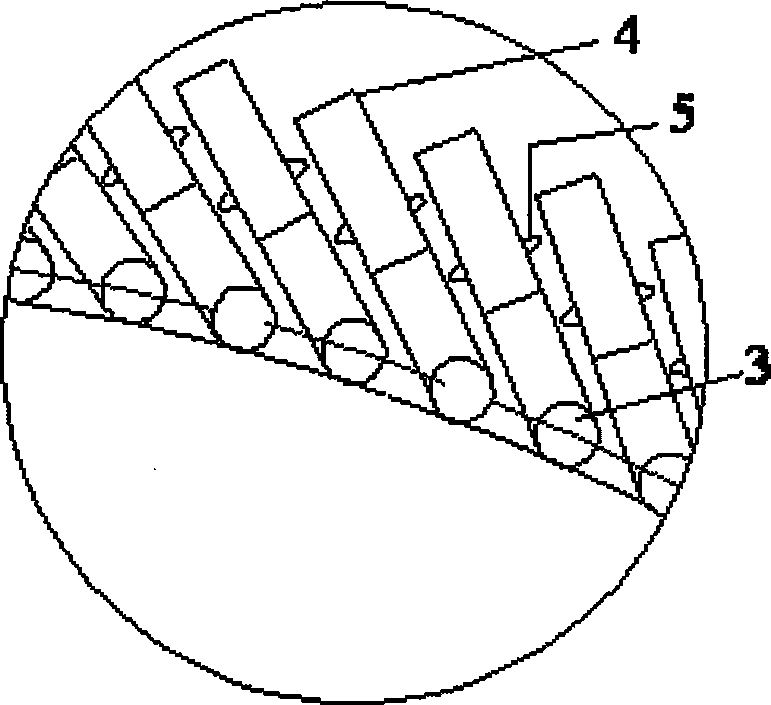

[0011] see figure 1 , the present invention comprises the fire grate surface 6 that is made of 3-10 drums 1, and general situation is advisable with 4-6, and the included angle of fire grate surface 6 and horizontal plane is 10-60 °, and the practical example selects 30 ° Included angle, each drum 1 is provided with an air outlet, and between adjacent drums 1, there is a slag stopper 2 for "shoveling" the garbage to the next drum 1. The slag stopper 2 is a hollow structure, and the middle is opened Cooling media such as air or water, the lower end of the slag stopper 2 is provided with a partition 7, which divides the space below each drum 1 into individual chambers, and each chamber is provided with a grate plate 4 for cleaning after rotation. Out of the funnel-shaped container 8 of the ash.

[0012] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com