Battery thermal management system for vehicle

A battery thermal management and vehicle technology, applied in the field of vehicle battery thermal management system, can solve the problems of poor cooling effect, high cost, high energy consumption, etc., and achieve the effect of prolonging service life, good cooling effect and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

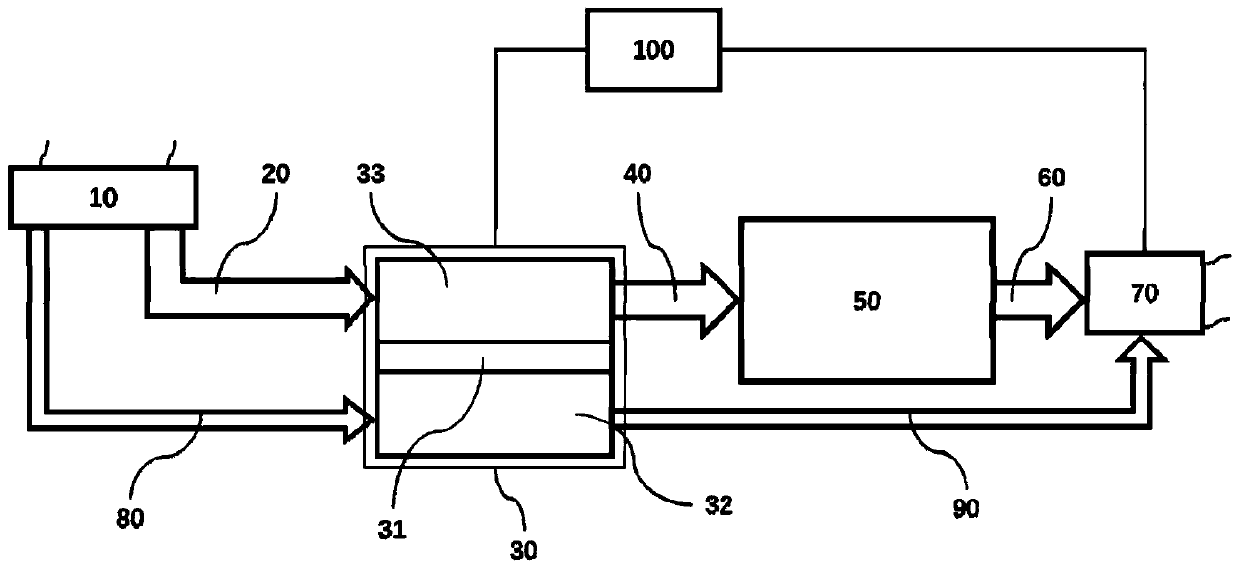

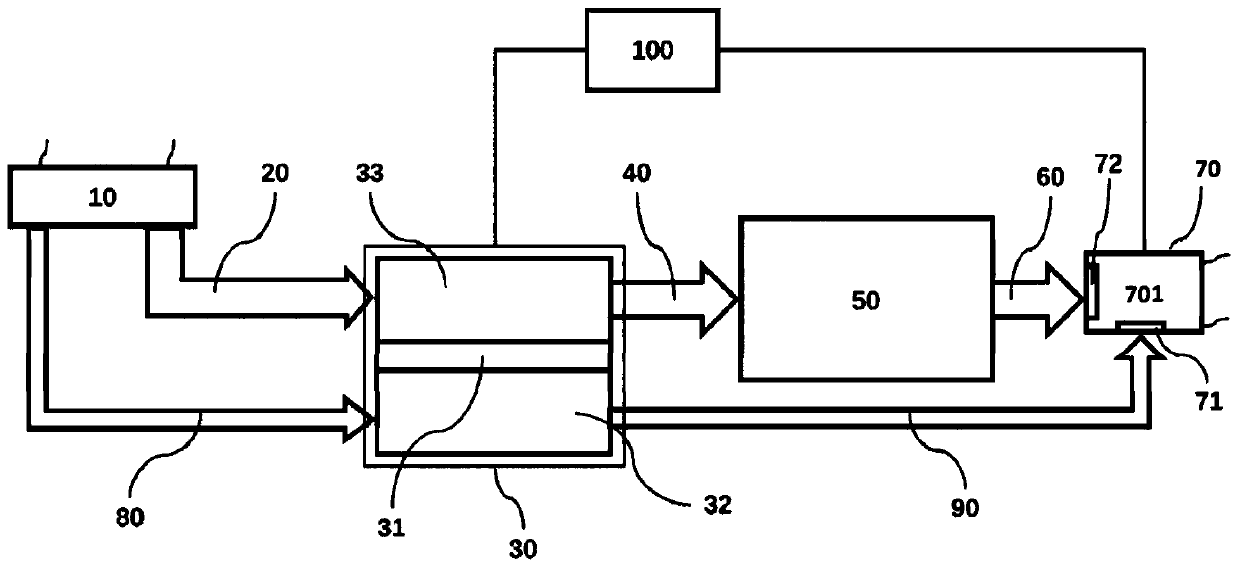

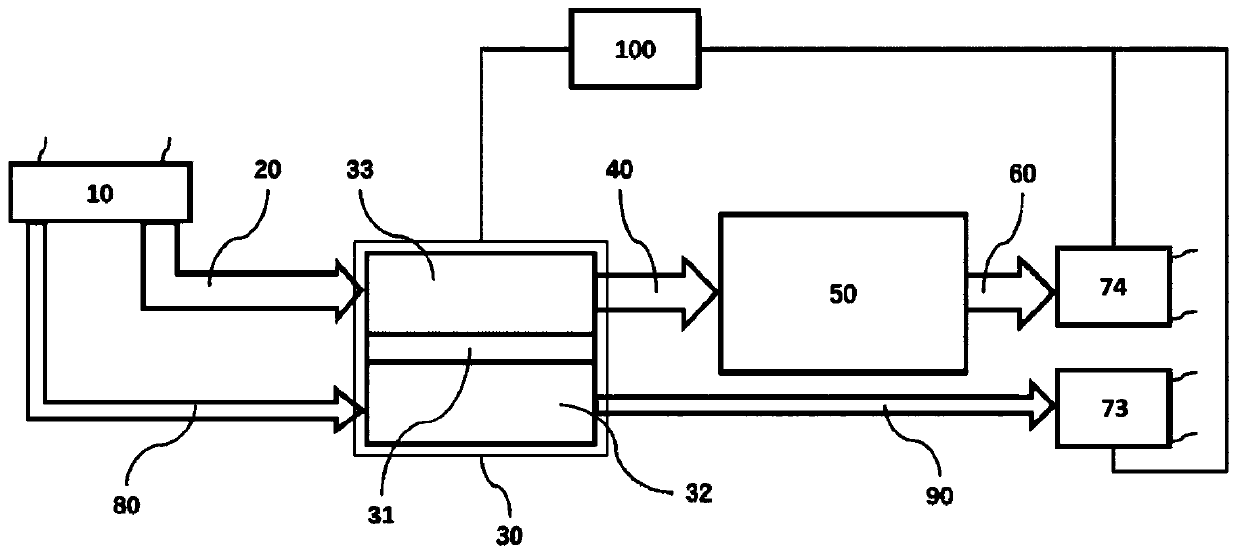

[0039] figure 1 is a schematic structural diagram of a battery thermal management system according to an embodiment of the present invention. Such as figure 1 As shown, the present invention provides a vehicle battery thermal management system, which may generally include a thermoelectric semiconductor heat exchange unit 30 , a battery pack 50 , a fan unit 70 and a control unit 100 . The thermoelectric semiconductor heat exchange unit 30 includes a thermoelectric semiconductor 31 , a first air heat exchanger 33 and a second air heat exchanger 32 respectively disposed on opposite first and second ends of the thermoelectric semiconductor 31 . Here, the first end and the second end refer to the heat exchange ends of the thermoelectric semiconductor 31, for example, when a preset voltage is applied to the thermoelectric semiconductor 31, the first end starts to cool while the second end starts to heat; When the preset voltage is applied to the thermoelectric semiconductor 31, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com