Total heat recovery combustion gas-air energy composite heat pump hot-cold combined supply unit

An air-energy heat pump, combined cooling and heating technology, applied in heat recovery systems, refrigerators, refrigeration components, etc., can solve the problems of reduced heating capacity and heating performance coefficient, difficulty in cooling capacity and heating capacity, and inapplicability , to achieve the effect of being conducive to environmental protection, reducing nitrogen oxides, and solving efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

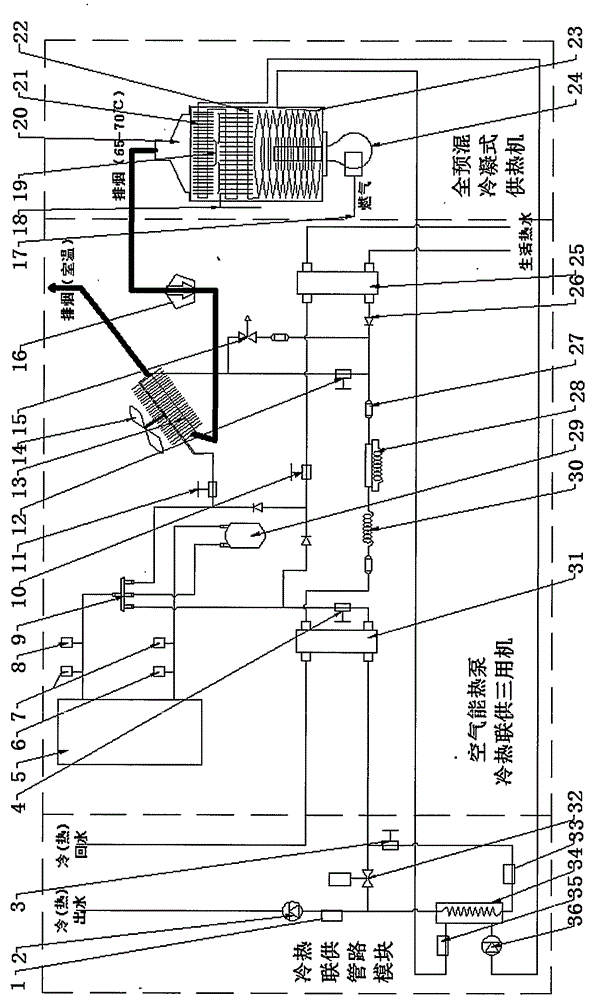

[0024] Combine below figure 1 To elaborate on the specific implementation method:

[0025] The fully premixed condensing heating machine includes gas inlet pipe 17, condensed water discharge pipe 18, condensed water collecting pan 19, smoke box 20, condenser 21, fin heat exchanger 22, coil heat exchanger 23 , full premix burner 24, and corresponding connecting pipes. The gas inlet pipe 17 is directly connected to the full premix burner 24, and a coil heat exchanger 23 is arranged around the combustion head of the full premix burner 24, and a finned heat exchanger is arranged sequentially above the coil heat exchanger 23. Heater 22, condensed water collecting tray 19, condenser 21, smoke box 20 four parts, and all are arranged on the inside of premixed condensing type heating machine. A condensate drain line 18 is connected to a condensate catch pan 19 .

[0026] Second solenoid valve 4, compressor 5, low pressure switch 6, needle valve 7, high pressure switch 8, four-way re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com