Steam type first-class lithium bromide absorption type heat pump units with dual-effect refrigeration function

A lithium bromide absorption and heat pump unit technology, which is applied in refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve problems such as waste and high-grade energy consumption, and achieve energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

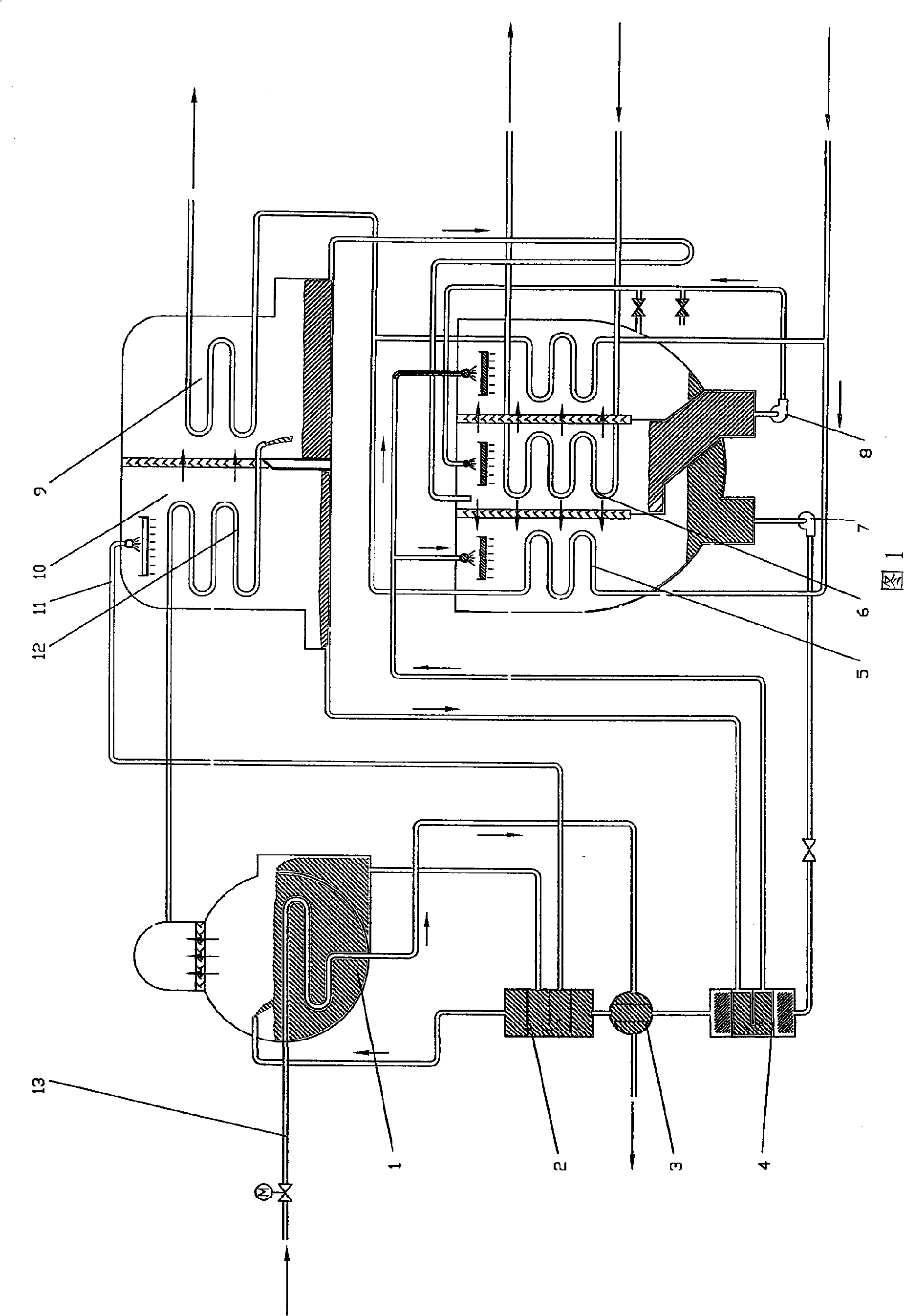

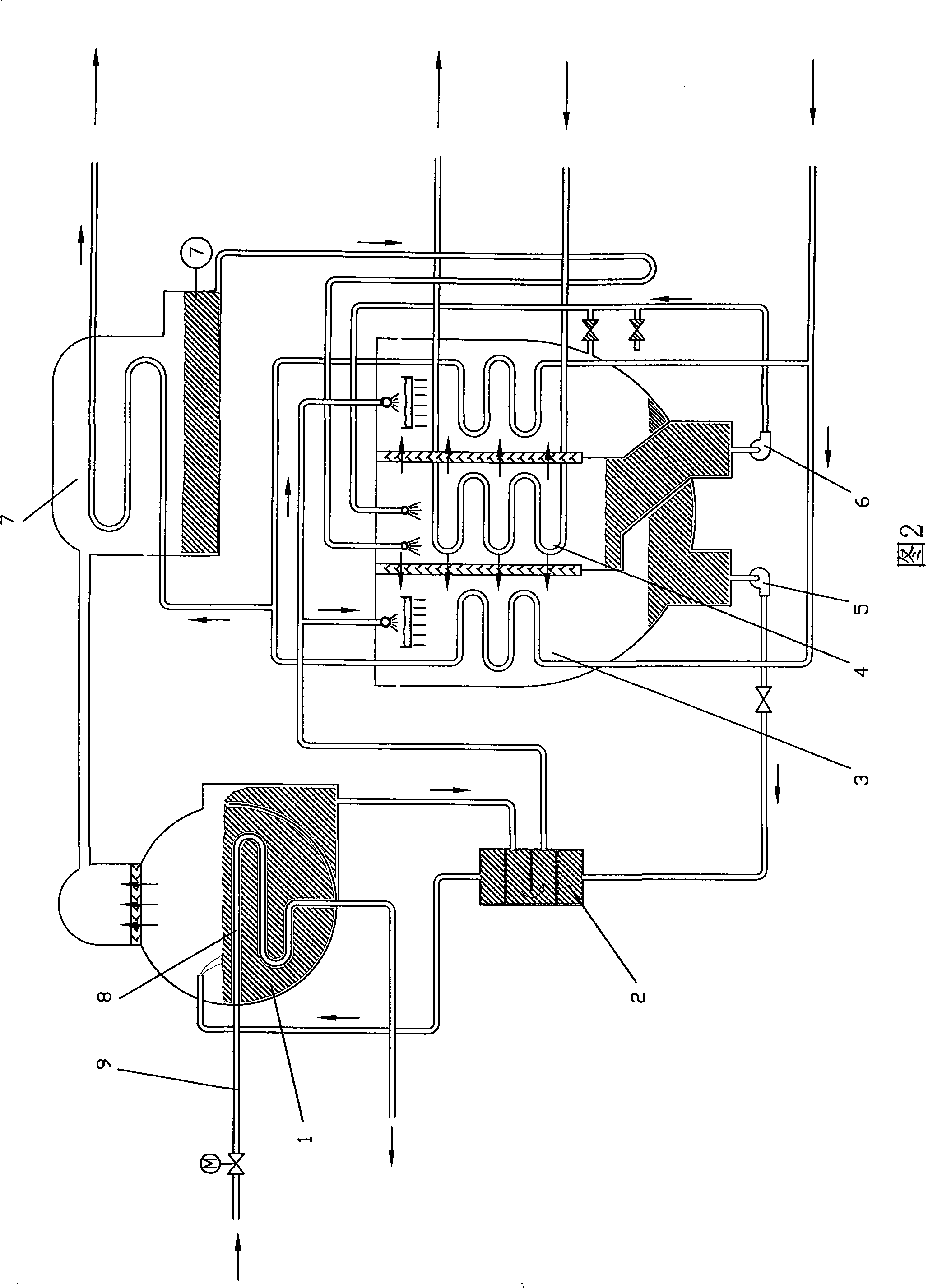

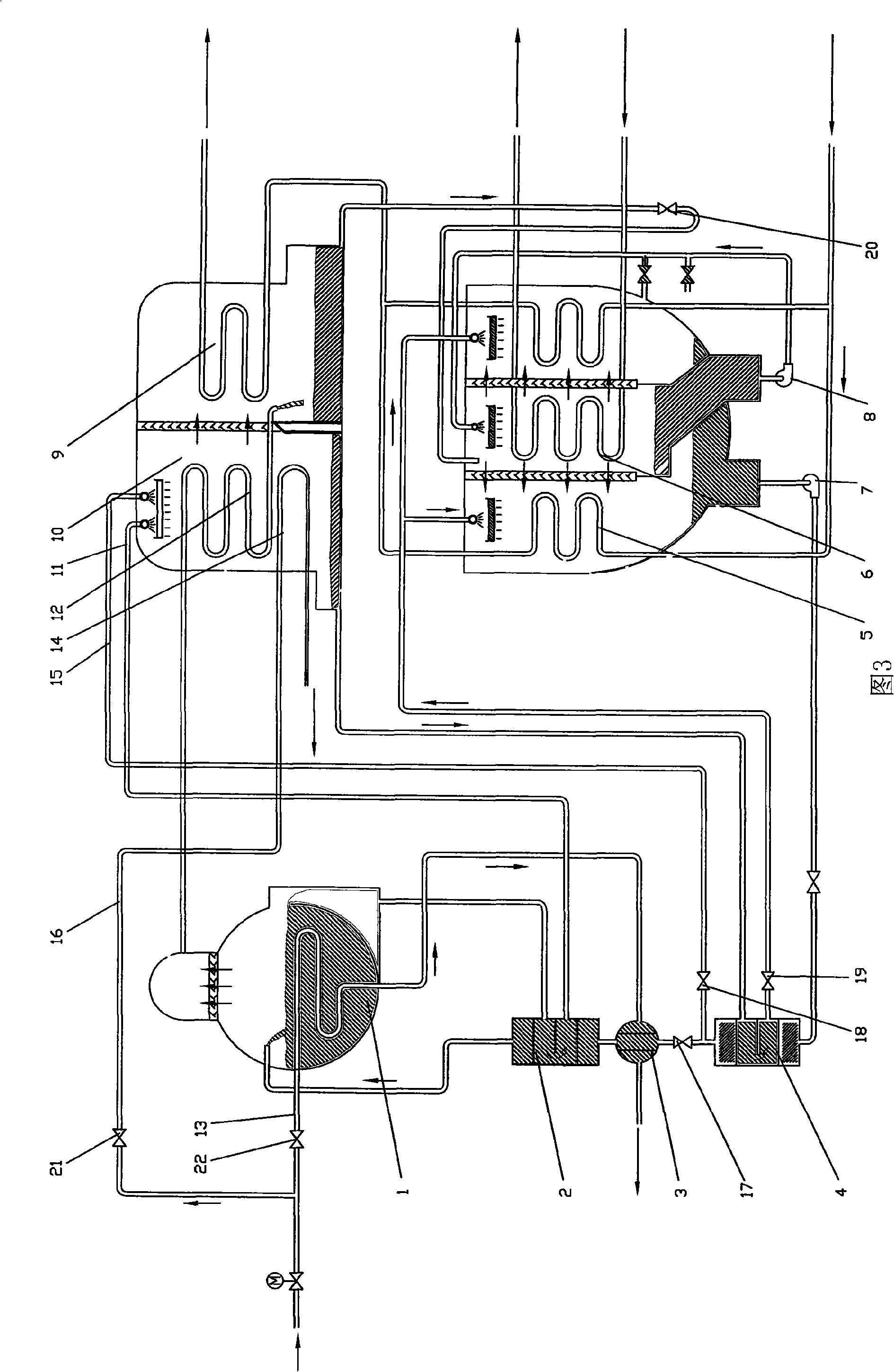

Embodiment 1

[0016] The unit shown in Figure 3, this unit is based on the previous steam double-effect lithium bromide absorption chiller shown in Figure 1, and the steam heat exchange tube bundle 14 of the steam generator of the steam type first lithium bromide absorption heat pump shown in Figure 2 and the low-efficiency heat exchange tube bank 12 of the low-pressure generator are placed in a cylinder to form a composite generator 10, and the steam heat exchange tube bank 14 and the low-efficiency heat exchange tube bank 12 are arranged up and down. The solution heat exchanger and the low-temperature solution heat exchanger of the heat pump share a low-temperature solution heat exchanger 4 . The unit consists of a steam high-pressure generator 1, a composite generator 10, an evaporator 6, an absorber 5, a condenser 9, a high-temperature heat exchanger 2, a condensate solution heat exchanger 3, a low-temperature solution heat exchanger 4, and a solution pump 7 . Refrigerant pump 8. Steam-...

Embodiment 2

[0017] Embodiment 2: As shown in Figure 4, on the basis of Invention 1, the steam heat exchange tube bundle 14 and the low-emission heat exchange tube bundle 12 are arranged left and right. In the heating mode of the heat pump, the dilute solution is sprayed onto the steam heat exchange tube bundle 14 through the dilute solution entering composite generator spray pipe 15 . In the double-effect cooling mode, the intermediate solution from the high-pressure generator 1 enters the spray pipe 11 of the composite generator through the intermediate solution and sprays onto the low-fire heat exchange tube bundle 12 in the composite generator 10 .

[0018] The above scheme is applicable to the two-stage type of condenser, evaporator and absorber. Hot water (cooling water) parallel flow, series flow. The driving heat source can be not only steam, but also high-temperature hot water, heat transfer oil, etc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com