Loose detecting device for arm support bearing cap

A technology of cone crusher and detection device, which is applied to measurement devices, electrical devices, and testing of machine/structural components, etc., can solve problems such as falling off, unfavorable discovery problems, and remote observation positions for personnel, and achieves low product manufacturing costs. The effect of improving observation accuracy and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

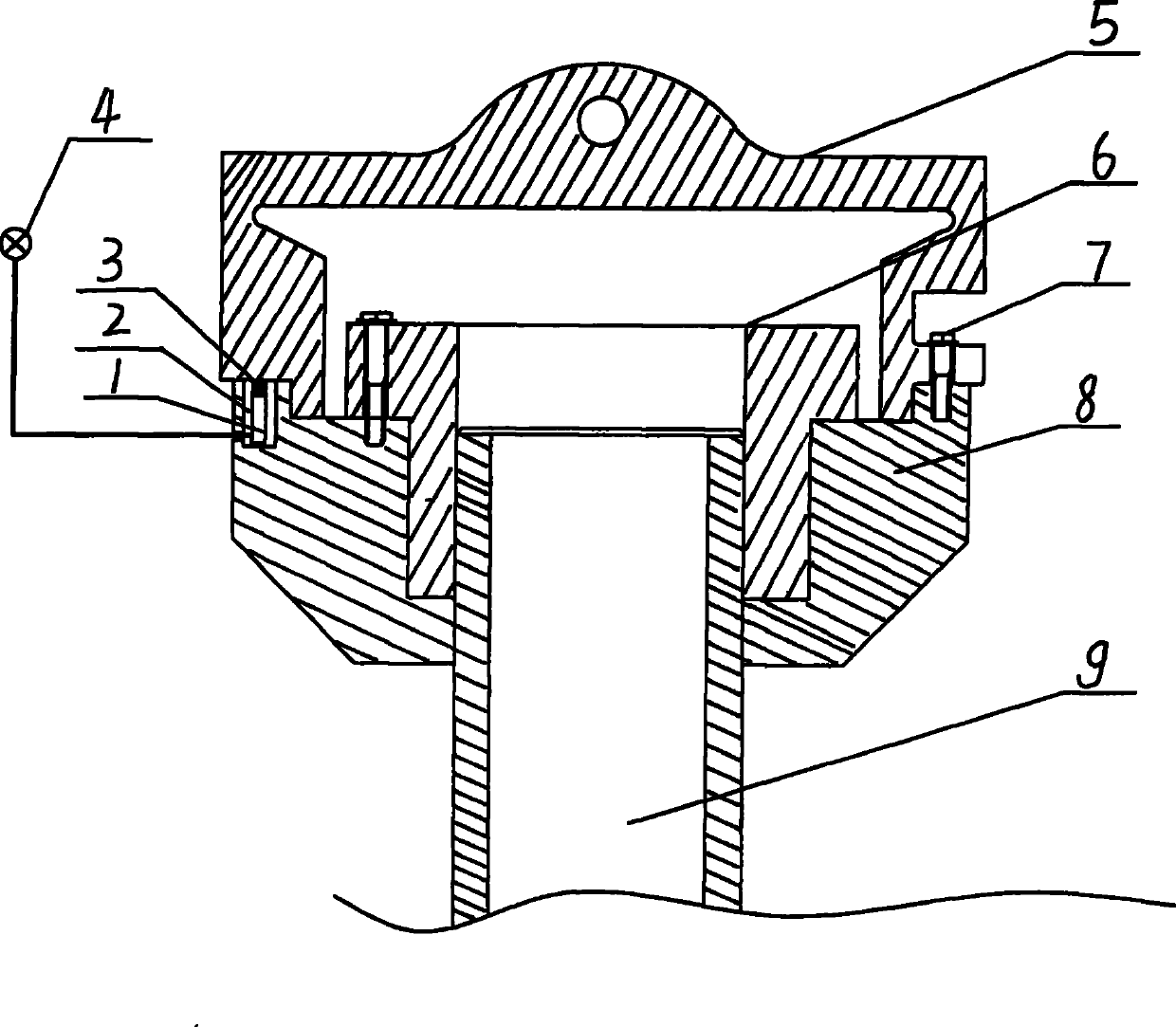

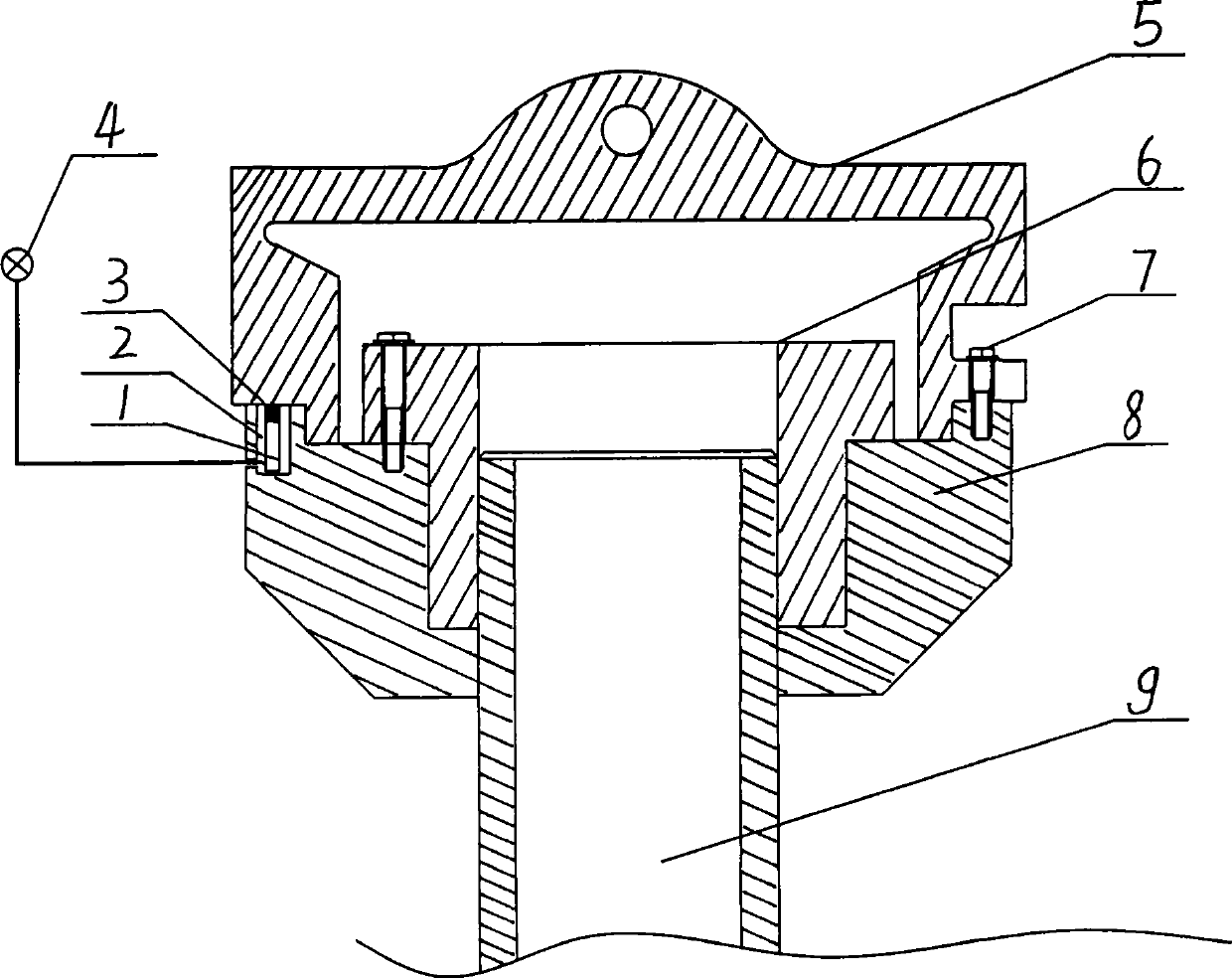

[0009] Such as figure 1 As shown, the boom bearing cover 5 is connected with the boom bearing seat 8, and the boom bearing 6 is fixed inside the boom bearing seat 8. Open a hole 2 of Ф30mm and length 90mm, and open a gap of Ф10mm on the outer wall of the boom bearing seat 8 to communicate vertically with one end of the hole 2. Install a SI08 / SS08 type proximity switch 1 with a diameter of 8mm in the hole 2 to make the The switch 1 is fixed on the boom bearing seat 8, and one end of the proximity switch 1 has a detection head 3. Adjust the detection head surface of the proximity switch 1 to be level with the horizontal plane in contact with the boom bearing seat 8 and the boom bearing cover 5, and place the boom bearing Cover the cover 5, connect with the boom bearing seat 8 with the screw 7, the probe head 3 is in contact with the boom bearing cover 5, there is a wire on the proximity switch 1 passing through the gap to connect the signal lamp 4, and the signal lamp 4 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com