Instrument for measuring thickness of non-ferromagnetic material and surface coating of ironwork

A non-ferromagnetic, surface coating technology used in electrical/magnetic thickness measurement, electromagnetic measurement devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

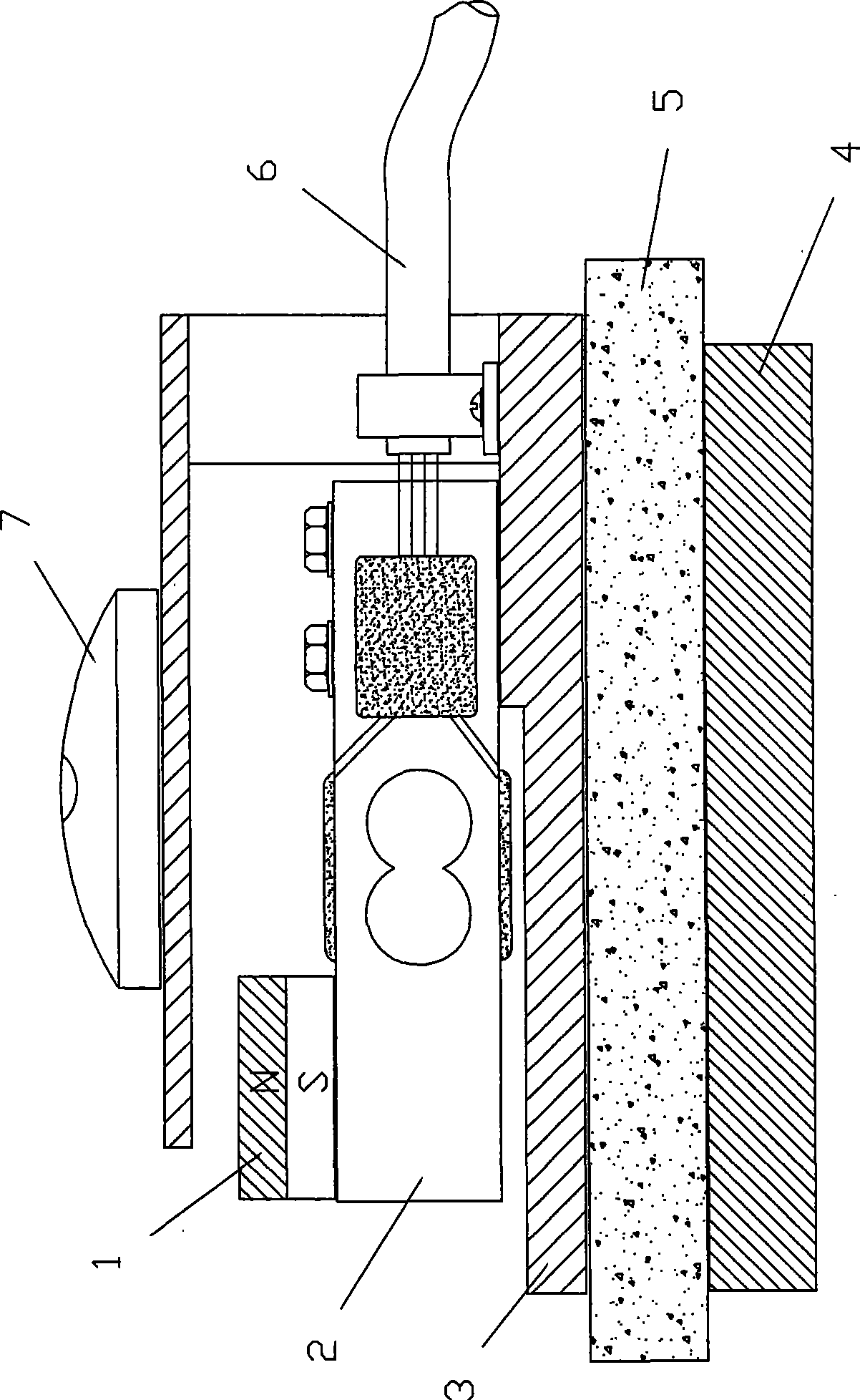

[0011] Embodiment comprises three parts of probe, reference iron plate, measuring circuit, and the structure of probe is referring to accompanying drawing, and its structure is: a strain sensor 2 is installed on the pedestal 3 that metal such as copper, aluminum etc. of non-ferromagnetic material makes, The direction of the strain sensor 2 is parallel to the bottom surface of the base 3. One end of the strain sensor 2 is fixed on the foot of the base 3, and the other end is suspended in the air. A magnet 1 is installed above. The poles of the magnet 1 face up and down, and the magnet 1 is perpendicular to the strain gauge. The sensor 2 is also perpendicular to the bottom surface of the base 3 .

[0012] A bubble level 7 is also installed on the upper surface of the base 3, and the reference plane of the level is parallel to the bottom surface of the base for adjusting the level during measurement.

[0013] The strain sensor 2 is electrically connected with the measuring circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com