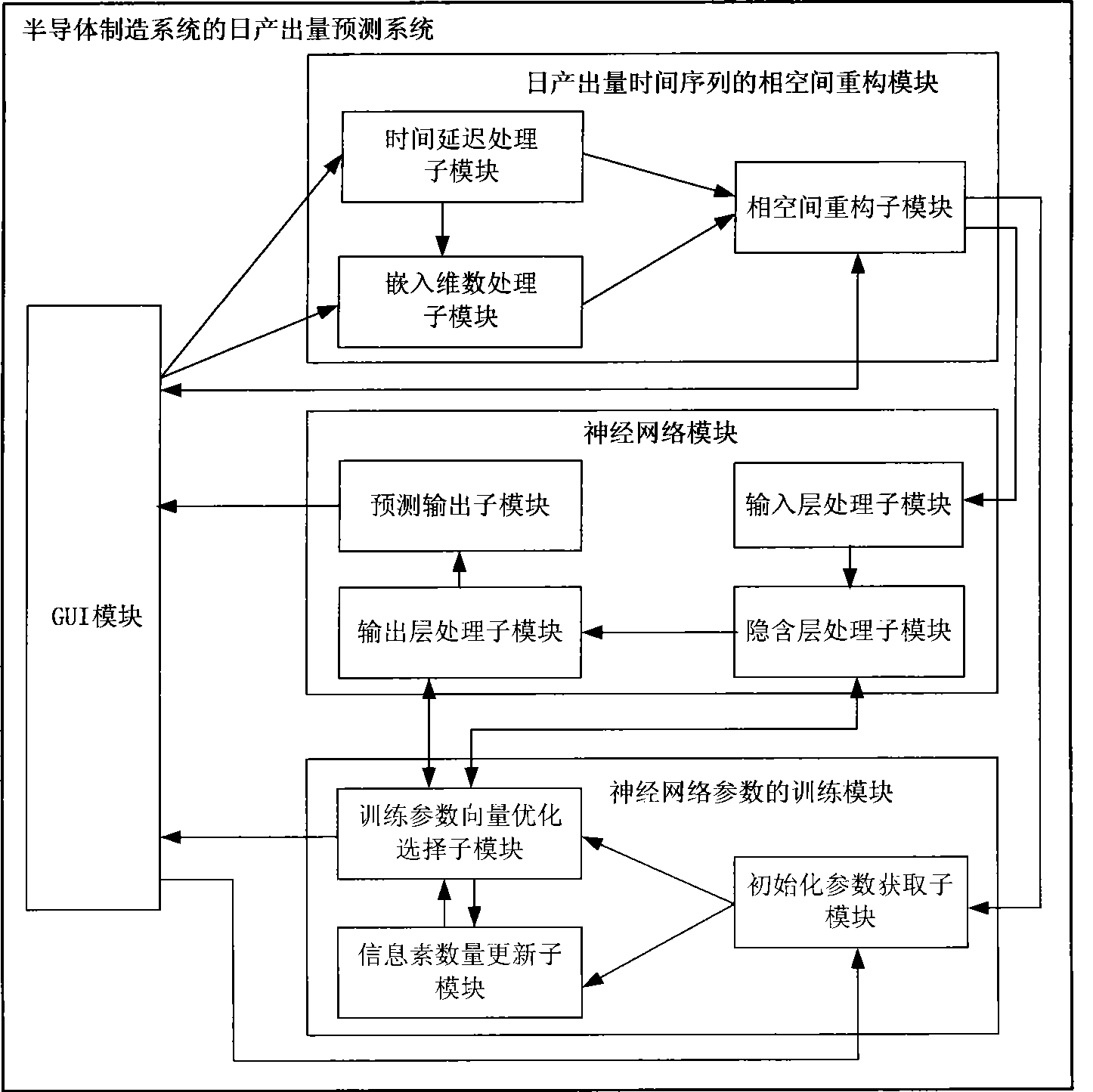

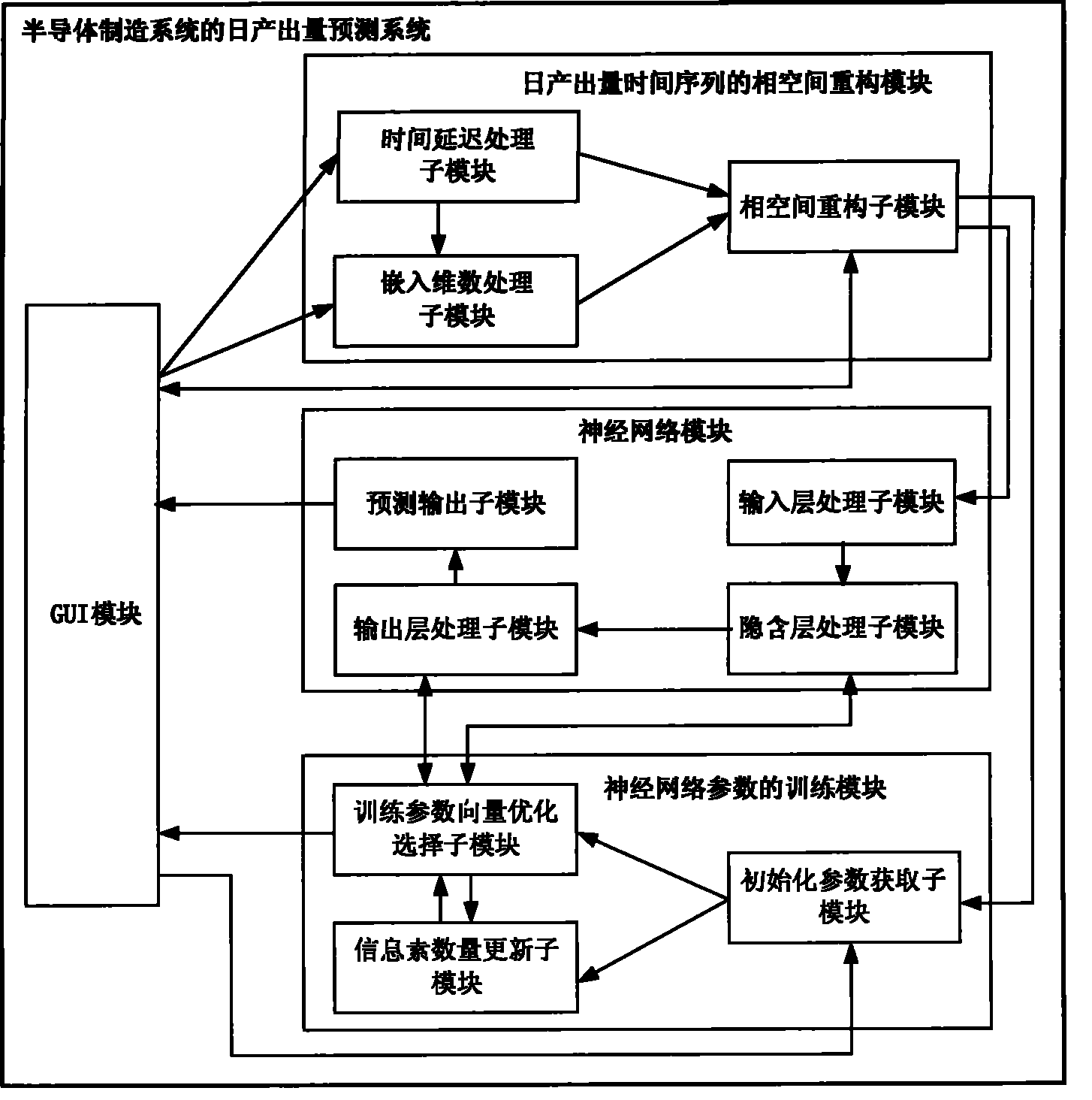

Daily throughput estimation system for semi-conductor manufacturing system

A manufacturing system and output technology, applied in manufacturing computing systems, comprehensive factory control, comprehensive factory control, etc., can solve the problem of large randomness in the selection of the input dimension of the forecasting model, unsuitable for output forecasting, and forecasting model adaptation. problems such as poor performance, to achieve the effect of fast prediction, high accuracy and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in detail: present embodiment is carried out under the premise of technical solution of the present invention, provides detailed implementation mode and specific operation process, but protection scope of the present invention is not limited to the following the embodiment.

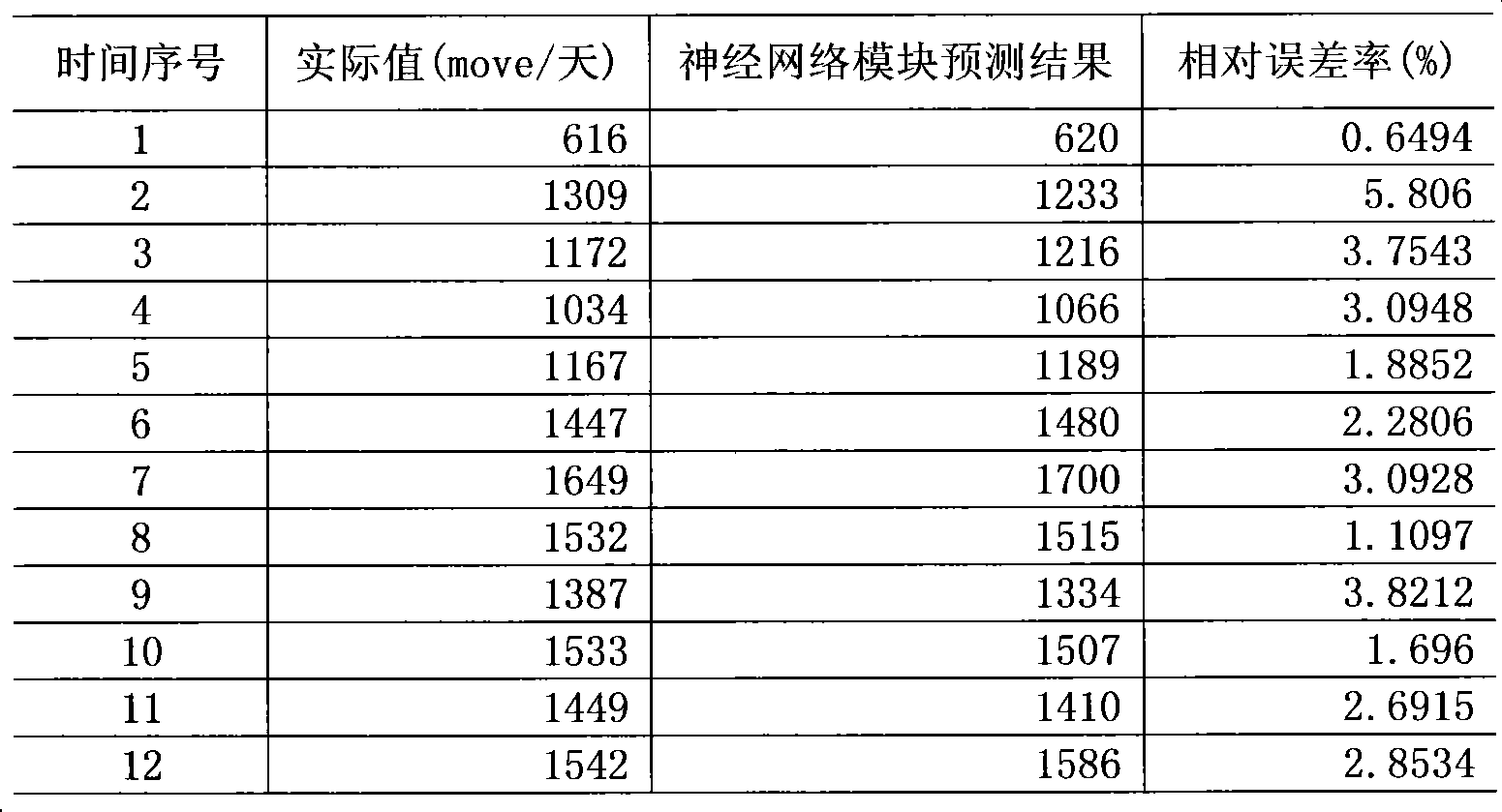

[0030] The historical data of the daily output of the semiconductor manufacturing system obtained in this embodiment forms a 90-day daily output time series as shown in Table 1.

[0031] Table 1 Sample of daily output time series

[0032] Day number

1

2

3

4

5

6

7

8

9

10

Daily output

1173

546

1475

1307

1605

1181

557

531

892

826

Day number

11

12

13

14

15

16

17

18

19

20

Daily output

315

756

475

1136

969

1163

943

599

1310

1184

Day number

21

2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com