Coke oven raw gas three-segment cooling method for supply hot water for heating and bathing

A three-stage cooling and raw gas technology, which is applied to heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of insufficient heat utilization and energy waste, and achieve low investment and good economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

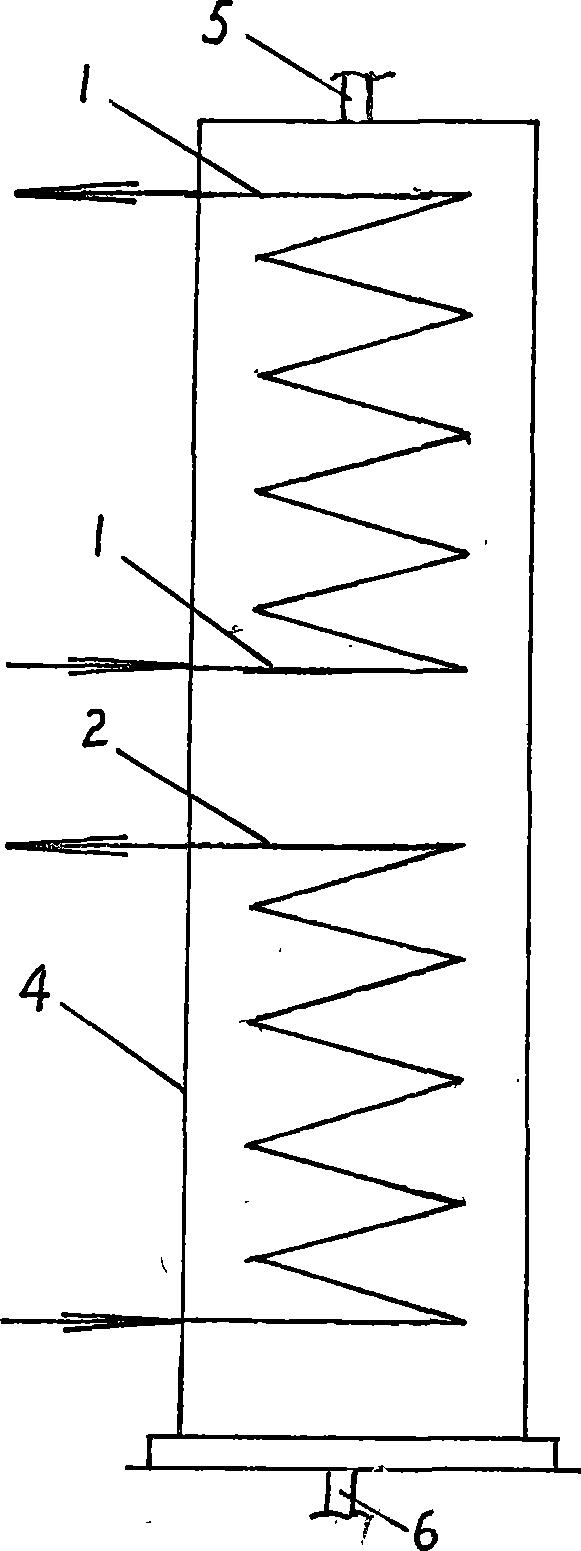

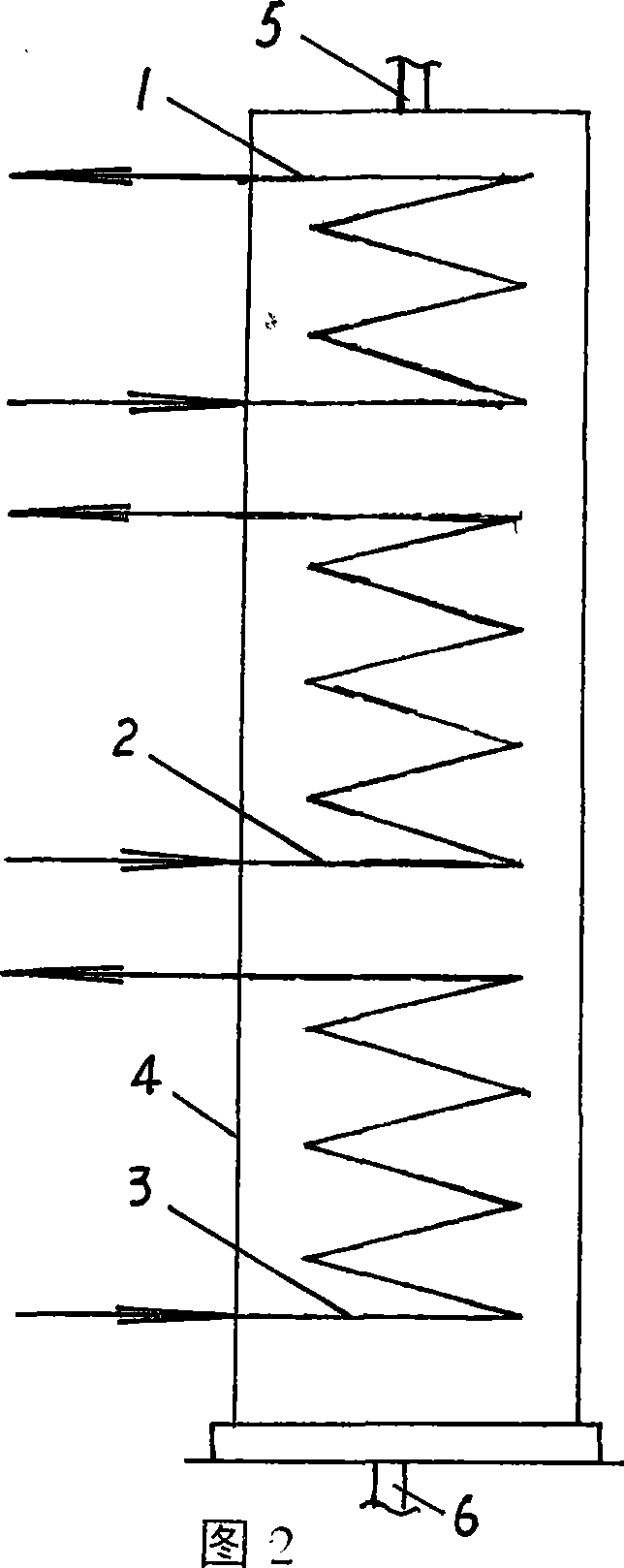

[0013] Example 1: The first stage uses 65℃ high temperature circulating water to cool the coal gas in the cooling pipe 1, the second stage uses 32℃ circulating water to cool the gas in the cooling pipe 2, and the third stage uses 18℃ low temperature water in the cooling pipe 3. Cooling gas, the second and third stages of heat exchange are the same as the existing process, so no further description. In the first stage, 65°C circulating water is used to reverse indirect heat exchange with the gas at 2.8m / s. The gas can be cooled to 68°C, while the circulating water is heated to 73°C. This will not only prevent the violent heat exchange from changing the temperature difference of the heat exchange tube Part of the circulating water that is large and deformed and heated to 73 is used for heating in the factory and the residents.

Embodiment 2

[0014] Example 2: The first stage uses 65℃ high temperature circulating water to cool the coal gas in the cooling pipe 1, the second stage uses 33℃ circulating water to cool the gas in the cooling pipe 2, and the third stage uses 19℃ low temperature water in the cooling pipe 3. Cooling gas, the second and third stages of heat exchange are the same as the existing process, so no further description. In the first stage, 65°C circulating water is used to reverse indirect heat exchange with the gas at 3.2m / s, so that the gas can be cooled to 70°C, and the circulating water can be heated to 75°C, which not only avoids the violent heat exchange causing the temperature difference of the heat exchange tube Part of the circulating water that is large and deformed and heated to 75°C is used for heating in the factory and heating of residents.

Embodiment 3

[0015] Example 3: The first stage uses 65℃ high temperature circulating water to cool the coal gas in the cooling pipe 1, the second stage uses 31℃ circulating water to cool the gas in the cooling pipe 2, and the third stage uses 17℃ low temperature water in the cooling pipe 3. Cooling gas, the second and third stages of heat exchange are the same as the existing process, so no further description. In the first stage, 65°C circulating water is used to reverse indirect heat exchange with gas at 3.0m / s, which can cool the gas to 69°C and the circulating water to 74°C, which not only avoids the violent heat exchange causing the temperature difference of the heat exchange tube Part of the circulating water, which is large and deformed and heated to 74°C, is used for heating in the factory and the residents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com